To fix the pipes of solar energy barrels, one must understand several key factors: 1. Identify the problem accurately, 2. Gather necessary tools and materials, 3. Execute repairs with precision, 4. Ensure long-term functioning by conducting regular checks. The initial step involves diagnosing any leaks, blockages, or damage, which requires a thorough inspection of all connections and sections of the piping. Accumulation of debris or corrosion is common in solar energy setups, necessitating careful examination. Once the issue is understood, gather all tools, such as wrenches, sealants, and cleaning equipment. Employing the right techniques to fix these problems is critical, as improper methods may lead to recurring issues. Furthermore, implementing a routine maintenance schedule is essential to prevent future complications. Regular inspections will help in detecting potential concerns before they escalate, ensuring the efficiency of the solar energy system.

1. UNDERSTANDING SOLAR ENERGY BARRELS

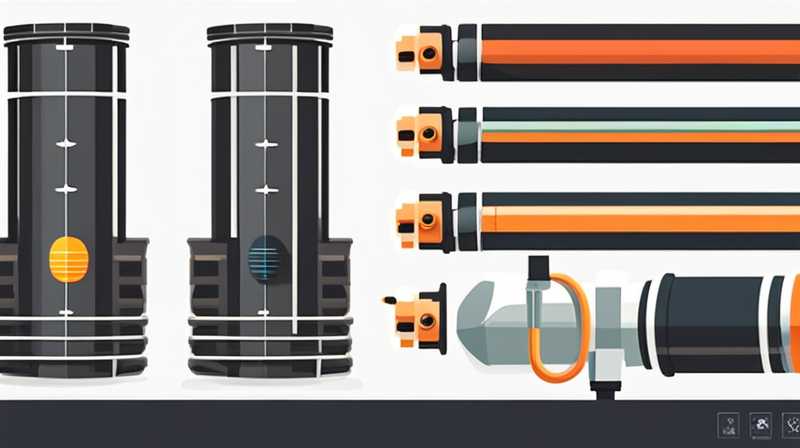

Solar energy barrels play a crucial role in harnessing renewable energy for various applications. These systems typically collect and store thermal energy and can be integrated into larger solar infrastructure. The operational efficiency and longevity of solar energy barrels largely depend on the integrity of their piping systems. When problems arise in the pipes, it can significantly hinder the overall performance, resulting in increased energy costs or even complete system failure.

The primary function of these pipes is to transport fluid, which absorbs heat from the sun. Any obstruction or damage can lead to inadequate heat transfer, which directly affects energy production. This illustrates the importance of ensuring that all plumbing connected to these systems is functioning optimally. In the subsequent discussions, various techniques and methods for fixing common issues encountered in solar energy barrel systems will be examined.

2. IDENTIFICATION OF COMMON ISSUES

Establishing what specific problems are present in the piping of a solar energy barrel is the first and most crucial step in the repair process. Many issues can arise, including leaks, blockages, and wear caused by environmental factors. For instance, leaks may occur due to joint failures, corrosion, or accidental damage caused during maintenance. Identifying the exact point of leakage is vital, as it can help in determining whether the repair is a simple fix or if a more complex intervention is required.

Blockages can occur when debris accumulates within the system, preventing the flow of fluid necessary for heat transfer. This can be particularly problematic in systems that utilize open-loop designs, where water is directly drawn from natural sources. Thus, regular cleaning and maintenance of these pipes should be prioritized to ensure uninterrupted operation. Recognizing these common issues lays the groundwork for successful remediation, reducing downtime and enhancing overall efficiency.

3. TOOLS AND MATERIALS REQUIRED

Equipping oneself with the appropriate tools and materials is paramount when engaging in plumbing repairs for solar energy barrels. The right set of tools ensures efficiency in repairs and contributes to the durability of the solutions implemented. Essential tools may include pliers, adjustable wrenches, screwdrivers, and pipe cutters, among others. Additionally, obtaining high-quality sealants and compatible pipe fittings is necessary for overcoming specific challenges.

When selecting sealants, it is important to choose products that are designed for high-temperature applications, as the fluid circulating through the pipes can reach elevated temperatures. Likewise, replacing damaged sections of piping with materials that are resistant to corrosive effects, such as PVC or stainless steel, will promote longevity. By gathering all necessary tools and high-quality materials before beginning the repair process, one can avoid unnecessary interruptions and ensure that repairs are executed efficiently and effectively.

4. EXECUTING REPAIRS WITH PRECISION

Having identified the issues and gathered all necessary tools, the next phase involves executing repairs. Addressing leaks, for example, often requires cutting out the damaged section and replacing it with a new segment. This involves measuring the existing pipe accurately to ensure a correct fit. Once the new piece is secured, applying adequate sealant to joints is key to preventing future leaks.

