Dismantling a porcelain core valve for a solar installation involves several key steps: 1. Preparation of Necessary Tools, 2. Understanding the Valve Structure, 3. Safe Dismantling Procedures, 4. Reinstallation and Testing. A detailed approach to each of these aspects is crucial for a successful dismantling and ensures that the components remain intact for future use. Many professionals recommend having a comprehensive understanding of the solar system’s water flow dynamics as a baseline. The process should be approached with care, as improper handling of the porcelain core can lead to damage or leaks.

1. PREPARATION OF NECESSARY TOOLS

Prior to embarking on the disassembly journey, it is essential to gather the correct tools. The right instruments ensure an efficient process and minimize risks associated with dismantling procedures. Key tools include a wrench set, screwdrivers (both Phillips and flat-head), safety goggles, gloves, pliers, and a soft cloth. Each of these items serves a specific function, contributing to both safety and the efficacy of the operation.

First, a wrench set is vital as it allows for the loosening of bolts and fittings that secure the valve. Using the right size prevents stripping and damaging threads. In addition, screwdrivers are necessary for various screws that may hold components of the valve together. Safety goggles are significant in protecting the eyes from debris or chemical splashes. Wearing gloves provides a safeguard against cuts and chemical irritations while handling the components.

Safety Considerations

Safety is not merely an option; it is a prerequisite throughout the dismantling process. Proper attire is crucial—gloves and safety goggles shield the individual from potential injuries. Moreover, the workspace should be cleared of unnecessary items to avoid distractions or accidents. A clean and organized area allows for a smooth workflow, reducing the risk of misplacing components during disassembly.

Understanding how each tool will interact with the elements of the valve is crucial. For instance, using pliers can grip slippery pieces securely, ensuring that they are not dropped during removal. Without the proper tools and safety measures in place, the risk of damaging the valve or injuring oneself increases significantly, making preparation a top priority.

2. UNDERSTANDING THE VALVE STRUCTURE

A thorough comprehension of the porcelain core valve is essential before proceeding with any physical actions. Understanding the anatomy of the valve promotes more effective disassembly, reducing the likelihood of errors. Porcelain core valves can vary in design, but they typically consist of several vital components, including the body, seat, and core. Each of these parts plays a critical role in the overall function of the valve.

The valve body houses the internal components and is often the most substantial part of the valve. Understanding where the inlet and outlet are located helps in determining how it interfaces with other plumbing. The seat is where the actual sealing occurs; recognizing its position can help avoid unnecessary damage during the dismantling process. Finally, the core element, often made from porcelain, functions to regulate the flow through the valve. Understanding the interaction between these components is crucial to successfully dismantling the item without causing any irreversible damage.

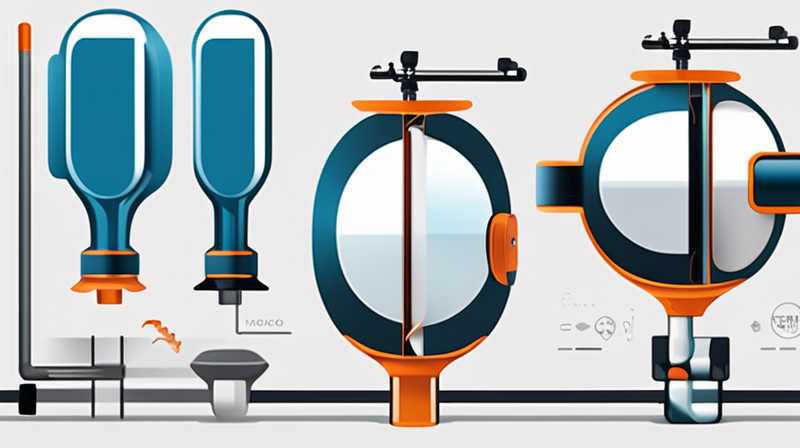

Visual Aids

Utilizing visual aids such as diagrams or schematics can significantly enhance comprehension. Not all structures are readily visible, and having an illustration ensures that one can identify the components quickly. There are many resources, including manuals, online videos, and community forums, which discuss the specifics of various valve designs. These platforms can provide additional strategies that may not be covered in basic manuals.

Incorporating visual aids into the preparation phase enhances confidence and provides a roadmap through the disassembly. By taking time to familiarize oneself with the valve’s internal structure, the actual dismantling process becomes more intuitive and systematic. A clear understanding allows for strategic planning and potential containment of issues that might arise during the process.

3. SAFE DISMANTLING PROCEDURES

Proceeding to the dismantling involves several methodical steps. Ensuring that the valve is completely disassociated from the system it serves is paramount before any physical engagement begins. This generally includes shutting off the water supply and releasing any pressure in the system. Failure to do so can result in water gushing from detached components, creating not only a messy situation but also the potential for injury.

Once ensured that the valve is no longer connected, initiate the disassembly by loosening any screws or bolts. Using the appropriate wrench sizes, slowly begin to turn without forcing them, as this could lead to stripped threads or broken components. It’s advisable to systematically remove each part and place them in an orderly fashion. Labelling parts during this process can significantly streamline the reassembly stage.

