When addressing the issue of a solar solenoid valve, understanding the underlying causes and methods for repair is essential. 1. Inspect the valve for physical damage, 2. Check electrical connections for continuity, 3. Clean or replace the diaphragm if necessary, 4. Test for proper functionality after repairs. A detailed approach to each of these key areas can prevent future problems and ensure efficient operation of solar irrigation systems. For instance, inspecting for physical damage can reveal if external elements have compromised the valve, leading to leaks or malfunctions. Addressing these key points systematically promotes longevity and performance in solar solenoid valves, which are crucial for automated watering systems.

1. UNDERSTANDING SOLENOID VALVES

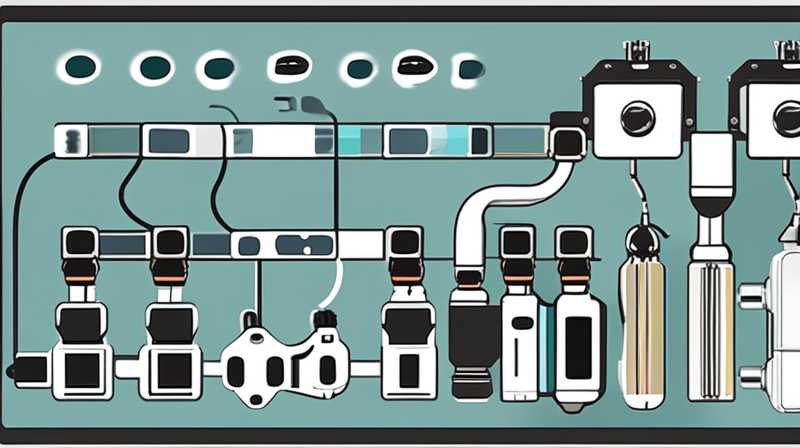

A solar solenoid valve plays a pivotal role in managing the flow of water in irrigation systems, particularly in regions prone to water scarcity. These devices work by using an electromagnetic coil to transmit a signal that opens or closes a valve, thereby regulating irrigation schedules based on solar power. Understanding their construction and function is essential for effective maintenance. Solenoid valves generally consist of a coil, a plunger, and a valve body. When electrical current passes through the coil, it generates a magnetic field that pulls the plunger upwards, which either opens or closes the valve.

Moreover, one should recognize that solenoid valves can be sensitive to a variety of factors including pressure changes, temperature fluctuations, and dirt accumulation within the mechanism. Factors such as these can lead to valve malfunction, resulting in irregular water flow. Regular checks ensure built-in cleaning devices or filters are functioning correctly to mitigate the adverse effects of debris and sediment that can obstruct proper valve operation. Thus, a thorough understanding of the components involved allows for better diagnosis and repair strategies when faced with malfunctions.

2. INSPECTING PHYSICAL DAMAGE

It’s vital to initiate repairs by examining the valve for any visible signs of damage. Cracks, leaks, or corrosion can significantly impede its operation. Begin by visually inspecting the body of the valve for any fractures or missing elements. A damaged exterior may indicate that the internal components are also compromised. Areas that are exposed to environmental stress or harsh conditions are particularly susceptible to wear and tear.

In addition to external inspections, ensure connections to the water supply are intact. Loose fittings can lead to leaks that may not only affect the valve itself but can also cause other components in the irrigation system to fail. Addressing these physical faults ensures safe operation and enhances the reliability of the irrigation processes. If any physical damage is identified, immediate repairs or component replacements should be prioritized to restore functionality and to prevent further damage.

3. CHECKING ELECTRICAL CONNECTIONS

After examining the physical condition of the valve, the next critical step involves evaluating electrical connections. A malfunction in a solar solenoid valve frequently stems from connectivity issues. Checking for continuity with a multimeter can reveal intermittent connections or complete failures in the circuit. It’s essential to inspect the wiring for any fraying, corrosion, or breaks that may disrupt the signal from the solar controller to the valve.

Once the wiring is scrutinized, verify the solenoid coil itself. A coil that is open or shorted will require replacement. Understanding the characteristics of the electrical components is vital for anyone working on solenoid valves. Once electrical integrity is confirmed, testing the connections through an operational check will ensure that commands are being accurately relayed from the solar controller, allowing for proper valve operation.

4. CLEANING OR REPLACING THE DIAPHRAGM

Another critical aspect of maintaining solar solenoid valves is addressing the diaphragm, which is pivotal in regulating the opening and closing of the valve. A buildup of sediment and organic matter can lead to malfunctions in diaphragm function. To clean the diaphragm, ensure the valve is powered off and shut off the water supply. Disassemble the valve carefully, taking note of the order of components for reassembly.

