To disassemble the side of a solar thermal barrel, one should follow a series of methodical steps. 1. Assess the current setup carefully, ensuring all necessary tools are on hand and safety precautions are observed. 2. Identify and remove any components that may obstruct access to the barrel. 3. Follow a systematic approach to detach the side wall, considering different joining methods used in the assembly. 4. Be mindful of potential hazards, such as sharp edges or pressurized fluids. Among these elements, a careful examination of attachments and disconnections is paramount, as improper handling may lead to damage or injury.

UNDERSTANDING SOLAR THERMAL BARRELS

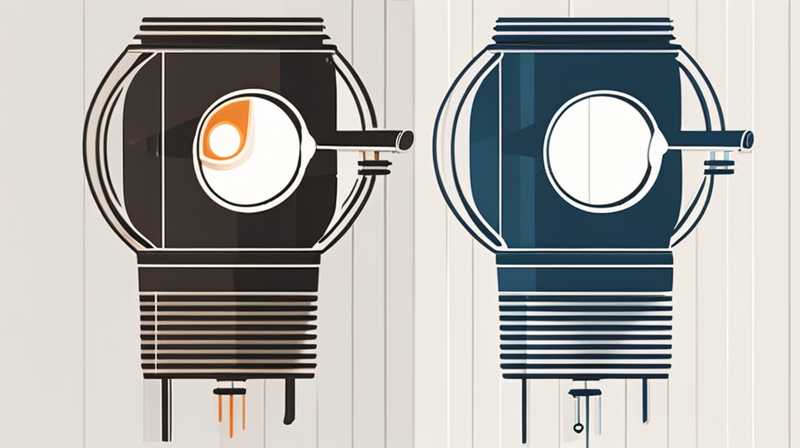

Solar thermal barrels are integral components in harnessing solar energy to heat water. These systems typically comprise a series of pipes and a highly insulated storage tank. The thermal energy from the sun heats the water circulating through these pipes, making solar thermal systems both eco-friendly and efficient alternatives. Understanding the structure of these barrels is crucial for maintenance and repairs.

When examining the construction of a solar thermal barrel, it becomes evident that the system relies on various materials designed to withstand external factors, such as temperature fluctuations and physical pressure. The typical barrel consists of metal or sometimes plastic, highlighted by a robust insulating layer that minimizes heat loss. Consequently, dismantling the side of the barrel requires not only knowledge of its assembly but also the right tools to avoid damaging the components during the process.

PREPARATION FOR DISMANTLING

Proper preparation cannot be overstated when it comes to dismantling components like the side of a solar thermal barrel. 1. Ensure that the system is completely decommissioned, meaning that no internal fluids remain and no power sources are engaged. 2. Gather appropriate safety gear such as gloves, goggles, and protective clothing. 3. Have specialized tools ready, including wrenches, screwdrivers, and possibly a saw, depending on the barrel’s construction.

One of the first steps in preparation involves ensuring that the barrel has cooled down sufficiently to prevent burns or injuries. Water temperature can remain quite high even after the system is turned off. Adequate time must be allowed for the entire assembly to reach a safe temperature before proceeding.

Additionally, a thorough inspection must precede any physical effort. Look for adjustable fittings, screws, or rivets that may not be readily visible upon first glance. Documenting the layout and configuration of the system can help later during reassembly. Photographs or sketches detailing the initial state provide a valuable reference to ensure that all components are returned to their rightful positions after the disassembly is complete.

REMOVAL OF EXTERNAL COMPONENTS

Before reaching the side of the barrel, the exterior elements must be attended to. 1. Remove any protective covers or insulation that serves as a barrier. 2. Detach ancillary equipment such as pumps, valves, or gauges that may obstruct access.

In many cases, the insulation provides both thermal protection and physical safeguarding of the barrel itself. Carefully cutting away or peeling back insulation not only plays a major role in exposing the sides but also helps to keep materials intact. If the insulation is glued or fitted tightly, take care to minimize damage, as re-insulation may be required later.

After exposing the surface of the solar thermal barrel, the next task is to identify and unfasten any additional components that may hinder the sidewall removal process. Common items include electrical connections or gauges that monitor temperatures and pressure. Before unscrewing these elements, ensure all systems are fully powered down, and safely store loose components for later reinstallation.

DETAILED DISASSEMBLY OF THE SIDE

Having prepared the surrounding components, focus shifts to the main task of detaching the side of the barrel. 1. Identify all screws, bolts, or rivets that secure the side wall in place. 2. Work methodically to untighten or cut these fasteners without exerting too much force.

While most barrels utilize screws or bolts for easy disassembly, some may employ rivets which require more effort. In cases with riveted joints, special care must be taken to ensure that the material isn’t compromised. Utilizing an appropriate drill bit can help in safely severing the rivets, allowing for smoother removal of the panel without the risk of damaging adjoining parts.

As disassembly progresses, study the way each component interacts with others. This not only fosters a better understanding of the barrel’s architecture but also informs future reconstruction efforts. If sections resist removal, re-evaluating the fasteners or potential catches might be necessary. Gradually and patiently working through these barriers prevents unexpected breaks or unwanted material stress.

HANDLING INTERNAL COMPONENTS

Once the side wall is removed, attention turns to the internal constructs of the solar thermal barrel. 1. Inspect the piping and heating elements with care, as they may also need servicing or replacement. 2. Ensure proper handling methods are utilized to prevent damage during maintenance activities.

Within the barrel, various pipes transport water to and from the heating source. It’s vital to observe any signs of wear, corrosion, or blockages that could affect overall performance. Tools such as inspection mirrors can assist in evaluating hard-to-reach areas, indicating whether thorough cleaning or replacement is warranted.

