1. Exhausting a solar automatic pump involves specific procedures and considerations for optimal performance and longevity. 2. These key approaches include, draining the system properly, cleaning all components meticulously, monitoring for potential blockages, and ensuring all parts are functioning correctly. 3. Pay special attention to maintaining the solar panels, as they are crucial for effective pump operation. 4. Be aware of weather influences, because extreme conditions can impact pumps significantly. 5. It is important to consult the manufacturer’s specifications for detailed maintenance guidelines to avoid damage.

1. UNDERSTANDING SOLAR AUTOMATIC PUMPS

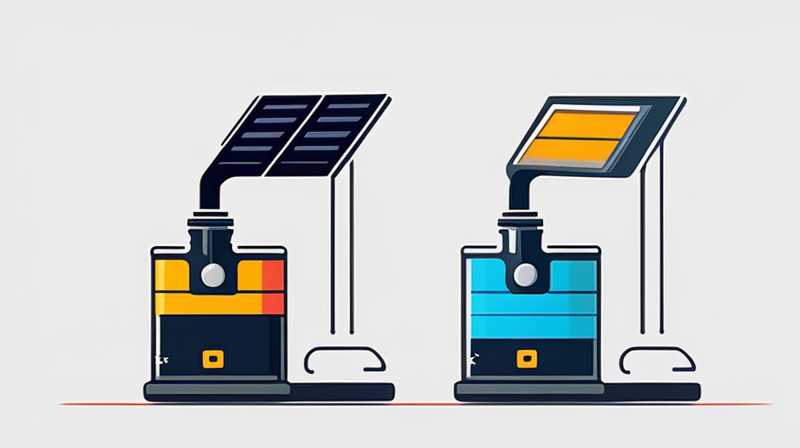

Solar automatic pumps serve as a vital resource in various applications, whether for irrigation, aquaculture, or water supply in remote areas. Unlike conventional pumps powered by electricity or fuel, solar pumps harness radiant energy from the sun, providing an eco-friendly solution. Their autonomous nature not only reduces operational costs but also promotes sustainability and independence from fossil fuels.

However, like any equipment, solar automatic pumps require diligent care to function optimally. One critical aspect of this maintenance is understanding how to effectively exhaust these systems. Exhausting a pump entails the removal of all remaining water from the system post-operation, preventing damages caused by stagnant water or freezing temperatures.

Proper exhaustion ensures longer lifespans for components, preserving the integrity of seals and avoiding rust or corrosion in metal parts. Understanding the principles underlying the exhaustion process can lead to improved performance and fewer operational interruptions over time.

2. IMPORTANCE OF ROUTINE MAINTENANCE

The necessity of routine maintenance for solar automatic pumps cannot be understated. These systems, reliant on both mechanical and electronic components, are exposed to environmental factors that may affect their performance. Regular upkeep not only extends the equipment’s lifespan but also enhances efficiency, reducing the risk of unexpected failures.

One should implement systematic checks to ensure all parts, particularly the solar panels, are maintained in pristine condition. Dust, debris, or snow accumulation can significantly hinder their ability to capture sunlight, directly affecting the pump’s functioning. Additionally, inspecting mechanical components for wear and tear ensures that issues can be addressed proactively, rather than reactively.

Moreover, the water supply system should be regularly evaluated for signs of blockage or leaks, both of which can diminish overall efficiency. Identifying and rectifying problems early on can prevent extensive damage to the pump, leading to costly repairs or replacements down the line.

3. DRAINAGE PROCESS

A methodical drainage process is paramount for ensuring that solar automatic pumps are effectively exhausted. To begin, determine the optimal method for draining water from the system. Depending on your specific setup, this may involve adjusting valves or using a manual pump to remove residual water.

Before initiating the draining process, ensure that the pump is switched off. This precaution reduces strain on the system and mitigates the risk of flooding in the event of malfunction. After shutting down, open the necessary valves to allow for water to flow out. If a drain line is present, gravity will assist in emptying the system efficiently.

Once the majority of water has been expelled, it’s advisable to inspect the insides of the pump for any lingering moisture. Using a sponge or towel can aid in ensuring that no pools of water remain in hidden spots. Completing this step is essential in minimizing the chance of freezing in colder months, which could damage components.

