To effectively resolve issues with the rounded tube of solar lighting fixtures, several actionable strategies exist that can rejuvenate functionality and aesthetics. 1. Determine the nature of the damage, 2. Gather appropriate materials, 3. Apply repair techniques, 4. Test the fixture thoroughly. The first step, identifying whether the damage is a crack, bend, or complete break, is pivotal, as it dictates subsequent actions and materials needed. Emphasis should also be placed on ensuring all repair procedures are conducted with care to maintain the structure’s viability and appearance.

1. UNDERSTANDING THE STRUCTURE

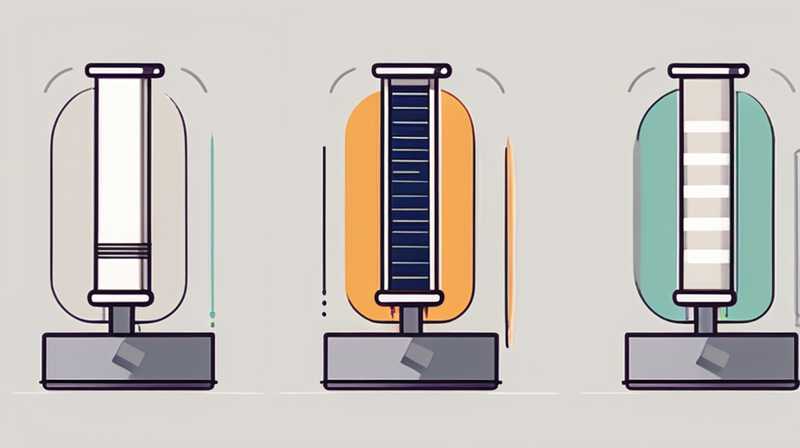

Understanding the fundamental composition of solar lighting is essential for troubleshooting. Most solar lights comprise various components, including plastic or metal tubes, solar panels, LEDs, and rechargeable batteries. The rounded tube, serving as the main body, houses these components while providing structural integrity and aesthetic appeal. Often, the tube is manufactured from durable materials like polycarbonate or aluminum, which can withstand outdoor conditions.

Failures in these tubes can arise from environmental factors, physical damage, or wear and tear. Environmental influences such as intense sunlight, heavy rain, and extreme temperatures can gradually weaken the material. Meanwhile, physical damage from accidents, such as falls or impacts, can lead to breaks that compromise the entire system. Recognition of these factors allows for a more directed approach in addressing and fixing the issues.

2. ASSESSING DAMAGE

Before undertaking any fix, an assessment of the tube’s condition is paramount. Check for visible cracks, dents, or deformities along its length. Moreover, ensure that the internal components remain in working order, as damage may not solely be external. Also, testing the solar panel for functionality can provide insight into the extent of the issues.

When cracks appear, they might not only affect the tube’s appearance but can also lead to internal deterioration due to the penetration of moisture. Identify whether the damage is superficial or if it compromises structural integrity. For dents, assess whether the light fixture maintains proper alignment, as improper alignment could hinder performance. Additionally, consider the light’s overall age and exposure levels. This understanding can guide repair, determining whether a quick fix suffices or if a complete replacement seems more appropriate.

3. GATHERING REPAIR MATERIALS

Selecting appropriate materials is critical to execute repairs effectively. Most repairs may require common household items, including adhesives, sealants, and tape. For more extensive damage, consider procuring parts such as a new tube or fixture entirely. Among the most useful materials are waterproof epoxy or super glue, which can bond cracks effectively while resisting moisture.

For bends, a heat source might be utilized to soften the material, allowing for reshaping. Special considerations must be taken regarding adhesives, especially if the area exposed to the weather. Waterproof options will ensure longevity for the repair. Tools such as sandpaper, scissors, and a heat gun may also be required. Compiling these resources forms a toolkit necessary for restoring functionality amid varying levels of damage. Preparedness in this area can significantly streamline the repair process.

4. REPAIR OPTIONS

Choosing the appropriate repair method depends largely on the type of damage. For cracks, a strong adhesive is typically the most effective solution. Clean the affected area thoroughly, ensuring that no dirt or moisture interferes with the adhesive’s bonding quality. Once cleaned, evenly apply the adhesive along the crack, then press the sides together firmly. Depending on the product used, clamping the tube for several hours may enhance the adhesive’s strength.

For substantial breaks, consider a multi-step process that involves reinforcing the damaged area with a patch. This patch could be made from a similar material or heavy-duty tape that bridges gaps effectively. Applying a waterproof sealant over the patch can enhance durability and guard against moisture fallout. If you encounter severe bends, applying heat with a heat gun can make the material pliable, facilitating correction. Gradual cooling will help maintain the newly shaped structure.

5. TESTING THE FIX

After performing repairs, a thorough testing phase is vital to ensure all functions operate optimally. Place the solar light back in its intended location, allowing it to charge under sunlight. Monitor the light’s performance during the evening hours to confirm efficacy. Keep an eye on illumination intensity and duration, noting whether the light operates as expected.

Regular observations over the following days can provide insights into the result of repairs, assessing if further adjustments are needed. If the reparative actions remain unsuccessful, reconsider the methods or materials utilized. Understanding what aspects require ongoing maintenance can ultimately prolong the lifespan of the solar fixture while enhancing performance.

6. MAINTAINING SOLAR LIGHTS

Ongoing maintenance is crucial for preserving solar lighting over time. Routine inspections for cracks and dirt buildup are essential, as neglect can lead to issues inhibiting function. Cleaning the solar panel’s surface ensures optimal sunlight intake, significantly impacting the battery’s charging capabilities. Additionally, removing debris and dirt around the fixture facilitates unhindered performance.

Regularly checking the battery for efficiency is also recommended. If the light exhibits dimness despite a full charge, consider replacing the battery. Inspection for corrosion or wear on electrical components can help avoid further issues down the road. Implementing these practices establishes a preventive maintenance routine that will save time and expense, ultimately enhancing the longevity of solar fixtures.

SOLAR LIGHT MAINTENANCE

What are common issues with solar lights?

The frequent problems associated with solar lights include insufficient brightness, diminished charging abilities, and physical damage. Insufficient brightness often stems from dirty solar panels or old batteries unable to hold a charge. Additionally, environments with limited sunlight can hinder the effectiveness of solar power.

How can one improve solar light performance?

Improving solar light performance can involve regular cleaning of the solar panel, replacing worn-out batteries, and ensuring that the light is positioned in an area that receives ample natural sunlight. Furthermore, avoiding obstruction from plants or structures contributes to improved functionality.

What should be done for completely broken solar lights?

When solar lights are irreparably damaged, consider assessing whether component parts can be salvaged. If feasible, replace only the broken parts rather than the entire fixture. In scenarios where a complete overhaul is necessary, research replacement options that align with existing fixtures. External reviews can also help identify reliable brands for renewed installations.

Regularly maintaining solar lights can mitigate severe damage and extend their lifespan. This works toward maintaining an aesthetically pleasing environment and ensuring efficient functionality, demonstrating genuine mindfulness regarding natural resource usage.

Repairing the round tube of solar lighting requires a methodical approach focusing on assessing damage, selecting suitable materials, and utilizing effective repair strategies. Implementing quality adhesives and consistent maintenance practices can significantly enhance durability. Furthermore, continual attention to performance ensures that your solar lights remain operational across seasons. Investing time and resources into maintaining solar fixtures recognizes the genuinely eco-friendly nature of these systems, as they depend predominantly on renewable energy sources. As a result, enhanced craftsmanship and routine assessments will lead to prolonged function and minimized expenses over time.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-fix-the-round-tube-of-solar-light/