To effectively dismantle a solar drain valve, one must follow several crucial steps for a thorough and safe process. 1. Gather necessary tools and safety equipment, 2. Understand the valve components, 3. Disconnect the valve from the system, 4. Carefully remove the valve components. Each of these points plays a significant role in ensuring the task is performed without damage or injury. The most vital aspect is understanding the valve components, as this knowledge will guide the disassembly process without causing disruption to connected systems. By familiarizing oneself with the parts and their functions, the entire disassembly can be executed with precision and confidence.

UNDERSTANDING THE SOLAR DRAIN VALVE

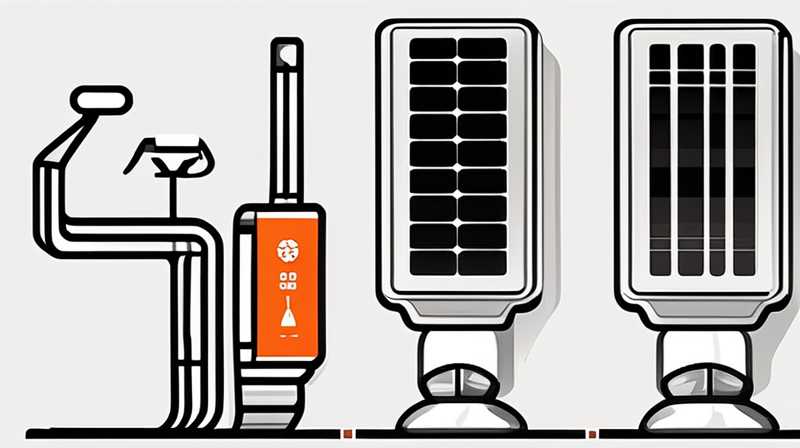

The solar drain valve serves a crucial role in the operational efficiency of a solar heating system. To engage effectively in the dismantling process, one must first comprehend the valve’s function and the types that are commonly found in solar setups. Their primary purpose is to facilitate the drainage of fluids at strategic points in the system to prevent freezing and other issues during cooler months.

Solar drain valves typically exist in several configurations, including manual, automatic, and pressure relief valves. Each has its unique properties and specifications that may affect the dismantling approach. For instance, manual valves may require the operator to adjust the opening and closing mechanisms physically, whereas automatic valves tend to consist of sensors and springs designed to respond to specific system pressures.

Moreover, knowing the materials from which these valves are constructed is crucial. Many solar drain valves are made from plastic, brass, or a combination of metals, all of which have different response behaviors to heat and pressure. Understanding these materials can also minimize the risk of damaging the valve or associated components during the disassembly effort.

GATHERING NECESSARY TOOLS

Before embarking on the disassembly journey, it is essential to assemble all required tools. 1. Tools commonly needed include wrenches, screwdrivers, a utility knife, and a pipe sealant, 2. Safety gear must also be at hand—gloves, safety goggles, and, potentially, a mask. Each object plays a vital role in ensuring safety and efficiency throughout the procedure.

Wrenches and screwdrivers are pivotal for loosening any bolts or screws that hold the valve in place. The utility knife may come in handy for cutting through any adhesive or sealant used in securing the valve parts. Pipe sealant is crucial for reassembly to prevent future leaks.

When selecting tools, it is advisable to opt for durable and reliable equipment, as inferior tools can lead to accidents or damage to the valve components. Ensuring that safety gear is worn will help avoid injuries. For instance, gloves protect hands from sharp edges or contaminants, while goggles shield eyes from debris during the disassembly. Having the right set of tools and safety equipment significantly enhances the likelihood of a successful dismantling process.

DISCONNECTING THE VALVE FROM THE SYSTEM

Prior to proceeding with dismantling, it is imperative to disconnect the solar drain valve from its associated plumbing and electrical connections. 1. Identifying the relevant connections is fundamental; 2. Properly shutting off the system prior to disconnection is a critical safety measure. This stage is essential in preventing any unforeseen accidents or damage to the solar heating system.

Begin by locating the two sides of the drain valve—the inlet and the outlet. Assess whether there are additional components (such as unions or adapters) facilitating these connections. Utilizing the appropriate tools, loosen and remove any fittings to disconnect the valve from the piping network. Make certain to keep track of all components removed so that reassembly once the valve is serviced is more manageable.

Shutting the system down requires not only turning off the main power but also ensuring all valves are closed and pressure is relieved from the lines. This will not only prevent fluid from escaping during disassembly but also safeguard operators from potential hazards arising from pressurized fluids.

DISASSEMBLING THE VALVE COMPONENTS

Once the valve is disconnected, the actual dismantling can commence. 1. Beginning with the removal of the outer casing is typically the first step; 2. Proceeding to additional internal components can follow. This process demands careful attention to detail and a steady hand.

Using the applicable tools, commence by unscrewing or unclipping any screws or fasteners securing the casing. It’s beneficial to note the arrangement and sizes of screws, potentially using a designated container for organization. Some valves may also have locking mechanisms or clips that need to be carefully disengaged. The objective at this stage is to ensure that all outer components are safely set aside without causing damage.

Upon exposing the inner workings of the valve, inspect the assembly. Many solar drain valves contain springs, seals, or diaphragms that can be quite fragile. Carefully lifting or unseating these components is essential to avoid breaking them. It can also be helpful to document the internal structure with photographs for reference during the reassembly phase.