During this phase, attention should also be devoted to electrical connections linked to pumps or thermostats present within the system. Disconnecting these components can be tricky; hence, maintaining a clear organization of which wires correspond to each device aids in reassembly. A mistake here could lead to electrical faults that are not only inconvenient but pose potential safety hazards, underscoring the importance of careful documentation and methodical disassembly practices.

REASSEMBLY STRATEGIES

Completing the disassembly is only half the battle; reassembly presents its own challenges. 1. Start by inspecting all parts for damage, replacing any broken or worn-out components. 2. Lay out parts according to the documented organizational scheme to streamline the process.

Taking the time to thoroughly clean and assess each component for damage before proceeding to reassembly is essential. This preventative measure addresses any existing issues, thereby increasing the longevity and efficiency of the solar thermal barrel once it is re-energized.

Utilize the reference documents gathered during the disassembly process as guides during reassembly. Pay close attention to the orientation of parts, especially with complex assemblies. In scenarios where different parts may fit interchangeably, double-check labels or markings to ensure proper installation. Taking a meticulous approach to reassembling minimizes the risk of overlook that could lead to later malfunctions.

COMMON PITFALLS TO AVOID

Though the dismantling and reassembly process may seem straightforward, several pitfalls can easily derail efforts. 1. Rushing through inspections may lead to overlooked components, resulting in unnecessary repairs later. 2. Neglecting to follow safety protocols while disassembling can lead to serious injuries.

To safeguard against hasty inspections, allocate sufficient time for every step of the disassembly and reassembly process. Remaining methodical allows for comprehensive evaluations, which identify potential issues before they develop into more significant problems.

Mechanical safety is paramount; obey all recommended procedures concerning safety gear and equipment handling. A failure to do so can lead to accidents that may be prevented through a little caution. Using the right tools to facilitate disassembly and adhering to visual guides can be deviations that prevent dire outcomes.

RECOMMENDED MAINTENANCE PRACTICES

To prolong the lifespan of a solar thermal barrel, consistent maintenance is imperative. 1. Schedule regular inspections to monitor the health of both internal and external components throughout the year. 2. Clean and replace parts as necessary, especially those subject to wear from heat or moisture.

By maintaining a routine schedule for inspections, potential issues can be identified before they escalate to dangerous levels. Recommended checks should assess the integrity of seals and valves, the cleanliness of piping, and the operational efficiency of thermal connections. Document findings to aid in comprehension of the barrel’s performance as time goes on.

Equally crucial is the attention paid to component cleanliness. Periodic flushing of the internal pipes can help eliminate blockages, minimizing the risks of inefficient heating. Beyond flushing, applying protective coatings to external walls can help guard against environmental wear, extending the overall usability of the solar thermal barrel.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NECESSARY FOR DISMANTLING?

The process of dismantling a solar thermal barrel typically requires specialized tools. Essential instruments include a socket or wrench set for loosening screws and bolts, screwdrivers compatible with the types of screws used on the barrel, and potentially a power drill for riveted connections. Further tools may include pliers for gripping or removing components and a utility knife for any cutting tasks related to insulation. Always ensure all tools are in good condition to avoid accidents.

Prior to beginning the disassembly process, gather all necessary tools and confirm their functionality. A well-prepared toolkit eases the overall dismantling journey and reduces the chance of interruptions due to the unavailability of essential instruments during critical operations. Depending on the age and design of the barrel, additional tools may be needed, so evaluating the situation beforehand provides a more smooth experience.

HOW TO ENSURE SAFETY DURING DISMANTLING?

Prioritizing safety is of utmost importance when dismantling a solar thermal barrel. Begin by wearing personal protective equipment (PPE) such as gloves, goggles, and masks to protect against injury from sharp edges and chemical exposure. Clear your workspace of hazards and ensure good ventilation if working indoors, preventing the build-up of potentially harmful fumes from oils or materials used in the barrel.

Ensuring that the system is completely powered down and devoid of water and pressurized fluids before commencing work is critical. A proper assessment of the materials involved contributes to minimizing risk further. Lastly, if in doubt about handling processes or uncertain about any component, consulting with a professional may prevent catastrophic failures during the dismantling endeavor.

IS PROFESSIONAL HELP NECESSARY FOR DISASSEMBLY?

While many individuals may possess the skills necessary to dismantle a solar thermal barrel independently, professional assistance can often enhance safety and efficiency. Experts can provide insights into potential complications that may not be immediately apparent, ensuring best practices are followed throughout the disassembly and reassembly process. Furthermore, they can help troubleshoot any unique challenges specific to the model in question.

Alternative scenarios exist; for those well-versed in mechanical systems, an independent effort is achievable. A thorough understanding of the system’s construction, accompanied by detailed documentation of disassembly processes, will aid during reassembly. Should complications arise, such as structural concerns or complex component interactions, opting for professional guidance ensures the integrity of the solar thermal barrel is upkept across all stages.

Completing the disassembly and reassembly of a solar thermal barrel demands careful attention, comprehensive preparation, and methodical preparation. Proper knowledge of the components and their interactions is essential, as is ensuring safety measures are in place throughout the process. The importance of adhering to best practices cannot be overstated; not only does meticulous attention enhance the overall longevity of the system, but it also ensures safety during the process. Maintaining a detailed documentation approach allows for seamless reassembly and future maintenance, highlighting the intricate relationship between parts, tools, and methods. Engaging knowledgeable professionals can simplify complexities and elevate the overall experience. Regular assessments alongside consistent upkeep practices fortify the operational efficiency of solar thermal barrels, allowing homeowners to harness the power of solar energy effectively. By following these guidelines, one can achieve satisfactory outcomes in both dismantling and reassembling solar thermal systems, ensuring their performance remains steadfast throughout their operational lifetime.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-side-of-the-solar-thermal-barrel/