1. To successfully create a DIY solar aluminum plastic tube, several crucial steps are involved: 1. Selecting the right materials for construction, 2. Assembling the components appropriately, 3. Understanding the function and interaction of solar energy, 4. Testing and verifying the efficiency of the final product. One of the fundamental aspects revolves around the choice of materials; utilizing durable and lightweight items such as aluminum and specialized plastic is essential. The effectiveness of the tube is significantly influenced by its ability to capture and harness solar energy.

1. UNDERSTANDING THE PRINCIPLES OF SOLAR ENERGY

The utilization of solar energy has gained immense popularity due to its sustainability and accessibility. Comprehending the underlying principles that govern solar energy is vital for anyone looking to construct a DIY solar aluminum plastic tube. Solar energy is derived from sunlight, transformed into usable energy through photovoltaic cells or thermal collectors. These technologies capitalize on the sun’s radiation, translating it into heat and electricity usable for a variety of applications. In this context, understanding how these processes operate provides a foundational knowledge for the construction and application of a solar tube.

The core idea behind a solar aluminum plastic tube is to harness solar energy effectively. The design typically employs reflective materials that amplify sunlight directionally toward a thermal core, which can absorb and store heat. This interaction between sunlight and the reflective surfaces creates high temperatures, allowing for various applications, including heating water or generating electrical power. This basic principle underlines how solar energy can be captured, stored, and used efficiently through well-considered engineering and material choices.

2. MATERIAL SELECTION FOR CONSTRUCTION

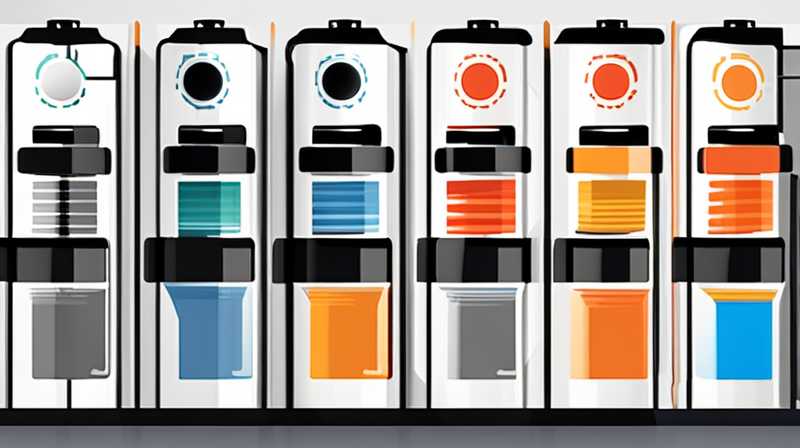

The choice of materials significantly influences the durability and efficiency of a solar aluminum plastic tube. Ideal components should offer both thermal efficiency and weather resistance. Aluminum, known for its lightweight and high reflective capabilities, serves as an excellent material for the outer structure of the tube. Its ability to resist corrosion further ensures longevity, making it suitable for outdoor applications subject to varying climatic conditions. Additionally, ensuring that the aluminum has adequate thickness will improve the overall performance of the tube.

On the other hand, selecting the right type of plastic is equally important. High-density polyethylene (HDPE) or polycarbonate are popular choices due to their strength and ultraviolet (UV) resistance. These materials not only provide excellent insulation but also protect the inner workings of the solar tube from harsh weather elements. Using a combination of aluminum for reflectivity and a robust plastic for insulation can create a highly efficient structure that efficiently captures and retains solar energy.

3. DESIGN AND ASSEMBLY PROCESS

Creating an effective DIY solar aluminum plastic tube requires a carefully planned design. The initial step involves creating a sketch of the intended design, ensuring proper dimensions that provide enough surface area for solar absorption. The design should also account for the placement of the tubular structure to maximize sunlight exposure throughout the day. It is essential to position the solar tube in a location free from obstructions like trees or buildings that could cast shadows during sunlight hours.

When assembling the tube, begin by cutting the aluminum sheets to the predetermined sizes. The sheets should be bent to form a cylindrical shape, ensuring that joints are securely fastened to maintain structural integrity. Utilizing rivets or screws ensures that the components stay firmly in place. Once the aluminum exterior is constructed, proceed to insert the insulating plastic liner. This liner will not only provide insulation but will also serve as a protective barrier against potential damage. Proper aligning and sealing of the components is critical at this stage to prevent any loss of heat or engagement of moisture.

