Cleaning solar energy systems involves maintaining the components responsible for harnessing solar power. Proper maintenance ensures efficient operation, prolongs the lifespan of the equipment, and ultimately enhances energy production. To dismantle the pipes for cleaning effectively, 1. safety precautions are critical, 2. understanding the system’s layout is essential, 3. proper tools must be utilized, 4. reassembly requires careful attention to detail. Among these points, safety precautions warrant detailed attention, as they protect both the individual performing the task and the integrity of the solar energy system. Without proper safety measures, individuals risk injury from electrical components, pressurized pipes, or falls when working at heights. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and harnesses can mitigate these risks effectively.

1. UNDERSTANDING THE SOLAR SYSTEM COMPONENTS

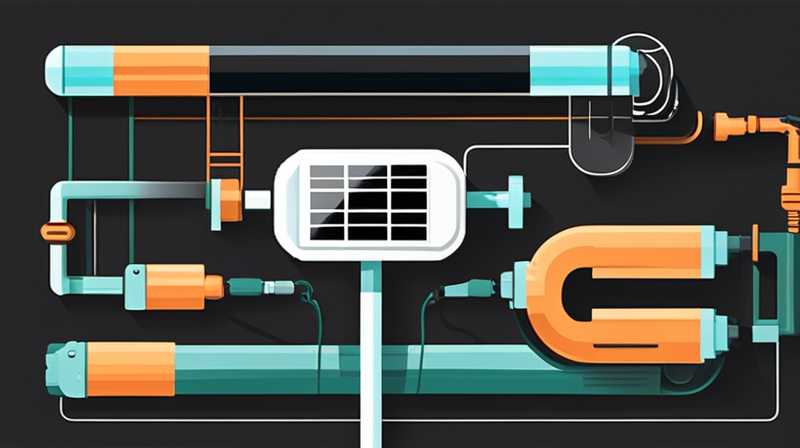

A comprehensive grasp of solar energy systems is necessary for effective maintenance and cleaning protocols. The components include solar panels, inverters, batteries, and pipes that carry fluids for cooling or heat exchange. Understanding the function of each part allows for more informed dismantling and reassembly, minimizing the potential for damage.

When approaching the dismantling process, specific attention must be directed toward the hydraulic elements responsible for circulating fluids in solar thermal systems. Shock and pressure management are vital, as neglecting these aspects during disassembly may lead to leaks or component failure. Therefore, recognizing how pipes interconnect and the role they play in the overall system is essential.

2. SAFETY MEASURES BEFORE DISMANTLING

Before initiating the dismantling process, establishing a safe working environment is paramount. Precautions should include shutting down the solar energy system entirely, thereby avoiding electrical hazards. Utilizing appropriate PPE safeguards against potential dangers such as falling debris or accidental exposure to fluids.

In addition to personal safety, ensuring proper ventilation while dismantling pipes is crucial. The release of trapped gases or thermal fluids poses risks, necessitating an environment that allows for such emissions to dissipate safely. Engaging a knowledgeable assistant can provide support and an additional safety layer during this intricate procedure. Having a reliable communication method during the process further enhances safety by ensuring that help is readily available if needed.

3. TOOLS REQUIRED FOR DISMANTLING PIPES

Equipping oneself with the right tools significantly impacts the efficiency and effectiveness of dismantling tasks. Essential tools may include wrenches, screwdrivers, pipe cutters, and pliers. Each tool plays a specific role, making the task smoother while minimizing damage to components.

Using high-quality tools is also fundamental in avoiding stripping screws or damaging pipes. Investing in both a comprehensive set and specialized tools enhances effectiveness. For instance, a pipe wrench can secure and leverage pipes efficiently for unscrewing threaded joints. It’s important not to overlook smaller components, such as seals and gaskets, which may require a specialty tool for removal without causing additional wear to the surrounding parts.

4. DETAILED DISMANTLING PROCESS

Once safety measures are in place and appropriate tools gathered, the next phase involves the systematic approach to dismantling the pipes. Begin by examining the entire system layout and identifying the different connection points for the pipes. This visual assessment aids in determining the sequence of disassembly, allowing for structured removal of each component.

With a plan established, start with loosening the closest connections to the main structure and work outward. Utilizing a pipe cutter, when appropriate, may be necessary for removing pipes that are stuck or corroded. Extreme caution must be exercised during this step, as excessive force may damage adjacent components. Handling each piece with care fosters an easier reassembly phase later.

