To effectively dismantle a solar stop valve, one needs to follow a systematic approach. 1. Understand the purpose and function of the solar stop valve, 2. Gather necessary tools and safety equipment, 3. Follow proper disassembly steps, 4. Ensure all components are inspected before reassembly. The solar stop valve plays a crucial role in regulating fluid flow within solar thermal systems, ensuring optimal performance. Known as a necessary component, it helps prevent backflow and maintains system efficiency. Familiarity with its mechanism and parts is imperative before attempting any disassembly, ensuring safety and effectiveness during the process.

- UNDERSTANDING THE SOLAR STOP VALVE

A solar stop valve is essential in solar thermal energy systems, serving a pivotal role in managing fluid circulation. Often installed within the system to facilitate the regulation of high-temperature fluids, this device reliably prevents unwanted backflow that could compromise efficiency. The primary purpose of the solar stop valve is to ensure proper fluid dynamics within the solar heating system. This includes defining the direction of flow, which is critical for salvaging the efficiency of solar collectors and enhancing their functionality.

One notable characteristic of the solar stop valve is its thermal resilience. Designed specifically for high-temperature applications, these valves are built to withstand the unique challenges presented by solar heating systems. Many stop valves employ materials that resist thermal expansion and contraction, ensuring longevity and reliability. Therefore, an understanding of the valve’s design is essential for a tailored approach to dismantling it.

- TOOLS AND SAFETY PREPARATION

Before diving into dismantling the solar stop valve, accruing the necessary tools cannot be overemphasized. Essential tools include a wrench, screwdriver, safety goggles, gloves, and a bucket or basin to catch any fluid during the process. Each tool serves a unique function; for instance, the wrench allows for loosening and tightening threaded parts, whereas screwdrivers help in removing screws or securing components.

Equally important is adopting safety precautions to mitigate potential hazards. Solar thermal systems can retain hot fluids even when disconnected from operational energy inputs. As a result, wearing safety goggles and heat-resistant gloves becomes paramount. These items protect the technician from splashes and spills, as heated liquid can lead to burns or injuries.

Preparing the workspace prior to the operation also contributes significantly to safety. A clutter-free area prevents accidents or misplaced tools, and having a designated spot for removed components fosters organization. This preparation builds a solid foundation for an efficient dismantling process.

- DISASSEMBLY PROCESS

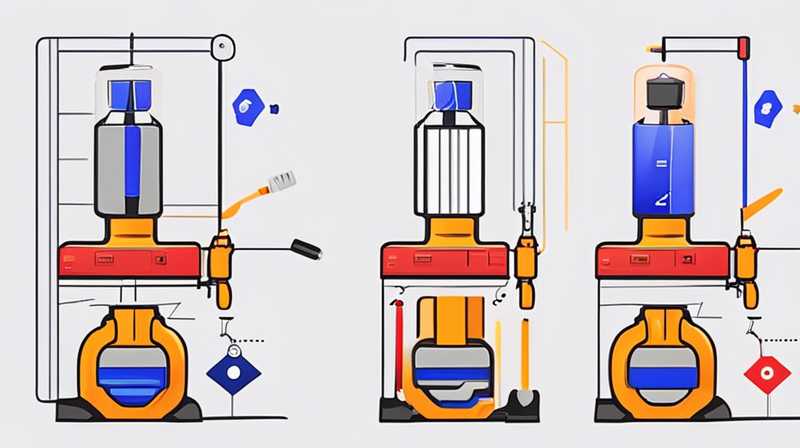

The disassembly of a solar stop valve mandates a methodical approach, aimed at preserving component integrity for potential reassembly. Begin by turning off any connected power source and closing the valves on either side of the stop valve. Allowing the system to cool entirely is critical, and this mitigates risks related to high-temperature fluids.

Once the system is safely powered down and cooled, the next step involves removing the valve from its mounting. Utilize the wrench to undo screws or bolts securing the valve in place. Apply ample force but be cognizant of over-tightening, which might warp housing materials. It is crucial to maintain hold of screws and any other minor components removed to prevent loss during the process.