4. COMPONENT CLEANING AND INSPECTION

After draining, a meticulous examination and cleansing of all components is essential. Certain elements, particularly the filter screens and impellers, can accumulate dirt, algae, or mineral deposits that interfere with functionality. Ensuring that these parts are clean contributes significantly to pump performance.

A gentle cleaning solution, combined with a soft brush, is often sufficient to remove stubborn deposits without causing damage. After thorough cleaning, rinse the components with fresh water, ensuring no cleaning agents are left behind. Following this, inspect the parts for any signs of wear or damage that might necessitate replacement.

Another crucial aspect of the inspection process is to evaluate the solar panels for any obstructions that may impact efficiency. This could include environmental debris or damage from weather conditions. Keeping these surfaces clear is essential for optimal sunlight absorption. Ensuring both cleanliness and integrity of components will ultimately enhance the reliability and effectiveness of the system.

5. MONITORING AND MINIMIZING BLOCKAGES

Monitoring the system for potential blockages is a continuous process that requires diligence. Blockages can arise from various sources, including accumulated debris, mineral deposits, or biological growths within pipes and pumps. Routine inspections should be scheduled to mitigate such issues before they escalate.

Implementing a preventative maintenance routine is a powerful strategy. This can include the use of sediment filters or screens to trap unwanted particles before they enter the pump. If using a filter, make regular checks and replacement part of the maintenance schedule, ensuring optimal flow and efficiency.

In instances where blockages are discovered, swift action is required. This may involve cleaning or removing certain components for thorough checks and repairs. Regular attention to these factors not only extends the life of the pump but also ensures optimal water flow, critical for operational success.

6. SOLAR PANEL MAINTENANCE

Solar panels are the heart of any solar automatic pump system, and thus their maintenance demands attention. Understanding the intricacies of solar panel upkeep can drastically affect the performance of an entire pumping system. Regularly cleaning the panels ensures they can absorb maximum sunlight, enhancing efficiency and output.

The primary concern for solar panel maintenance revolves around the accumulation of dust and debris. For optimal performance, panels should be wiped down with a damp cloth or hose to eliminate any obstructions to sunlight. In regions where bird droppings or other natural debris are common, more frequent cleanings may be required. Moreover, panels should be examined periodically for cracks or physical damage that could impact performance.

Enhancing the solar panels’ angle is another important consideration; optimizing the angle according to seasonal variations can significantly improve solar energy capture. Careful analysis of local weather patterns can inform the best positioning for panels throughout the year. Adjusting angles based on seasonal shifts will allow for more sunlight regardless of weather conditions.

7. ADDRESSING CLIMATIC INFLUENCES

Climatic conditions can have significant effects on the efficiency of solar automatic pumps, necessitating different approaches depending on regional variations. Understanding how temperature, humidity, and precipitation influence performance is crucial for effective maintenance.

In colder climates, ensuring proper drainage becomes vital to prevent freezing, which can compromise the integrity of mechanical seals and other components. Insulating vulnerable parts may provide additional protection against freezing temperatures. Conversely, hot climates may challenge the solar panels’ ability to operate efficiently. Regular checks on solar panel temperaturational regulations can aid in safeguarding the system from overheating.

Rain can wash away debris and dirt, yet excessive moisture can also lead to rust or corrosion of exposed metal components. Adequate drainage and consistent inspections will thus provide an effective barrier against potential damage.

Furthermore, a proactive strategy regarding weather forecasts can mitigate issues posed by unforeseen climate changes. Incorporating adjustable setups can further lend flexibility to the system, enhancing the pumping system’s ability to withstand diverse environmental factors.

8. ENSURING PROPER FUNCTION OF EQUIPMENT

For effective solar pump operation, a comprehensive approach to equipment functionality is imperative. Conducting thorough testing after maintenance and exhaustion processes guarantees all components respond as required. This involves checking the pump’s operational functionalities, solar panel efficiency, and power connections.

Solar energy conversion rates should be monitored closely to detect any dips in performance. Tracking energy output will highlight any discrepancies with expected outcomes. Likewise, examining pump output helps identify whether water flow meets requirements. Any signs of reduced performance should prompt an immediate review of the entire system architecture.

Regularly monitoring the operational metrics enables faster responses to issues, enhancing overall reliability. Establishing a set protocol for continuous checks can streamline this process, ensuring the system remains responsive to any maintenance needs.