Once disassembled, use a soft brush and mild cleaning solution to remove any dirt or residue. Avoid abrasive materials that could damage the diaphragm. In cases where the diaphragm is severely worn or cracked, a replacement is necessary. Verify that the new diaphragm is compatible with the specific model of the solenoid valve being repaired. Proper dosing when reassembling will guarantee that the valve regains its original functionality, ensuring efficient operation for future watering cycles.

5. TESTING FOR PROPER FUNCTIONALITY

After addressing physical, electrical, and internal components, the final step involves thorough functional testing of the solenoid valve. Power the system back on and observe the valve during its operation, ensuring that the opening and closing mechanisms work smoothly without any hitches. Check to see whether the valve responds appropriately to commands from the solar controller. A well-functioning solenoid valve should engage promptly and without noise, indicating that all components are working in harmony.

In the case of any issues during testing, a systematic approach to troubleshooting would again involve revisiting each component that has been addressed. Through careful observation and methodical examination, one can identify any lingering issues and rectify them promptly. Successful testing confirms that the solar solenoid valve is ready to reintegrate into the irrigation system, maximizing its efficiency in conserving water while providing necessary hydration to plants.

FAQs

WHAT ARE COMMON SIGNS OF A MALFUNCTIONING SOLENOID VALVE?

Recognizing the signs of a malfunctioning solenoid valve is imperative in maintaining an effective irrigation system. Some prevalent indicators include irregular water flow, constant dripping, or complete non-responsiveness when triggered. Visually inspecting the valve may also reveal physical issues such as cracks or corrosion. Excessive noise during operation can be a sign of mechanical failure inside the valve, indicating that internal components such as the diaphragm may need servicing.

Furthermore, if the system fails to engage the valve during its scheduled operation, it could signify electrical faults within the connections or problems with the solar controller. To diagnose problems effectively, users should keep a comprehensive log of the valve’s performance to identify patterns that lead to malfunction. Regular inspections based on these signs will ensure timely interventions to address the issues before they escalate further, contributing to the overall efficiency of the watering system.

HOW OFTEN SHOULD SOLENOID VALVES BE MAINTAINED?

Maintenance frequency for solenoid valves largely depends on various factors such as system usage, environmental conditions, and specific operational demands. Generally, it is advisable to perform a thorough check at least once every season—or more often in areas with extreme weather variations or heavy use. During these inspections, checking for physical damage and ensuring that the valve is operating smoothly should be prioritized.

In addition to seasonal checks, users should also perform regular visual inspections as part of their routine irrigation practices. This proactive approach helps ensure any emerging issues are addressed early on, minimizing potential downtime due to valve failure. Should significant demands be placed on the irrigation system, increased frequency of inspections may be warranted. Comprehensive maintenance guarantees that solenoid valves function properly, ensuring their efficiency in conserving water while delivering hydration to the plants.

IS IT POSSIBLE TO REPAIR A SOLENOID VALVE?

Repairing a solenoid valve is indeed possible and can often be accomplished without replacing the entire unit. Key repair measures typically include addressing physical damage, electrical connections, and internal components such as the diaphragm. This process often begins with a comprehensive inspection to identify the root cause of any issues, followed by targeted repairs tailored to the problem identified.

If the valve exhibits physical signs of wear, such as cracks, it may be replaced. However, cleaning and repairing electrical connections are routinely manageable tasks that require basic tools and an understanding of electrical principles. Additionally, diaphragms that have become worn or clogged can be serviced with relative ease. By adequately diagnosing and addressing issues based on their nature, effective repairs can restore the valve to proper working condition, thereby prolonging its operational lifespan significantly.

Effective procedures to maintain, repair, and understand solar solenoid valves empower users with the knowledge to ensure optimal functionality. The structured approach to inspecting and addressing damage underscores the importance of a proactive maintenance plan. Inspection includes looking for visual signs of damage, checking electrical connections for integrity, and cleaning or replacing crucial internal components such as the diaphragm. Testing the valve assures continued functionality. Such in-depth knowledge creates an enhanced understanding of the system, fosters responsible practices, and contributes to sustainability through efficient water management. By embedding thorough inspection and maintenance protocols into regular practices, users can ensure that solar solenoid valves operate efficiently, thereby positioning themselves for greater success in sustainable irrigation endeavors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-fix-the-solar-solenoid-valve/