1. Understanding the Dismantling Process: Dismantling a solar solenoid valve requires precision and knowledge of the valve’s components—1. Identify the type of solar solenoid valve you have, 2. Gather the necessary tools such as screwdrivers and wrenches, 3. Disconnect power supply to avoid accidents, 4. Ensure safety by wearing protective gear, 5. Follow specific instructions based on manufacturer’s guidelines and documentation. Each of these points plays a crucial role in ensuring a seamless and effective dismantling process.

- Providing Detailed Steps for Safe Dismantling: Understanding how to properly dismantle the solar solenoid valve involves multiple steps and precautions. Emphasizing the importance of safety is paramount; disconnecting electricity minimizes the risk of electric shock or accidental activation. Furthermore, having the appropriate tools ensures that the disassembly will be smooth and efficient. When there are specific guidelines or manuals from the manufacturer, following these closely will provide significant assistance in understanding how the valve is assembled and how to take it apart methodically. By adopting a cautious approach and meticulously adhering to these instructions, one can effectively dismantle the valve without causing damage to its components or compromising its functionality.

- INTRODUCTION TO THE VALVE AND ITS FUNCTIONS

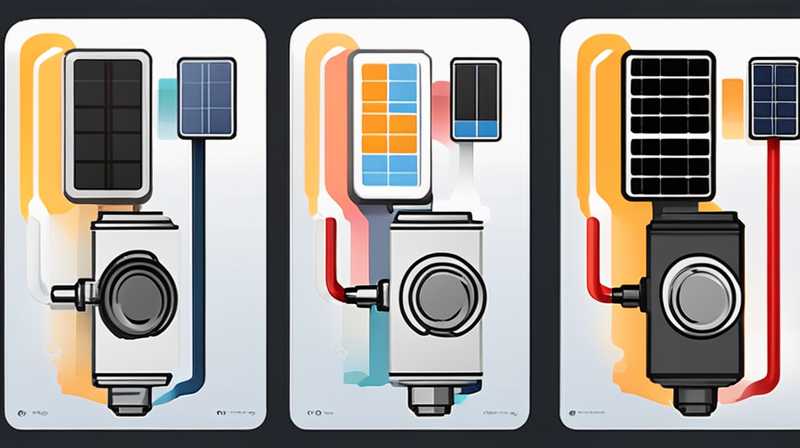

Understanding the solar solenoid valve is fundamental to successfully dismantling it. A solar solenoid valve acts as an intermediary between the solar system’s components, controlling the flow of fluids based on electrical signals. The primary function of this valve is to regulate the movement of water or other fluids within the system, providing effective management of thermal energy collected from solar panels. These valves are often used in greenhouse watering systems, pool heating, or solar heating applications.

Knowing the mechanics behind the valve’s operation allows for a more strategic dismantling process. The valve consists of several critical parts, including the solenoid coil, the valve body, and a plunger. The solenoid coil generates a magnetic field when power is applied, which moves the plunger to open or close the valve. Each component is designed to perform a specific function, contributing to the overall efficiency of the solar system. Understanding these functions helps to identify which parts must be disassembled first, ensuring a logical and methodical approach to dismantling the unit.

- SAFETY PRECAUTIONS BEFORE DISMANTLING

Prior to commencing the dismantling of the solar solenoid valve, implementing safety precautions is essential. Assembling the necessary tools is the first step; having access to screwdrivers, wrenches, and pliers will facilitate the process. Furthermore, disconnecting the power source is crucial. A solenoid valve operates electrically, meaning any residual electricity poses a spark risk or worse, leading to hazardous situations. Always ensure you are working in a safe and controlled environment, free from distractions that could lead to mistakes.

Another vital aspect of safety includes wearing protective gear. Gloves, safety goggles, and even a face mask can help prevent injury during the disassembly process. Performing the task with proper safety measures promotes not just personal safety, but also preserves the integrity of the valve components. Without adequate protection, one could risk cuts, scrapes, or exposure to hazardous materials. Therefore, engaging all safety protocols can lead to a successful dismantling without injury or equipment damage.

- TOOLS AND EQUIPMENT REQUIRED FOR DISMANTLING

Having the proper tools and equipment can immensely impact the success of dismantling a solar solenoid valve. The primary tools necessary include a flathead and Phillips screwdriver, a set of wrenches, and pliers. Specialty tools may also be required depending on the specific design of the valve in question. For example, if the valve is secured by a unique fastener type, it’s crucial to have the right tool on hand to avoid stripping screws or damaging components.

Additionally, a multimeter can be beneficial, particularly when diagnosing problems post-dismantling. Using a multimeter allows for testing electrical continuity and diagnosing whether the solenoid coil is functional. Tackling the dismantlement equipped with the right tools assures a smoother process, minimizes risk, and can save time.

- DISASSEMBLY STEPS FOR THE SOLENOID VALVE

Engaging the dismantling of a solar solenoid valve necessitates a systematic approach. Follow these steps for optimal effectiveness:

- Step 1: Disconnect the Power Supply. Before beginning, ensure the valve is completely de-energized to avoid electrical hazards. This is the foremost step critical for safety. Label wires if necessary to avoid confusion upon reassembly.

