To dismantle a solar tube effectively, begin with the appropriate tools and safety precautions. 1. Gather essential tools, 2. Ensure safety measures, 3. Understand the solar tube structure, 4. Carefully remove the components. Start by collecting necessary tools such as screwdrivers, pliers, and gloves for protection. It’s crucial to wear safety goggles to shield your eyes from debris. Each solar tube comprises several parts, like the outer tube, the vacuum layer, and the internal reflector. Understanding this will facilitate a smoother dismantling process.

Once you’ve ensured safety, focus on each component individually while paying attention to the assembly instructions or diagrams if available. This careful, methodical approach not only assists in dismantling but also aids in future reassembly if needed. Always keep track of screws and small components throughout the process. Being meticulous during dismantling ensures that no parts are damaged or lost, which can prevent complications later on.

1. TOOLS REQUIRED FOR DISMANTLING

Dismantling a solar tube necessitates specific implements that enhance efficiency. Important tools include screwdrivers, wrenches, safety goggles, and gloves. Utilizing the appropriate screwdriver is essential as it ensures a perfect fit for screws, reducing the likelihood of stripping them. A range of screwdriver heads such as Phillips and flathead may be required depending on the type of fasteners used in the assembly of the solar tube.

Wrenches become necessary when handling larger bolts that secure the solar tube to its base. Selecting the right size is crucial to avoid rounding the edges and compromising the hardware. Safety goggles protect against debris that may come loose during disassembly. Gloves are equally important, safeguarding hands from potential cuts or scrapes incurred from sharp edges. Failing to have the right tools can lead to frustration, prolonging the dismantling process.

2. SAFETY MEASURES

Prioritizing safety is indispensable when tackling a project involving solar tube dismantling. Ensuring safety involves proper attire and workspace preparation. Wearing durable work gloves will shield hands from accidental injuries while handling metal components. Sturdy footwear prevents foot injuries if tools or parts fall during the operation. Additionally, using personal protective equipment such as eye protection prevents exposure to harmful debris.

Proper workspace organization is also integral to safety. A clean, well-lit area reduces the risk of tripping over tools or parts, allowing for a more focused workflow. Clear away unnecessary obstacles to maintain a secure environment. Furthermore, when working on ladders or elevated surfaces, it’s important to maintain three points of contact to avoid falls. Dedicating attention to safety vastly diminishes the risk of accidents and promotes a day of productive work.

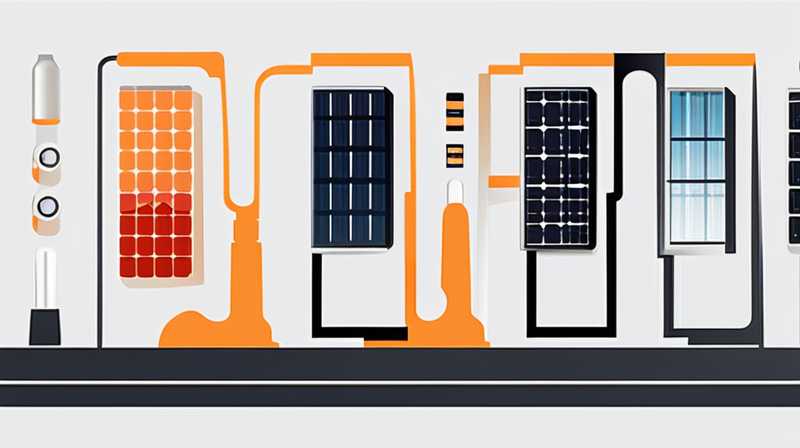

3. UNDERSTANDING THE STRUCTURE OF A SOLAR TUBE

Gaining insight into the components of a solar tube is essential prior to dismantling. Typically, a solar tube consists of an outer protective shell, an internal vacuum layer, and an inner reflective surface. The outer shell serves as a barrier against environmental elements, while the vacuum space aids in heat retention. This system allows for maximum insulation, hence enhancing energy efficiency.

