To dissolve silicone in solar lamps, there are several effective methods that can be employed. 1. Understanding the nature of silicone is essential for selecting the right dissolving agent, 2. Utilizing solvents such as isopropyl alcohol or acetone can help break down the silicone material, 3. Mechanical methods, like scraping or heating, might also be effective when combined with chemical agents, 4. Safety precautions must be maintained while handling chemicals. The most effective approach involves the use of appropriate solvents, which require careful consideration of the materials involved and necessary safety measures when working with potentially harmful substances.

UNDERSTANDING SILICONE IN SOLAR LAMPS

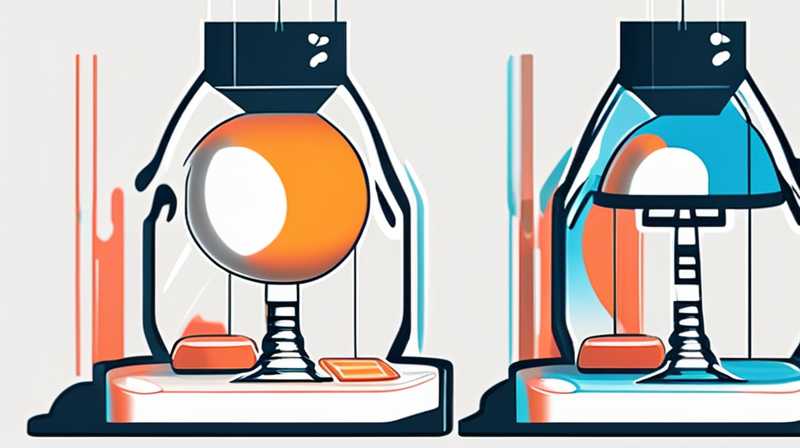

Silicone serves as a pivotal material in the assembly of solar lamps, prominently due to its excellent adhesive properties and durability. This synthetic polymer is renowned for its resistance to weather conditions, ultraviolet radiation, and temperature fluctuations, which makes it an ideal candidate for outdoor applications. However, there may arise instances when the silicone sealant needs to be removed, either for repair purposes or replacement of components. This scenario necessitates a deep understanding of silicone’s chemical properties and the challenges associated with dissolving it.

The challenge arises from silicone’s chemical stability and molecular structure, making it resistant to many common solvents. In particular, typical household cleaners are ineffective against silicone adhesives, which can lead to complications when attempting to disassemble solar lamps for maintenance or repair. Understanding silicone’s resilience is fundamental in choosing the right approach to dissolve it, and selecting the most effective solvent will ultimately lead to successful removal without causing damage to the surrounding components.

CHOOSING THE RIGHT SOLVENT

1. Types of solvents: Isopropyl Alcohol and Acetone.

When it comes to selecting the correct solvent for dissolving silicone, two prominent options stand out: isopropyl alcohol and acetone. Isopropyl alcohol is a common solvent that effectively breaks down adhesive materials while providing a relatively safe option for household use, whereas acetone, known for its powerful solvent properties, can aggressively dissolve silicone but may also pose risks to certain plastics and paint finishes. Each solvent has its advantages and potential drawbacks, making it imperative to consider the specific characteristics of the model of the solar lamp in question.

Isopropyl alcohol, often available in concentrations ranging from 70% to 99%, is efficient in breaking down silicone without causing significant harm to many materials. This property makes it an ideal choice for various applications, including delicate repairs. On the other hand, acetone, a much stronger solvent, can expedite the removal process of stubborn silicone but requires caution, particularly with sensitive materials or finishes that may be adversely affected. Cleaning up after has never been easier, but ensuring compatibility with the solar lamp’s materials can prevent unintended damage.

2. Other solvents and removal agents.

Besides isopropyl alcohol and acetone, several other solvents can prove beneficial for dissolving silicone in solar lamps. For instance, silicone removers specifically formulated to break down sealants can be sought, as they often contain chemical compounds designed to target silicone bonds effectively. These commercially available products may simplify the process substantially, but caution should be exercised to verify compatibility with the lamp’s materials before use.

Moreover, alternative natural solvents such as vinegar or citrus-based cleaners may be attempted, although their effectiveness may vary and often depend on the thickness and type of silicone used. Evaluating each alternative based on potential risks, effectiveness, and the specific structure of the solar lamp can provide informed choices in this endeavor. Engaging in trials with small amounts of any chosen solvent will ensure results before applying to larger areas.

MECHANICAL METHODS

1. Scraping Techniques.

In addition to solvents, mechanical methods can assist in the removal of silicone. A scraping tool, such as a utility knife or a thin blade, can carefully remove the silicone from the edges of the solar lamp without damaging the underlying material. It is essential to maintain a steady hand and work delicately to ensure that the surface of the lamp is not scratched or compromised during this process. This technique proves effective, especially when combined with solvents that have had time to soften the silicone.

Before utilizing any scraping techniques, it is crucial to allow the selected solvent ample time to penetrate the silicone. This delay allows the solvent to work effectively, resulting in silicone that is easier to lift and remove. While scraping may be labor-intensive, it is often necessary to ensure that all remnants of silicone are successfully extracted, preventing any obstruction in the operational components of the solar lamp.

2. Heating Techniques.

Another mechanical method involves the application of heat to soften silicone for easier removal. Using a heat gun or a hairdryer can gently raise the temperature of the silicone, causing it to become pliable. Once warmed, silicone can often be scraped away more efficiently. It is important, however, to control the heat applied, as excessive temperatures can risk damaging the surrounding materials or electronic components.

This technique should be used judiciously, ensuring that any heat applications are focused and not prolonged. Implementing heat, particularly in conjunction with a good solvent, can increase overall effectiveness and make the laborious task of removal much more manageable. Monitoring the situation ensures that melting of plastics or overheating of components does not take place.