4. FUNCTIONS OF THE SOLAR TUBE

The efficacy of a DIY solar aluminum plastic tube heavily relies on its functionality. Depending on the design specifications, the constructed tube can serve various purposes, from simple water heating solutions to more complex electrical applications. When applied in water heating systems, these tubes can siphon sunlight directed to a metal container filled with water, raising the water temperature during sunlight exposure. Success in achieving high temperatures requires ensuring minimal thermal loss, which can be accomplished with effective insulation around the tube.

Moreover, for applications involving electricity generation, the integration of photovoltaic panels with the solar tube can convert solar energy directly into electrical energy. This dual-functional approach not only expands the utility of a DIY solar tube but also enhances its efficiency. Understanding the various applications of the constructed tube allows users to innovate and customize according to their specific energy needs. Regular monitoring of performance helps in timely identification of inefficiencies or necessary adjustments.

5. TESTING AND MONITORING PERFORMANCE

After constructing the solar aluminum plastic tube, evaluating its efficacy is a crucial next step. Testing can include multiple factors, such as temperature measurements, overall heat retention and energy throughput. Using thermometers or infrared sensors can provide insights into how well the tube is performing under direct sunlight. By assessing the water temperature at regular intervals, users can gain valuable data on whether alterations are needed in terms of insulation or placement to maximize exposure.

Continual monitoring of performance is essential to maintain efficiency over time. Seasonal variations impact the exact positioning and usage, hence an adaptable approach should be promoted. Users might need to modify the angles of the tube or adjust settings based on the sun’s trajectory across the seasons. Furthermore, ensuring that the reflective surfaces are clean and free of debris will maintain optimal performance. Regular maintenance and performance checks can lead to long-lasting benefits and higher returns on investment for the constructed solar tube.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IMPORTANCE OF INSULATION IN A SOLAR TUBE?

The role of insulation in a solar tube cannot be overstated. This component significantly affects the tube’s overall efficiency by minimizing heat losses to the environment. Effective insulation materials, such as high-density polyethylene or similar, ensure that temperatures within the tube are retained for heating purposes without significant leakage. Furthermore, insulation also serves to protect internal components from external weather conditions, contributing to longevity and durability. Hence, employing adequate insulating materials is critical when constructing a solar aluminum plastic tube, as it directly correlates with overall energy efficiency.

HOW MUCH SUNLIGHT DOES A SOLAR TUBE NEED TO WORK EFFECTIVELY?

The amount of sunlight required for optimal performance of a solar tube varies considerably depending on several factors, including geographic location, tube orientation, and the specific application for which it is used. Generally, direct sunlight exposure is vital to achieve high temperatures quickly. Ideally, positioning the tube in an unobstructed area with a clear southern exposure (in the Northern Hemisphere) will yield the best results. Although some energy can be generated in overcast conditions, the efficiency is significantly reduced. Overall, ensuring maximum sunlight exposure will enhance performance and effectiveness.

CAN A DIY SOLAR TUBE BE USED FOR HEATING SPACES?

Indeed, a DIY solar aluminum plastic tube can be adapted for space heating. By circulating air through the heated tube, the warmed air can be directed into living spaces. This can be achieved through a fan system, enabling movement of heated air into designated areas. However, careful design considerations should be made regarding airflow rates and overall system efficiency to ensure that energy costs do not offset the benefits gained from the solar heating process. Implementing such systems can lead to substantial energy savings, thus enhancing the utility of the constructed solar tube.

To encapsulate, constructing a DIY solar aluminum plastic tube involves careful planning and execution to harness solar energy effectively. Not only is material choice vital, but also the design and function must be thoroughly considered. Ensuring proper insulation plays a pivotal role in optimizing thermal retention, while positioning the tube to achieve maximum sunlight exposure is essential for efficiency. As such, engaging in thoughtful construction and continuous monitoring can lead to notable energy savings and reduced utility costs for users. The adoption of solar technology such as this not only benefits individual households but significantly contributes to broader environmental sustainability goals. As the global shift towards renewable energy escalates, understanding and utilizing such innovations is crucial. Engaging in the creation of a solar tube can serve as an educational journey, further promoting the importance of renewable resources and energy efficiency in contemporary society. Through practical knowledge and application, a DIY solar aluminum plastic tube can effectively support green initiatives while catering to personal energy needs, showcasing the potential of individual contributions to collective environmental wellbeing.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-diy-solar-aluminum-plastic-tube/