The reflective surface plays a pivotal role in directing sunlight towards the collection area, maximizing solar gain. Knowledge of each part’s function and location can significantly expedite the dismantling process. Understanding how these components interconnect avoids rapid disassembly that could result in damaged parts, particularly the fragile vacuum layer. Identifying possible attachment points is crucial as it directs attention during the initial phase of dismantling.

4. REMOVING COMPONENTS STEP-BY-STEP

Dismantling a solar tube involves a systematic approach to each component. Begin with the outer casing, moving toward the inner vacuum and reflective layers. Start by unscrewing or unclipping the outer casing from its fixed position. It may be necessary to employ moderate force when detaching components that have become sealed over time due to environmental conditions. Using the correct tools minimizes the risk of damaging surrounding areas.

Once the outer casing is removed, carefully expose the vacuum layer. Advanced attention is crucial here, as the vacuum is sensitive to structural integrity. If the vacuum is compromised during disassembly, it impacts the energy efficiency of the solar tube. Using a gentle twisting motion can facilitate the separation of both layers. Finally, isolate the reflective surface, which often is held in place with clips or additional screws. Following this step-by-step strategy aids in a smooth dismantling process.

5. POTENTIAL CHALLENGES DURING DISASSEMBLY

During the dismantling process, certain challenges may arise. Common issues include corroded screws, stubborn components, and unexpected structural damage. Corroded screws can be a frustrating hindrance; often, they require specialized removers or techniques to extract. Applying penetrating oil can assist in loosening rusted or stuck screws, providing a better chance at avoiding snapping off screw heads.

Stubborn components may also resist separation, particularly if adhesives were used during installation. Utilizing plastic scrapers can facilitate gentle prying without damaging the underlying structure. If any parts appear unexpectedly damaged or worn, it’s vital to reassess previous cleaning or environmental conditions that may have led to degradation. Addressing these challenges early can significantly mitigate delays and promote a successful dismantling operation.

FAQs

WHAT IS A SOLAR TUBE?

Solar tubes, often referred to as solar tube collectors, are cylindrical devices designed to harness solar energy. They function by allowing sunlight to enter the tube and transform it into heat, which can be utilized for various applications such as heating water or home interiors. Comprised of a vacuum-sealed layer that minimizes heat loss and a reflective coating that enhances light absorption, solar tubes exhibit remarkable efficiency in capturing solar radiation. Typically installed on rooftops, these tubes are favored for their compact size and ability to perform efficiently even in overcast conditions. Understanding their mechanics can help to appreciate their contribution to sustainable energy.

HOW LONG DOES IT TAKE TO DISMANTLE A SOLAR TUBE?

Dismantling a solar tube can vary significantly in terms of time investment due to several factors. Generally, the process can take anywhere from one to three hours. Factors influencing the duration include the complexity of the installation, the presence of corrosion on screws, and the individual’s experience in handling such tasks. Individuals familiar with basic construction or plumbing techniques may progress more swiftly, while novices may face learning curves requiring additional time for comprehension. Preparing adequately with the right tools and a clear understanding of the system can facilitate a more efficient dismantling process.

CAN I REASSEMBLE THE SOLAR TUBE AFTER DISMANTLING?

Yes, it is entirely possible to reassemble a solar tube following proper dismantlement procedures. Careful organization of components during disassembly is essential to facilitate straightforward reassembly. Keeping track of screws and parts ensures that nothing is lost or misplaced. Additionally, thorough inspection of each component for wear or damage is essential before reassembly, as it can assist in pinpointing necessary replacements. It’s also advisable to refer to original installation guides or diagrams to ensure proper orientation of parts during reassembly. With attention to detail and systematic handling, successful reassembly can be achieved.

The ability to dismantle a solar tube requires methodical planning and execution. Understanding tools and safety measures are vital aspects of the process. Awareness of the solar tube’s structure enriches insight, guiding a smoother dismantling experience. Each component’s careful removal ensures that operational efficiency is maintained for potential reinstallation. Addressing possible challenges proactively can prevent significant setbacks. Ultimately, the approach taken during dismantling underlines the value of this project for sustainability. This knowledge empowers individuals to maximize the benefits of solar energy systems effectively, supporting both personal needs and broader ecological goals.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-tube-2/