SAFETY CONSIDERATIONS

1. Personal Protective Equipment (PPE).

While attempting to remove silicone from solar lamps, safety precautions must be addressed seriously. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and masks will protect against harmful chemical exposure from solvents. Though products like isopropyl alcohol may seem benign, prolonged exposure can cause skin irritation, while stronger solvents such as acetone can lead to respiratory disturbances if fumes are inhaled. Safety equipment safeguards against these risks and enables a safer working environment.

Contemplating adequate ventilation is also of significant concern. Working outside or in a well-ventilated area significantly reduces inhalation risks associated with fumes produced by solvents. Ensuring airflow can make the process less hazardous, fostering an atmosphere conducive to effective and safe silicone removal.

2. Material Compatibility and Testing.

Prior to utilizing any dissolving agent, testing a small, inconspicuous area of the solar lamp is advisable. This testing is necessary to gauge potential reactions and avoid damage to the lamp’s finish or structure. Some materials specifically react adversely to strong solvents, leading to discoloration or degradation. Identifying precise compatibility with materials like plastic, glass, or metals can enhance the efficiency of this process without risking long-term cosmetic harm.

This step of caution in testing can save a great deal of future inconvenience, allowing for adjustments to be made ahead of more extensive efforts, should any negative reactions be noted. Assessing fluid interaction provides a wise pathway toward successful silicone removal during any repair endeavor.

MAINTAINING YOUR SOLAR LAMP POST REMOVAL

1. Cleaning Surfaces.

After the silicone is successfully removed, thorough cleaning of the surfaces is essential. Residual solvent or silicone remnants can hinder the functionality of the lamp or affect the adherence of new materials if repairs or replacements are planned. Using a soft cloth dampened with a gentle cleaning solution can help remove any lingering traces from previous attempts.

After cleaning, allowing the surface ample time to dry and air out is advantageous. This practice mitigates the risk of applying new adhesives to a still moist environment, ensuring that all elements adhere effectively and securely during reassembly. By maintaining cleanliness and vigilance, any subsequent repairs can be executed with a guarantee of solidity and efficacy.

2. Preventive Measures for the Future.

To prolong the life of the solar lamp and reduce the chances of silicone issues arising again, consider routine maintenance practices. Checking seals for wear and tear regularly can help identify potential problems before they escalate further. Additionally, using high-quality silicone products that are explicitly designed for outdoor use can enhance resilience against weather interference.

Being proactive involves routine inspections to confirm that no moisture has penetrated areas where it should not exist. Adopting these preventive measures can create a sustainable operating environment and lessen the likelihood of future concerns regarding silicone adhesion in solar lamps.

COMMON INQUIRIES

HOW LONG DOES IT TAKE FOR SOLVENTS TO DISSOLVE SILICONE?

The duration for solvents to dissolve silicone can vary significantly based on multiple factors, including the thickness of the silicone layer, the specific solvent being used, and environmental conditions like temperature and airflow. Typically, one should allow the solvent to sit on the silicone for a duration of 10 to 30 minutes before attempting to remove it with a scraper or cloth. Thicker layers of silicone may necessitate longer times or multiple applications of solvent. It is vital to observe the progress and adjust accordingly, ensuring that the silicone has adequately softened without compromising the surrounding materials.

In many scenarios, patience plays a crucial role in achieving the desired outcome, as rushing the process may lead to damaged components or incomplete removal. Testing the effectiveness continuously throughout this duration will provide insights that foster an informed approach, resulting in successful silicone removal.

CAN I USE HOUSEHOLD PRODUCTS LIKE VINEGAR TO DISSOLVE SILICONE?

While vinegar is a common household product known for its cleaning abilities, it is generally less effective than specialty solvents like isopropyl alcohol or acetone for dissolving silicone. The acidity in vinegar may have minimal impact on softer silicone sealants but is unlikely to produce satisfactory results for hardened or thickly applied silicone adhesive.

If opting to use vinegar, one must be cautious and realistic about its capacity to dissolve the silicone completely. It may serve as a supplementary measure after utilizing more effective solvents or as an initial cleaner before further attempts. Experimentation can yield various results, but understanding the limitations is essential for ensuring proper expectations throughout the process.

IS IT SAFE TO REMOVE SILICONE FROM OUTDOOR SOLAR LAMPS?

Removing silicone from outdoor solar lamps can be executed safely with the correct methods and precautions in place. Using PPE, ensuring adequate ventilation, and testing solvents on small hidden areas can mitigate risks associated with chemical exposures and reactions. Thus, as long as safety measures are observed, the process can be conducted effectively without compromising personal health or the integrity of the fixture itself.

That being said, the application of heating methods, the aggressive use of solvents, and actions leading to potential fragmentation of materials should be closely monitored. By adhering to guidelines and selecting methods suited for the condition of the lamp, one can confidently remove silicone while maintaining a focus on personal and environmental safety.

In summary, dissolving silicone from solar lamps necessitates a well-planned strategy, leveraging appropriate chemicals and methods to ensure optimal results. Understanding the interaction between different solvents and the materials involved remains crucial in this process. Safety protocols must always be upheld, so employing personal protective equipment and testing solvent compatibility is recommended. Through diligence and care, removal of silicone can be accomplished, allowing for successful maintenance, repairs or reassembly of solar lamps. Engaging in proper cleaning methods post-removal will further enhance the longevity, ensuring operational safety and efficiency for outdoor lighting solutions. Adopting preventive measures will also mitigate future silicone-related issues, enhancing the functionality of your solar lamps over time, and maintaining them in great condition.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dissolve-silicone-in-solar-lamps/