To effectively dismantle a solar circulation pump, it is crucial to follow specific steps and precautions. 1. Turn off all power sources, ensuring safety before starting the disassembly process. 2. Disconnect all connections, including electrical and plumbing. 3. Gather necessary tools, such as wrenches and screwdrivers. 4. Carefully remove the pump casing, ensuring no damage to other components. 5. Safely extract the internal mechanisms, paying attention to how each part fits together to facilitate reassembly if necessary. Detailed attention is required during this process, particularly in noting how the parts connect and their orientation, which aids in reinstallation.

The disassembly procedure should be approached methodically to prevent damage to sensitive internal components. It’s advisable to take photographs of each stage of dismantling as a reference for reassembly.

1. UNDERSTANDING THE SOLAR CIRCULATION PUMP

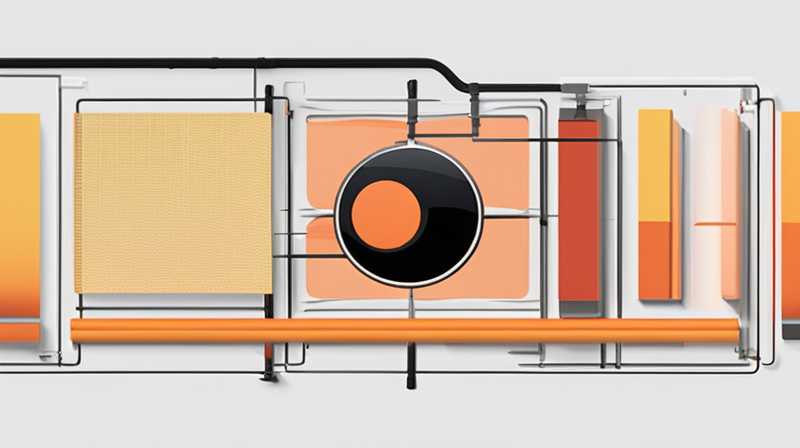

Prior to embarking on the disassembly process, it is essential to understand the fundamental purpose and functionality of the solar circulation pump. This device serves a critical role in solar thermal systems, facilitating the transfer of heat from solar collectors to storage tanks. Such pumps are engineered to operate efficiently, working on a minimal energy footprint, often powered solely by solar energy.

The mechanical components of these pumps generally consist of a motor assembly, impeller, casing, and various fittings for both the electrical supply and hydraulic connections. Understanding the functionality of each part will not only guide the dismantling process but will also promote efficient maintenance practices. By grasping the relationship between each component, the user can more effectively identify potential issues and troubleshoot accordingly.

2. PREPARING FOR DISASSEMBLY

Preparation is key to a successful dismantling attempt. Before proceeding, it’s paramount to gather all necessary tools and materials. Essential items include a variety of screwdrivers (both Philips and flathead), adjustable wrenches, pliers, and, if available, a torque wrench for nuts and bolts that require a specific amount of force for removal. Additionally, employing safety gear such as gloves and goggles can help safeguard against potential injuries.

A thorough cleaning of the area surrounding the pump is advisable. Ensuring a tidy workspace minimizes the risk of losing small components and makes it easier to manage tools during disassembly. Furthermore, it’s an effective practice to keep a small container or bag for the nuts, bolts, and other easily misplaced items. Labeling components as they are removed can also be beneficial, particularly for those who may not be experienced with the inner workings of pumps.

3. DISCONNECTING POWER SOURCES

The first major action during the dismantling process involves disconnecting the power supply to the pump. This step cannot be overstated, as working with electrical components poses significant risks if proper precautions are not taken. Finding the correct circuit breaker or switch to shut off electricity ensures that no accidental shocks occur during disassembly.

For pumps that are integrated with a larger solar thermal system, it is advisable to consult the system manual or wiring diagram. These documents provide critical information regarding how power flows to the pump and may indicate other sections of the system that require disconnection. Confirming that energy has been successfully turned off can be validated using a multimeter to check for voltage in connected wires.

4. DISCONNECTING PLUMBING LINES

Once electrical connections are secured, attention turns to the plumbing lines connected to the pump. Using the appropriate wrenches, both the inlet and outlet pipes can be carefully loosened and removed. It is often beneficial to have a few towels or a basin on hand to catch any residual water that may remain in the lines.

When disconnecting pipes, it’s critical to use caution in order to avoid stripping threads or damaging fittings. Taking note of how hoses and connections are arranged can prevent misalignment issues during reinstallation. If necessary, marking each connection on both the pump and the piping can act as a visual guide.

5. REMOVING THE CASING

After all external connections have been disengaged, the next step focuses on the removal of the pump casing. Pump casings are typically held in place with several screws or bolts. It’s vital to use the correct size and type of screwdriver or wrench to avoid damaging these fasteners. Removing them in a systematic fashion ensures that everything is accessible and can be reassembled without difficulty.

Once the casing is off, observe the internal arrangement of components. Internal components may include the motor, impeller, and seals, which should all be carefully documented or photographed for reference. This attention to detail during disassembly significantly aids in the clarity of the reassembly process later.