-

Step 2: Remove the Outer Cover. Depending on the valve model, there may be screws or clips securing the outer casing. Utilize appropriate screwdriver sizes to prevent damage when loosening these fasteners.

Through meticulous application of these steps, individuals can proficiently dismantle the valve ensuring that all parts remain in a condition ready for either cleaning or replacement.

- EXAMINING EACH COMPONENT DURING DISASSEMBLY

Upon removal of the outer casing, examining each internal component meticulously will yield insights into the system’s operation and convey the repair or replacement necessity. Parts such as the solenoid coil should be inspected for signs of wear or discoloration, indicating overheating or malfunction. Similarly, the plunger must be checked to ensure it moves freely without obstruction; this plays a critical role in the effective opening and closing of the valve.

Moreover, valves may accumulate debris or mineral deposits over time. Cleaning these components thoroughly is essential to reestablishing optimal performance post-reassembly. Proper cleaning methods involve using a soft cloth and a suitable solvent, ensuring that no damage is done to sensitive components. Practically diagnosing any form of mechanical dysfunction at this stage will prepare for reassembly insights that are often crucial for the valve’s long-term efficiency.

- ENSURING PROPER REASSEMBLY OF THE VALVE

After dismantling and inspecting, ensuring proper reassembly is equally important. Before putting everything back together, review the condition of all components. Replace any damaged parts; utilizing OEM parts will ensure compatibility and maintain system integrity. Employing a systematic approach while reassembling will significantly reduce the chance of errors.

When rejoining various sections, make sure to follow the reverse order of disassembly. Use a torque wrench if necessary to ensure that screws and bolts are fastened to the correct specification. Pay attention to wiring and any potential pinch points that may cause failure once the valve is operational again. The entire process of reassembly should maintain the integrity achieved during disassembly, leaving no room for compromise in performance.

- FREQUENTLY ASKED QUESTIONS

Q: WHAT ARE COMMON SIGNS THAT INDICATE A SOLENOID VALVE NEEDS DISMANTLING?

When a solar solenoid valve is malfunctioning, there are typical symptoms that may indicate it requires attention. For instance, if you notice a lack of fluid flow during system operation, it could signify that the valve is stuck in the closed position. Additionally, unusual noises such as hissing or rattling when the valve is energized may indicate problems within the valve itself. Moreover, visual signs such as leaks around the valve body or corrosion can indicate both wear and necessity for dismantling to address these defects properly. By promptly addressing these symptoms, you can effectively maintain system performance and efficiency.

Q: HOW CAN ONE TELL IF A SOLENOID VALVE REQUIRES REPLACEMENT INSTEAD OF REPAIR?

Determining whether to replace or repair a solar solenoid valve hinges on various factors. Firstly, if there is significant corrosion, cracks, or damage to the valve body itself, a replacement may be more economically viable. Furthermore, if the internal components such as the solenoid coil do not respond after thorough cleaning, it could indicate irreversible damage. Routine inspections of internal mechanisms will provide insights into the necessity of replacement. Given the potential risks and inefficiencies of a malfunctioning valve, weighing the cost of repair against the cost of replacement is essential for informed decision-making.

Q: IS IT ADVISABLE TO ATTEMPT DISMANTLING A SOLENOID VALVE WITHOUT PROFESSIONAL HELP?

While it is possible for individuals to undertake the dismantling of a solar solenoid valve, doing so without the guidance of a professional can pose risks. If you lack prior experience or understanding of electrical and mechanical components, it could lead to further damage or personal injury during the process. Furthermore, interface issues resulting from poorly executed repairs can decrease system efficiency and lead to additional costs. Ideally, individuals should consider consulting professionals or seeking robust tutorials before proceeding with dismantling. This strategy will ensure safety and enhance the likelihood of successfully restoring system functionality.

- IMPORTANCE OF MAINTENANCE POST-DISMANTLING

Upon successful reassembly, routine maintenance becomes imperative for ensuring durability and functionality of the solar solenoid valve. Regular monitoring and inspection can preemptively identify potential issues before they escalate to the point of requiring significant repairs. Documenting any findings during these inspections will help in understanding the valve’s performance trends over time, which can further inform future maintenance schedules.

Additionally, performing occasional cleaning can effectively prolong the valve’s lifespan. Accumulation can inevitably lead to malfunctions; employing preventive measures will not only enhance the valve’s performance but also improve the overall efficiency of the solar system. By actively participating in maintenance, users endorse a proactive stance toward ensuring optimal operations within their solar systems.

In summary, dismantling a solar solenoid valve involves a multi-faceted approach that emphasizes safety, systematic procedure, and professional know-how. Engaging in the process without proper preparation and knowledge could lead to fundamental issues that may impede valve functionality. The understanding gained from recognizing the function and structure of the valve, along with adherence to safety measures, creates an effective dismantling strategy. Maintenance routines following reassembly further compliment this process, ensuring long-lasting performance of the valve and optimizing the solar system’s functionality.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-solenoid-valve/