To dismantle a solar solenoid valve network effectively, one must understand a few critical steps: 1. Preparation of proper tools and safety gear, 2. Systematic disconnection of electrical components, 3. Gradual removal of solenoid valves, 4. Proper disposal or recycling of unwanted components. The process begins with assembling the right tools, including wrenches, screwdrivers, pliers, and safety equipment like gloves and goggles to ensure personal safety. The next step involves carefully disconnecting the electrical components attached to the solenoid valves before proceeding to their physical removal. Each valve must be removed systematically to avoid damaging the remaining components of the network. Disposal should align with local regulations, particularly regarding electronic devices and metals, ensuring environmentally responsible practices. A comprehensive understanding of the solar solenoid valve network’s operation and configuration prior to engaging in dismantlement is crucial, ensuring all equipment and materials are handled delicately and appropriately to prevent unnecessary waste or hazards.

1. UNDERSTANDING THE SOLAR SOLENOID VALVE NETWORK

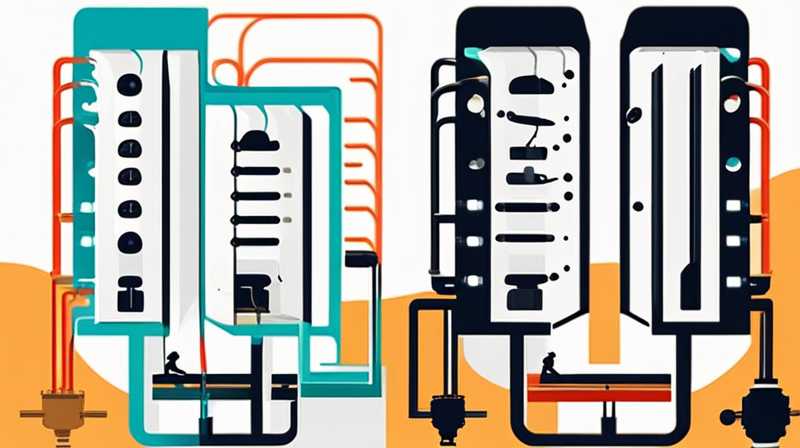

Examining the configuration and functionality of a solar solenoid valve network reveals an intricate system designed to optimize fluid flow management within solar water heating systems. Solar solenoid valves act as automatic switches that regulate the flow of heated water, allowing optimal transfer and storage of thermal energy. Understanding the fundamental mechanics of these valves involves comprehensive knowledge of hydraulic systems, electrical components, and the interplay between various devices within the solar energy paradigm.

Each component in this network plays a pivotal role in facilitating the flow of fluids, controlled by electrical signals from controllers. The solenoid valve itself comprises a coil that generates a magnetic field upon receiving power, thus activating the valve to either open or close. This opening and closing mechanism is crucial for managing the thermal energy flow, ensuring that water is circulated efficiently, heated adequately, and stored when necessary. Therefore, comprehensively grasping these fundamentals provides clarity on why dismantlement requires precision and thorough understanding.

2. TOOLS AND EQUIPMENT REQUIRED FOR DISMANTLING

Preparation is paramount when engaging in the dismantlement of a solar solenoid valve network. The right tools not only make the job easier but also mitigate the risks associated with improper handling of electrical and hydraulic systems. A toolkit well-stocked with various socket sets, wrenches, pliers, and wire cutters is essential for disassembling the intricate network without causing harm to the components involved.

In addition to hand tools, safety equipment plays a critical role in ensuring the individual dismantling the network remains unharmed. Personal protective gear such as safety goggles, gloves, and sturdy footwear cannot be overlooked. Incorporating these elements into the preparation phase creates an environment where risks are significantly minimized. Having the correct tools and safety gear at hand can streamline the entire process, making dismantlement efficient and safe.

3. SYSTEMATIC DISCONNECTION OF ELECTRICAL COMPONENTS

Chronological order matters significantly when disconnecting electrical components attached to the solenoid valves. Prior to any physical dismantlement, it is critical to power down the entire solar heating system, thus preventing any shock hazards or unintended activation. Identifying the main power source and ensuring it is entirely disconnected will eliminate risks during the disassembly phase.

Once the system is de-energized, begin tracing the wiring that connects all solenoid valves to their electrical signals. Taking the time to document how each component is connected is vital for future reference, particularly if reassembly or installation of a new system is intended. Labels might be attached to wires or drawings created to clarify connections and remain systematic in disconnection. A methodical approach ensures no components are overlooked or mishandled, ultimately preserving their condition for potential re-use or recycling.

4. REMOVING THE SOLENOID VALVES

The physical removal of solenoid valves from the network requires gentle handling to avoid damaging any connectors or surrounding structural components. With electrical components already disconnected, one can focus on the mechanical aspects of the solenoid valves. Each valve will typically be secured by screws or bolts, which can be removed meticulously using appropriate tools.

In cases where the valves are attached with additional fittings and pipes, it’s important to examine carefully for any signs of corrosion or wear that may complicate removal. If any resistance is encountered during the detachment process, employing penetrating oils or lubricants can assist in loosening stubborn components. Taking care while doing so reduces the likelihood of breakage, ensuring that the remaining material can be recycled or utilized effectively.