6. DISASSEMBLING INTERNAL COMPONENTS

With the casing removed, focus shifts to the internal components. The motor assembly, often composed of several parts, should be dismantled with care. Detaching the motor may require specialized knowledge, as it involves internal wiring and electronic connections. Take a moment to understand how each part fits within the broader context of the pump’s functionality.

The impeller, which operates by rotating to facilitate fluid movement, should also be removed. Its positioning should be noted, along with any accompanying seals or washers. These components play a crucial role in efficiency and should be inspected for wear or damage. Understanding how these elements interact within the pump will also contribute greatly to effective reassembly.

7. REASSEMBLY PREPARATIONS

Once disassembly is complete, it becomes crucial to prepare for the reassembly phase. Inspecting all components for signs of wear, corrosion, or damage helps determine whether any parts need to be replaced. If any worn components are identified, sourcing replacements ahead of time can save significant delays when it comes time to put everything back together.

Cleaning each component during inspection can also enhance performance once the pump is reassembled. Removing dirt and debris ensures that the seals fit properly, while clean components are likely to function smoothly. Paying attention to proper lubrication of moving parts will also enhance the longevity of the pump’s operation.

8. TROUBLESHOOTING COMMON ISSUES

Familiarity with common issues related to solar circulation pump operation can be advantageous, as it enables proactive measures during reassembly. One frequent problem involves loss of prime, where the pump fails to circulate fluid properly due to air trapped within. Proper bleeding of the system can prevent such issues.

Another common issue is related to vibrations and noise. These are often indicative of misalignment or loose components. During the reassembly process, ensure that all fasteners are secured and that the alignment is maintained throughout. Addressing these troubleshooting aspects not only enhances the effectiveness of the pump but also mitigates long-term wear and tear.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING A SOLAR CIRCULATION PUMP?

The effective disassembly of a solar circulation pump requires specific tools to ensure a smooth process. Essential tools include various screwdrivers tailored to Philips and flathead screws, adjustable wrenches for loosening nuts and bolts, as well as pliers designed to provide a firm grip during disassembly. Moreover, the inclusion of a torque wrench proves beneficial in handling tightly secured components, as overtightening may risk damaging sensitive elements during reassembly.

In addition to the standard tools, having safety equipment on hand greatly increases safety during the process. Safety goggles protect against debris, while gloves minimize the risk of injury when handling sharp or pointed components. It is advisable to have a container for small parts to avoid misplacing nuts and bolts, which are often integral for proper reassembly. Such careful preparation ensures that the process runs efficiently and that all necessary items are at hand as the work progresses.

HOW CAN I ENSURE SAFE DISASSEMBLY OF THE PUMP?

Safety during the disassembly of a solar circulation pump cannot be overlooked. To ensure safety, begin by turning off the power supply to the device. Locate the appropriate circuit breaker that provides energy to the pump and confirm that it is switched off, using a multimeter if necessary. This critical step prevents accidental electrical shocks, which can be hazardous.

Wearing proper safety gear is also essential. Employing safety goggles can protect eyes from debris, while gloves guard against sharp edges. Additionally, have a well-organized workspace, free from clutter, to minimize the risk of slipping or losing tools. Planning for any potential water leaks by having absorbent materials on hand can also aid in maintaining cleanliness and safety during the disassembly process. By adhering to these safety protocols, the dismantling process can proceed smoothly, reducing risks to both the individual conducting the work and the functional integrity of the pump itself.

WHAT COMMON MISTAKES SHOULD I AVOID WHEN DISMANTLING A SOLAR CIRCULATION PUMP?

Avoiding common pitfalls during the disassembly of a solar circulation pump is crucial to ensuring an efficient process. One significant mistake is neglecting to turn off power to the pump before beginning work; this oversight could result in severe electric shock. Thus, always verify that the energy supplies have been disconnected beforehand.

Another frequent error involves rushing through the disassembly steps without careful documentation of how parts are arranged. Failing to take photographs or notes can lead to complications when reassembling the device. Each component has a specific orientation and arrangement critical to optimal operation, and losing track of these details can complicate the process later. Moreover, using incorrect tools for removing screws or bolts may damage these fasteners, potentially rendering them unusable. By being mindful of these common mistakes, the disassembly procedure can be executed more effectively and with less frustration.

In summary, dismantling a solar circulation pump involves careful preparation, a focus on safety, and meticulous attention to detail. The overall process is quite intricate, yet by understanding the various components and procedures clearly, anyone can undertake this task successfully. Making sure to turn off the power supply and disconnect all connections is paramount. Utilizing a gathering of the required tools ahead of time simplifies the process, while attentive documentation ensures easy reassembly later. Addressing potential issues during the reassembly phase can greatly enhance the pump’s long-term performance and reliability. When each of these steps is approached carefully and systematically, the entire operation can be accomplished efficiently, facilitating any necessary repairs or maintenance with ease.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-solar-circulation-pump/