After detaching the valve from its location, the next phase consists of disconnecting the fluid piping. Depending on the brackets or clamps used, you may need to carefully unfasten these components, ensuring not to damage the piping materials. Place a bucket or basin underneath to collect any residual fluid. This methodical approach not only protects the environment but also keeps the workspace tidy.

- COMPONENT INSPECTION AND REASSEMBLY PREPARATION

Once the solar stop valve is fully disassembled, attention should shift to inspecting each component for wear or damage. Common elements to evaluate include seals, ball mechanism, and the valve body itself. It’s essential to check for corrosion or scaling which might hinder the valve’s functionality in the future. A thorough cleaning of these components can enhance performance and extend the lifespan of the valve.

If any components exhibit damage or signs of degradation, replace them prior to reassembly. Using OEM parts ensures compatibility and reliability within the system. Having an array of replacement seals and springs on hand can facilitate a smoother restoration process.

When embarking on the reassembly, take care to reverse the steps taken during disassembly. Ensure that all components are correctly positioned, and tighten screws and clamps uniformly to prevent leaks. Consider engaging with repair guides or manuals specific to your valve’s manufacture when in doubt. This ensures restorations meet manufacturer specifications.

- MAINTENANCE SUGGESTIONS

Regular maintenance of a solar stop valve fosters longevity and system efficiency. Establish a routine that includes periodic inspections at least once a year. During these evaluations, confirm that no leaks develop around the valve and check the integrity of the seals or components. Addressing any small issues early can prevent larger failures down the line.

In addition, cleanliness is vital. Ensuring the valve and surrounding piping remain free of debris and buildup will enhance performance. Consider the incorporation of filtration systems to capture particulate matter before it enters the valve. Filter replacements should coincide with the established maintenance routine to uphold optimal flow within the system.

Proactive adjustments to temperature and pressure settings according to seasonal demands can also optimize valve function. Be mindful of fluctuating temperatures that may affect system operations. Employing temperature sensors may assist in gauging when manual interventions are needed.

Frequently Asked Questions

WHAT IS A SOLAR STOP VALVE?

A solar stop valve serves a critical function within solar energy systems by regulating fluid flow. Functioning as a one-way mechanism, it prevents backflow which could cause inefficiencies in heat exchangers or solar collectors. Solar thermal systems utilize high temperatures, thus these valves are engineered for resilience against thermal stresses. When malfunctioning, it can lead to system downtime and higher operational costs. Due diligence regarding its maintenance or timely replacement is essential to ensure the longevity and efficiency of solar power installations.

HOW OFTEN SHOULD A SOLAR STOP VALVE BE INSPECTED?

Routine checks should be conducted at least annually to maintain operational integrity. During such evaluations, inspect for leaks, corrosion, and the overall condition of seals and interior mechanisms. A proactive approach can preemptively identify potential malfunctions before they escalate into significant issues that might compromise solar thermal systems. Engaging qualified technicians during these inspections can bring light to areas that might require attention. Additionally, if systems experience regular fluctuations in pressure or temperature, inspections may need to occur more frequently, ideally aligning with seasonal changes to ensure optimal performance year-round.

CAN I DISMANTLE A SOLAR STOP VALVE MYSELF?

Yes, dismantling your solar stop valve independently is feasible, provided you have the requisite knowledge and tools. However, if you feel uncertain about any aspect of the process, consulting with a professional is highly advisable. Familiarization with system components— including valves— can significantly help ensure proper handling. Properly understand the dismantling process to guard against potential injury from hot fluids. Furthermore, incorrect reassemblies can lead to system inefficiencies or failures. Hence, always prioritize safety and comprehension when engaging with energy systems.

In summary, dismantling a solar stop valve necessitates a detailed understanding of both its purpose and function within the solar thermal system. Preparedness with an appropriate toolkit and safety measures is essential. Methodically undertaking the disassembly process ensures safe and effective operations. Inspections of the valve components post-disassembly allow for assessing any necessary replacements before reassembly. Implementing a maintenance routine creates longevity and efficiency in solar systems while underscoring the importance of regular checks and balances associated with solar energy management. Addressing each of these elements proficiently will not only contribute to the valve’s sustained performance but also solidify broader operational efficiencies in solar thermal installations across diverse environments.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-stop-valve/