Minimizing Damage

Special care must be taken when manipulating the porcelain core. Porcelain is inherently brittle; thus, using a gentle touch when applying tools is crucial. Materials such as soft cloths can cushion any impacts if parts do drop inadvertently. Using wooden or plastic tools instead of metal for prying can reduce the likelihood of chipping or cracking the core.

When disassembling, maintaining the integrity of the surrounding plumbing fixtures is vital. Taking the extra effort to ensure that tools do not scratch or damage adjacent pipes prevents complications during reinstallation. Maintaining an organized and clean workspace further ensures that no contaminants enter the valve system, which could damage the components.

4. REINSTALLATION AND TESTING

Once the dismantling has been successfully completed, it is time to consider the intricate process of reinstalling the valve. Reinstallation must be approached with precision and caution, as this stage is critical for ensuring the functionality of the system. After reassembling the valve, it must be installed back into its designated position carefully.

Begin by aligning all of the components according to the original configuration. Adhering to any diagrams or labelling previously made will facilitate this step. Gradually tighten bolts and screws, starting from the middle sections and working outwards to distribute pressure evenly. Avoid overtightening, as this can lead to distortion or cracking of the porcelain core.

Testing for Leaks

After secure reinstallation, conducting tests for leaks becomes imperative. Restoring the water supply gradually and monitoring the functionality is crucial to confirm that the system operates seamlessly. Observing for any signs of leaks at connection points will indicate whether the reassembly was successful.

Implementing pressure tests can also be beneficial. By increasing the pressure slowly and monitoring how the valve responds, one can ensure that it is functioning as intended. If any irregularities arise, the area must be inspected for further adjustments or, if necessary, a complete disassembly and reassessment of the components.

FAQs

WHAT ARE THE SIGNS THAT A PORCELAIN CORE VALVE NEEDS Dismantling?

Several indicators signify that a porcelain core valve might require disassembly. First, any noticeable leaks are often a primary concern, suggesting that the valve seat or seals may be compromised. These leaks can lead to water loss or further damage within the plumbing system. Second, irregular water flow or inconsistent pressure might indicate that the valve is not functioning correctly, signaling a potential blockage or internal damage requiring investigation. Lastly, unusual noises during operation, such as rattling or whistling, could also suggest that internal components have become loose or are failing, warranting inspection and probable dismantling.

Understanding these warning signs can prevent more significant issues down the line. Additionally, if a system is operational for several years without intense maintenance, it may be suitable to proactively dismantle the valve for servicing.

HOW OFTEN SHOULD PORCELAIN CORE VALVES BE SERVICED?

While the required frequency for servicing porcelain core valves can depend on several variables, general guidelines can be applied. Typically, an inspection every two to five years can keep the system functioning optimally, especially in regions with variable water quality or conditions. Understanding the water’s mineral content is critical here; hard water can create deposits leading to blockages or reduced efficiency. Monitoring performance indicators such as water pressure and flow can give insight into whether a valve requires more frequent servicing.

Being proactive with maintenance can extend the life span of porcelain core valves and enhance the overall resilience of solar systems. In cases of heavy use or observable performance degradation, more frequent inspections may be necessary.

WHAT TO DO IF DAMAGE OCCURS DURING Dismantling?

Should any damage occur during the disassembly process, addressing the situation immediately is crucial. First, if the porcelain core is cracked or shattered, it must be replaced. Continuing to use a damaged component can lead to leaks and outright failure of the valve system. Many suppliers offer replacement parts that can be installed rather easily, following the procedures outlined regarding proper valve dismantling and reinstallation.

If other components are impacted, like fittings or gaskets, assessments must be made. It may be necessary to procure replacement parts or repair existing components. Engaging with professional services may also be advisable if the damage is extensive or if one is unsure about appropriate corrective measures.

The Enduring Importance of Proper Dismantling

Dismantling the porcelain core valve for solar installation stands as a fundamental skill that binds together numerous critical disciplines. Familiarity and expertise in this area ensure that systems operate with efficiency and reliability. Through meticulous preparation, an understanding of the valve structure, safe dismantling methods, and the correct approach to reinstallation, practitioners can contribute positively to the realm of solar operations.

Moreover, utilizing the insights gained from tackling intricate problems positions individuals to handle forthcoming challenges with confidence. The knowledge acquired through these processes not only applies to the specific task at hand but can touch on broader themes of technical proficiency and continual learning. Likewise, understanding the mechanics of how systems operate fuels the push towards sustainable energy solutions, reshaping the landscape of modern infrastructure for future generations.

Ultimately, those engaging in such tasks should regularly refresh their knowledge and adapt to evolving technologies and methodologies within the solar industry. As advancements continue to shape the dynamics of energy consumption and water management, practitioners who embrace these changes will be well-equipped for the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-porcelain-core-valve-for-solar-installation/