9. PLANNING FOR EMERGENCIES

Being prepared for emergencies, such as sudden weather changes or component failures, is an essential aspect of solar automatic pump management. Strategic forward-thinking can prevent downtime and reduce losses associated with system failures.

One effective strategy is to maintain spare parts and tools on hand, ensuring swift repairs can occur without delays. Establishing relationships with suppliers guarantees prompt access to components when needed. Furthermore, documenting maintenance processes assists in identifying recurrent issues, streamlining preventive measures, and improving effectiveness.

Training personnel on proper emergency response procedures is equally critical. Ensure team members understand how to isolate faulty components safely and effectively while adhering to operational protocols. Regular drills can instill confidence and preparedness in managing unexpected situations.

10. INTEGRATING TECHNOLOGY FOR IMPROVED MONITORING

Modern technology can play a pivotal role in the management of solar automatic pumps. Implementing smart monitoring systems allows for real-time data collection and analysis, leading to better-informed decisions regarding maintenance and performance evaluations.

Numerous technological solutions are available, from mobile apps that monitor solar panel output to comprehensive software systems that analyze the entire pump’s performance. By incorporating these tools, operators can access vital statistics, helping to identify trends and deviations before they become significant issues.

Furthermore, these technologies can provide alerts for irregularities, prompting immediate attention to potential problems. Integrating advanced monitoring tools ensures that each element operates at its best, ultimately prolonging the lifespan and efficiency of solar automatic pump systems.

FAQS

WHAT ARE THE SIGNS THAT A SOLAR AUTOMATIC PUMP NEEDS MAINTENANCE?

Identifying maintenance needs in solar automatic pumps can often be detected through specific signs. One common indicator is a decrease in flow rate, which suggests potential blockages or inefficiencies within the system. Additionally, noises outside the normal operational sounds may signal mechanical issues that require attention. Another crucial sign to look for involves fluctuations in solar panel performance; if panels are not generating expected outputs, maintenance may be necessary. Finally, visible wear and tear on components, rusting, or excessive dirt accumulation are warning signs indicating the need for immediate servicing. Regularly monitoring all aspects of the system will ensure timely interventions, preventing further complications.

HOW OFTEN SHOULD A SOLAR AUTOMATIC PUMP BE EXHAUSTED?

The frequency of exhausting a solar automatic pump largely depends on various factors, including environmental conditions and the system’s specific usage. Generally, it is advisable to perform this action at the end of each operational season or before periods of extreme weather, such as heavy rain or freezing temps. Additionally, if the pump is used regularly or in regions with frequent dust storms, more regular exhaustion may be necessary to maintain efficiency and prevent blockages. Keeping track of the operational schedule and environmental impact will help dictate when exhaustion should occur. Set a clear maintenance schedule based on these observations to ensure comprehensive care and optimal pump performance.

WHAT ARE THE ADVANTAGES OF USING SOLAR AUTOMATIC PUMPS?

Embracing solar automatic pumps presents a multitude of advantages worth considering. Foremost is the cost-effectiveness—while the initial setup may be more substantial than traditional methods, the ongoing costs associated with solar energy drastically reduce long-term expenses. Additionally, their reliance on renewable energy sources contributes to environmental sustainability, significantly decreasing carbon footprints. The independence from fossil fuels offers users enhanced stability, especially in remote areas where access to traditional power sources may be limited. Finally, solar automatic pumps are known for their minimal maintenance requirements compared to conventional pumps, making them attractive for both residential and agricultural applications. Implementing this technology guarantees both ecological benefits and improved economic viability in the long run.

Ensuring efficient operation and longevity of solar automatic pumps requires comprehensive knowledge of their maintenance needs. By diligently performing the necessary steps for draining, cleaning, monitoring, and addressing potential challenges, one can greatly enhance the overall performance of these systems. In doing so, operators can enjoy reduced costs, improved efficiency, and a sustainable approach to water management. Understanding environmental conditions further contextualizes the significance of maintenance efforts, allowing users to adapt their strategies as needed. By employing technology, supporting proactive maintenance strategies, and training staff, users can cultivate reliability in solar pumping systems, guaranteeing that they remain operationally efficient throughout their lifespan. Ultimately, the commitment to thorough upkeep not only ensures the functional success of solar automatic pumps but also contributes positively to both economic and ecological sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-exhaust-the-solar-automatic-pump/