5. CLEANING THE DISMANTLED COMPONENTS

Following successful dismantling, cleaning the pipes and related components is critical for optimal system performance. A range of cleaning agents is suitable for dissolving grease, dirt, and other contaminants. Depending on the material of the pipes, specific cleaners may be more effective than others.

Additionally, brushes and scrapers might be necessary for stubborn particles that require physical removal. However, care must be taken not to scratch or mar the pipe surfaces, which could interfere with fluid flow. After thoroughly cleaning, rinsing components with warm water will eliminate any residue from cleaning agents, ensuring that parts are ready for reinstallation.

6. REASSEMBLY OF THE SYSTEM

The reassembly phase is just as crucial as the dismantling process. Carefully adhering to the layout established prior ensures all parts are accounted for and reattached correctly. Initiating this step systematically prevents confusion and errors, such as improperly secured connections that could lead to leaks.

A meticulous approach involves replacing any worn-out seals or gaskets to prevent future leaks. Utilizing a torque wrench to apply the recommended specifications for each connection is advisable. This step minimizes the risk of over-tightening, which could damage components, or under-tightening, leading to leaks. After reassembly, conducting a thorough inspection of all connections and components guarantees that the system operates efficiently.

7. TESTING AND VERIFICATION POST-CLEANING

Once reassembly is complete, testing the solar energy system becomes essential to ensure everything operates as intended. Begin by restoring power to the system and monitoring its functioning closely. Observing flow rates and assessing for any signs of leakage during this phase provides confidence in the reassembly.

Should there be issues, revisiting each connection point for accuracy is crucial. Understanding how various system components interact aids in diagnosing potential issues that may arise during operation. Incorporating regular post-cleaning checks into maintenance protocols fosters long-term system efficiency.

FAQs

WHAT ARE THE SIGNS THAT THE SOLAR PIPES NEED CLEANING?

Several indicators suggest that solar pipes require attention. 1. Significant drop in energy output, often reflective of obstructions or deposits within the tubing. 2. Visible dirt or buildup on the pipe exterior can suggest that it is time for a thorough cleaning. Blockages can significantly impede fluid flow, hindering the overall efficiency of the solar energy system.

Another consideration is 3. Unusual noises emanating from the system. Sounds such as gurgling or banging can indicate that air pockets form in the pipes, likely due to blockages. Maintaining a regular cleaning schedule based on these indicators can prolong component lifespan and optimize overall system operation.

HOW OFTEN SHOULD SOLAR PIPES BE CLEANED?

The frequency of cleaning solar pipes largely depends on environmental factors and system usage. In regions with high dust levels or significant pollutant exposure, a quarterly cleaning schedule may be optimal. Conversely, areas with minimal contamination can allow for a biannual cleaning approach, balancing maintenance needs with operational efficiency.

Regular inspections alongside cleaning schedules are beneficial, as they help determine optimal frequency based on actual performance and visible conditions. Consistent upkeep not only enhances the system’s productivity but also reduces the likelihood of costly repairs or component failures due to neglect.

CAN I CLEAN SOLAR PIPES MYSELF OR HIRE A PROFESSIONAL?

The decision to clean solar pipes independently or hire a professional hinges on individual skill levels and comfort with working on such systems. For those with DIY experience, performing cleaning tasks can be a cost-effective choice, as it not only saves money but also provides a better understanding of the system’s workings.

However, individuals inexperienced with plumbing or electrical systems should consider engaging a qualified technician. Professionals possess the necessary skills, tools, and experience to ensure the task is carried out safely and effectively. Furthermore, they may identify potential issues that a novice may overlook. Overall, the choice should take into account not only skill levels but also the complex nature of the solar energy system.

Cleaning the pipes integral to solar energy systems is a vital maintenance task that significantly contributes to overall efficiency and longevity. Prioritizing safety, employing the right tools, and systematically dismantling the components are fundamental to a successful outcome. Emphasizing careful cleaning protocols ensures that every part is in prime condition for optimal performance. Maintenance does not end after cleaning; post-cleaning inspections and testing guarantee any problems are addressed before they escalate. Regular upkeep and informed decision-making regarding professional services foster both efficiency and safety in solar energy systems, enhancing their capabilities and lifespan while reflecting responsible ownership.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-pipes-to-clean-the-solar-energy/