5. DISPOSAL OR RECYCLING OF COMPONENTS

Dealing with the components extracted from the solar solenoid valve network necessitates a responsible disposal approach. Local regulations concerning electrical waste should guide the disposal methods used, especially regarding the recycling of metals, plastic, and electronic parts. It is critical to segregate components into suitable categories to facilitate efficient recycling, thereby minimizing environmental impact.

Many regions have designated recycling facilities that accept electronic waste. Doing proper research to find these facilities not only adheres to regulatory standards but also promotes environmental sustainability. Proper recycling additionally enables the recovery of valuable materials, decreasing demand for new resources and ultimately aiding in the conservation of the planet’s ecosystems.

6. PREVENTIVE MEASURES FOR FUTURE INSTALLATIONS

To avoid the hassle of future dismantlement, implementing preventive measures during installation of solar solenoid valve networks can prove beneficial. Using clearly labeled wiring and connectors from the outset can significantly enhance ease of access in future maintenance tasks. Additionally, providing ample space around each solenoid valve facilitates better airflow and access for routine checks or replacements.

Regular inspections and maintenance practices can also prolong the life of the solenoid valves and the connected network. Scheduling routine assessments can detect potential issues before they escalate, ultimately preventing a situation where extensive dismantling becomes necessary. A commitment to proactive maintenance of solar components promotes efficiency and longevity, ensuring continued functionality and energy savings.

7. COMMON MISTAKES DURING DISMANTLEMENT

Dismantling a solar solenoid valve network presents its share of challenges, and novices may encounter typical pitfalls if not adequately prepared. One common mistake is neglecting to document connections and disconnections; forgetting how components are linked can lead to confusion when reassembling or setting up a new system. This highlights the need for careful notes or photographs as a means to keep track of the system’s configuration.

Another error involves hasty disconnection or removal of components, posing risks of physical damage or injury. A methodical approach cannot be emphasized enough; taking the time to ensure every connection is handled meticulously contributes to a smoother process. By avoiding these common mistakes, individuals can ensure a safer and more efficient dismantlement experience.

FAQs

WHAT ARE SOLENOID VALVES USED FOR IN SOLAR SYSTEMS?

Solar solenoid valves serve a significant purpose in solar heating systems, primarily for regulating the circulation of heated fluids. They allow for the automatic control of fluid flow based on various factors such as temperature and pressure. When the solar collector generates heat, the solenoid valves open to permit hot water to flow into storage tanks. This process optimizes energy efficiency by ensuring that only appropriate quantities of water are heated and circulated, considerably enhancing the overall effectiveness of a solar heating system.

The operation of these valves is governed by an electrical signal that dictates whether to open or close the valve. This intelligent automation reduces the need for manual intervention while ensuring that solar energy is harnessed efficiently. Additionally, solenoid valves can prevent overheating and facilitate system protection by shutting off flow when temperatures exceed safe limits. Thus, their functionality is integral to maximizing the efficacy of solar systems and ensuring reliable operation.

HOW OFTEN SHOULD SOLENOID VALVES BE INSPECTED OR REPLACED?

Regular maintenance and inspection of solenoid valves are paramount in ensuring optimal performance in solar heating systems. While specific requirements can vary based on usage and environmental factors, a general guideline recommends these valves be inspected at least once a year. During these inspections, it’s essential to check for signs of wear, leaks, or corrosion, as such issues can impair valve performance and disrupt the entire system’s efficiency.

In cases where frequent cycling occurs or high flow rates are present, more frequent checks may be warranted. If any anomalies are detected that could indicate failing components, such as erratic operation of the valves or unusual noises, immediate replacement is advised. Regular maintenance not only prolongs the life of the solenoid valves but also saves money in the long run by preventing costly repairs or system replacements caused by oversights.

WHAT ARE THE SIGNS THAT A SOLENOID VALVE NEEDS REPLACEMENT?

Detecting when a solenoid valve requires replacement can often be guided by identifiable signs of failure. Common indicators include irregular fluid flow where one might experience temperature fluctuations or inadequate hot water delivery as a typical symptom. Additionally, if valves fail to open or close properly despite receiving electrical signals, this may signify internal component wear that necessitates replacement.

Physical signs such as visible corrosion, leaking, or damage around the valve and its fittings may also suggest a need for immediate attention. Malfunctions can lead to inefficient operation of the entire solar system, increasing energy consumption and decreasing overall efficiency. Regular inspections will help identify these problems early and indicate when valve replacement is necessary to maintain the integrity of the system.

DAUNTING TASKS REQUIRE A STRATEGIC APPROACH

Your expertise in dismantling a solar solenoid valve network can greatly improve the understanding of these systems and promote sustainable practices. Every precaution must be observed, and a thorough understanding of the components involved aids in executing the entire task effectively. Preparing with appropriate tools and safety gear, followed by meticulous disconnection and removal of components, ensures safety and efficiency. Furthermore, considering disposal practices and preventive measures for future installations promotes eco-responsibility and system longevity.

Avoiding common mistakes, maintaining regular inspections, and recognizing signs of component failure contribute to sustained performance and efficiency. By nurturing awareness of the systematic approach necessary for dismantling and maintaining solar solenoid valve networks, individuals can foster an environment that promotes optimal energy utilization and sustainability. Emphasizing the importance of this knowledge base allows for a more extensive and successful engagement with solar technologies, ensuring that both professionals and amateurs can confidently navigate dismantlement tasks while safeguarding ecological integrity.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-solenoid-valve-network/