CLEANING AND INSPECTING COMPONENTS

After successfully dismantling the solar drain valve, it is time to undergo an inspection and cleaning stage. 1. Inspecting each component for wear or damage, 2. Thoroughly cleaning parts to remove debris or build-up. This stage holds great importance, as it will determine whether parts need replacement or if they are suitable for reinstallation.

Closely examine components such as seals and gaskets for cracks or degradation, as these are critical to maintaining the valve’s functionality. If any defects are found, they should be replaced in order to prevent future leaks or malfunctions.

Cleaning the valve components is equally as crucial. Utilizing warm, soapy water or specific cleaning solutions designed for metals or plastics can help remove built-up deposits, mineral deposits, or other obstructions that could hinder the valve’s operation in the future. Subsequent to cleaning, ensure the components are adequately dried before reassembly.

REASSEMBLING THE SOLAR DRAIN VALVE

Once all parts have been cleaned and inspected, the reassembly process can begin. 1. Following the order in which components were removed is crucial; 2. Ensuring proper alignment and fit for each component is essential to avoid leaks. The reconfiguration must also be performed methodically, just as dismantling was done.

Begin by placing the cleaned internal components back into the valve casing following a reverse order of disassembly. Utilize photographs or notes taken during the dismantling process to confirm correct placement. This thoroughness helps reduce errors that can lead to leaks or operational inefficiencies.

Utilization of new seals or gaskets that were identified during the inspection is critical at this juncture. These components help facilitate an airtight closure when the valve is reconnected to the plumbing system. As the reassembly progresses, ensure that screws, bolts, and clips are tightened adequately to maintain structural integrity, while avoiding over-tightening that could cause damage.

FINAL CONNECTIONS AND TESTING

After successfully reconstructing the solar drain valve, the final stage involves the reconnection and testing of the valve within the solar heating system. 1. Begin reconnecting the valve to the plumbing system with careful attention to proper orientation; 2. Testing the assembled valve for leaks or operational efficiency is necessary before resuming normal use.

Reconnecting the valve involves reversing the disconnection process. Refer back to notes or photographs to ensure that all connections are appropriately secured. At this stage, it’s imperative to recheck the integrity of all fittings, as loose connections can lead to leaks.

Following reconnection, carefully restore power to the solar heating system and open any valves that were previously closed. Observing the valve for leaks during operation is essential for ensuring successful repairs. A thorough inspection of the valve during the initial operational phase can confirm that the dismantling and reassembly efforts were executed effectively. Continuous monitoring in the days following is also advisable to catch any potential issues early on.

FAQs

WHAT TOOLS ARE NECESSARY FOR DISMANTLING A SOLAR DRAIN VALVE?

The proper tools are key to effectively disassembling a solar drain valve. Essential instruments generally include a variety of wrenches, screwdrivers, and a utility knife. These tools allow for the loosening of screws, bolts, or even seals that may have become rigidly attached over time.

Also, consider acquiring specialty tools like a torque wrench for precision fittings that require a specific level of tightness. Pipe sealants are essential for resealing during reassembly, ensuring that no leaks occur at the connection points. It is equally important to don protective equipment such as gloves and safety goggles to safeguard from debris or sharp edges when engaged in the service process. Having quality tools and safety gear ready significantly streamlines the disassembly and reassembly efforts.

HOW DO I KNOW IF MY SOLAR DRAIN VALVE NEEDS REPAIRS?

It’s vital to know the signs of wear or malfunction to address any required repairs for the solar drain valve. Indicators can range from visible leaks around fittings to decreased efficiency in the heating system. A malfunctioning valve may also lead to fluctuating pressure or inconsistent temperatures in the solar system.

Regular maintenance logs can help catalog any unusual activity or findings over time, allowing for a proactive approach to repairs. Notably, if the valve produces strange noises, such as rattling or chirping, this may indicate internal issues requiring immediate attention. Keeping abreast of these signs can prevent costly damages or system failures down the line.

CAN I DISMANTLE A SOLAR DRAIN VALVE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Dismantling a solar drain valve can be executed by individuals with adequate basic mechanical knowledge and appropriate tools. However, if you are unsure about any aspect of the process, especially within a complex system, it may be wise to consult a professional. 1. Professional assistance can help mitigate risks associated with improper handling; 2. They possess the skills needed to ensure a full, effective service.

Should you choose to proceed independently, it is advisable to document your process and follow a set guide to ensure all stages are executed accurately. Ultimately, the decision should stem from an individual’s comfort level with mechanical tasks and the complexity of their solar systems.

FURTHER REMARKS ON VALVE Dismantling AND MAINTENANCE

The dismantling process of a solar drain valve is not merely a technical task, but an intricate procedure that necessitates attention to detail and a methodical approach. With comprehension of the components and the correct tools in hand, one can navigate the dismantling with confidence. Each step taken during this process is paramount, from disconnecting the valve to thoroughly inspecting and cleaning its parts. Each action contributes significantly to extending the lifespan of the valve and ensuring optimal functionality of the associated solar heating system. Moreover, thorough reassembly is crucial, as any oversight in this stage could lead to future problems, including leaks or valve inefficiencies. Regular monitoring and maintenance following the service can help diagnose issues early on before they escalate into costly repairs. Prioritizing knowledge, safety, and diligence throughout every phase fosters a successful dismantling experience. Additionally, recognizing the signs of wear can guide an operator toward timely repairs, whether handled in-house or by professionals, ultimately preserving the efficiency of the solar heating systems designed to provide sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-drain-valve/