Blockages often necessitate employing various cleaning techniques to restore flow. In many cases, using a plumbing snake can effectively dislodge debris without damaging the pipe. Alternatively, applying high-pressure water jets may be necessary in severe cases. Proper execution in the repair stage can make a significant difference in the long-term performance of the solar energy barrel.

5. MAINTAINING LONG-TERM FUNCTIONING

To ensure the solar energy barrel system continues to function optimally after repairs, adopting a routine maintenance plan is essential. Regular inspections allow for early identification of potential problems, such as pipe wear or connections beginning to corrode. Integrating annual checks with a thorough examination of joints, connections, and the overall integrity of the system serves to mitigate issues before they evolve into unmanageable failures.

Additionally, homeowners or facility managers should maintain a schedule for cleaning the pipes and surrounding components. This can be integrated into routine maintenance tasks to help in preserving system longevity. Effective and consistent maintenance ensures that any concerns can be addressed swiftly, enabling the solar energy barrel to operate efficiently throughout its lifespan.

6. TRAINING AND PROFESSIONAL SUPPORT

No matter the level of expertise, seeking training or professional support for intricate plumbing systems can be beneficial. Many institutions offer workshops focused on renewable energy systems and maintenance. Equipping oneself with a comprehensive understanding of solar energy setups not only enhances one’s skills but also boosts confidence in addressing potential issues.

Professional assistance may be advisable for more complex problems that exceed standard repairs. Engaging qualified technicians ensures that repairs are executed in compliance with industry standards and regulations, reducing the risk of accidents or mishaps. Collaboration with professionals can also provide additional insights into enhancing efficiency and functionality within the solar installation beyond simple repairs.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT MY SOLAR ENERGY BARREL PIPES NEED REPAIR?

Detecting issues with your solar energy barrel pipes starts with observing specific signs of malfunction. One primary indicator is a visible leakage, which may manifest as water stains around areas where pipes connect or accumulate pooling water beneath the system. Another sign is decreased energy efficiency; if the renewable energy system does not generate expected amounts of heat or energy, blockages or leaks might be present. Furthermore, unusual noises such as hissing or gurgling emanating from the pipes can indicate air trapped within the system due to improper sealing or flow obstruction. Regular visual inspections of pipes can help in identifying any unusual wear and tear or damage that may necessitate immediate attention to maintain optimal functionality.

HOW OFTEN SHOULD I CHECK MY SOLAR ENERGY BARREL PIPES?

For optimal performance of your solar energy barrel pipes, periodic checks should be conducted at least twice a year. However, during particularly harsh weather conditions or after significant seasonal changes, it is prudent to perform inspections more frequently. Regular monitoring enables you to detect any potential problems at an early stage, such as identifying minor leaks or buildup of debris that could obstruct flow. Moreover, conducting checks after heavy rainfall or storms is recommended, as these events may cause damage to pipe fittings or cause debris to enter the system. Establishing a routine inspection schedule promotes a proactive approach, ensuring that the solar energy system remains efficient and reducing the likelihood of major repairs in the future.

CAN I FIX SOLAR ENERGY BARREL PIPES MYSELF, OR SHOULD I CALL A PROFESSIONAL?

Your ability to address issues involving solar energy barrel pipes largely depends on your level of expertise and the complexity of the problem. Simple repairs, such as sealing minor leaks or clearing blockages, can often be handled by individuals with basic plumbing skills. However, it is crucial to possess the appropriate tools and materials to carry out these tasks effectively. For more complicated issues – such as extensive damage, the need for specialized fittings, or diagnostic assessments – it is highly advisable to enlist the help of professional technicians. Professionals bring added experience and insights that can help ensure repairs are made in compliance with applicable standards, extending the lifespan and efficiency of solar energy systems.

IMPORTANT CONSIDERATIONS FOR SOLAR ENERGY BARREL REPAIRS

When addressing the challenges associated with solar energy barrel pipe repairs, understanding the importance of each step from problem identification to executing precise repairs is essential. Emphasizing the need for routine checks and maintenance cannot be overstated, as these actions will serve to enhance the reliability and efficiency of the entire system. Further, engaging in professional training can foster a deeper understanding of the complexities involved, potentially reducing the occurrence of issues in the first place. By strategically implementing these practices, users not only secure their investment in solar energy technology but also contribute to a sustainable energy future. Invariably, keeping a keen eye on the integrity of these pipes and addressing any concerns promptly will yield long-term benefits, ensuring robust performance of solar energy systems and optimizing their contributions towards renewable energy generation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-fix-the-pipes-of-solar-energy-barrels/