The process of dismantling the double-sided solar panel casing involves several steps and considerations that must be understood thoroughly for effective execution. 1. Preparation of necessary tools and materials, 2. Understanding safety precautions, 3. Identifying assembly components, 4. Methodical disassembly approach. Preparation of necessary tools and materials is critical as it ensures efficiency and safety when dealing with potentially fragile components. This process might involve lay-outting screwdrivers, safety glasses, and a clean workspace. Understanding safety precautions is imperative because solar panels can contain delicate materials and electrical components that, if improperly handled, may result in damage or injury. Proper knowledge of each component involved in the assembly aids in minimizing risks as well. Identifying assembly components involves distinguishing between the layers of the casing and any adhering parts that could complicate the dismantling process. Finally, a methodical disassembly approach ensures that all steps are executed in a logical order, preventing confusion and ensuring the reassembly of the components (if necessary) can be done correctly.

1. PREPARATION OF NECESSARY TOOLS AND MATERIALS

To embark on the task of dismantling a double-sided solar panel casing, assembling the right tools and materials is non-negotiable. Tools commonly required include a variety of screwdrivers, both flat-head and Phillips, needle-nose pliers, and ideally, a torque wrench. The exact specifications may vary depending on the design and manufacturer of the solar panels in question. Additionally, having a multimeter handy to check connections can assist in preventing any shocks or electrical malfunctions during the dismantling process.

Besides tools, establishing a work area that is clean and organized is equally crucial. A reflective work surface will help ensure that any small components do not get lost during the dismantling process. Proper lighting is essential as well, as darker environments may lead to mistakes being made while servicing delicate parts. This preparation stage lays the groundwork for a successful operation and eliminates potential interruptions or complications that could arise from lacking essential tools or a suitable workspace.

2. UNDERSTANDING SAFETY PRECAUTIONS

Engaging with solar panels necessitates a sound comprehension of safety protocols. Solar panels comprise several sensitive components, both electrical and physical, necessitating precautions that ensure safety and prevent damage. Prior to dismantling, it is vital to cut off any power source feeding into the panels. For grid-tied systems, disconnection from the inverter is a key consideration, as live circuits pose risks of electrical shocks. For off-grid systems, ensure the disconnect switch is lifted or the battery is turned off.

The use of personal protective equipment (PPE) cannot be overstated. Gloves should always be worn to guard against accidental cuts or electrical hazards, while goggles can protect the eyes from any debris or shards that may break off during the dismantling process. A sturdy pair of shoes should be worn to protect against dropping tools or components. Understanding the type of materials that the casing is composed of (usually aluminum, glass, or polymer) can also help in preparing adequately for the dismantling operation. Creating a safe and conscious environment is fundamental to ensuring a successful and injury-free dismantling process.

3. IDENTIFYING ASSEMBLY COMPONENTS

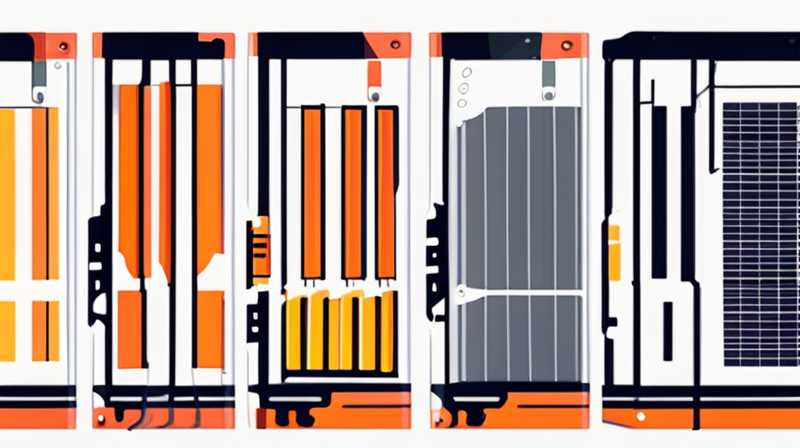

Dismantling the double-sided solar panel casing requires a keen understanding of the various assembly components intertwined within the structure. A typical double-sided solar panel unit consists of an encapsulated cell layer, a protective back sheet, front glass, and, depending on the model, space for electrical connectors. Identifying each of these components accurately is essential to prevent accidental damage during disassembly. The solar cells are often sandwiched between two layers of protective material, with possible adhesive layers that may require careful handling during disassembly.

Moreover, understanding how these components are attached is vital for an efficient dismantling process. Many panels utilize screws or tabs to secure the edges, while some may also use adhesives that solidify over time. Recognizing the type of fasteners involved helps in selecting the correct tools for removal. For example, hex screws may require specific bits, while clips or tabs may need careful prying to avoid breakage. Noting where each component fits within the casing will also assist reintegration or proper disposal of materials once dismantling is complete.

4. METHODICAL DISASSEMBLY APPROACH

An effective approach to dismantling involves a methodical and step-by-step procedure. Starting from the perimeter of the panel, one should systematically dismantle connectors and screws. By making a visual record of the positioning of each component, repair work or reassembly becomes simpler. It is often wise to travel in a clockwise or counter-clockwise direction to ensure that no parts are overlooked. Prudent organization of screws and connectors into labeled containers adds to the disassembly process, preventing confusion when attempting to put parts back together.

Following the perimeter dismantling, turn attention to any internal components that require removal. Utilize the multimeter to verify the lack of current in the solar cells, ensuring safety is maintained while handling the individual parts. The careful extraction of the solar cells, even if they are damaged, should be undertaken with precision to prevent breaking the delicate material even further. Clarity and logical sequencing ensure that the disassembly process is handled with both care and expertise.

5. REASSEMBLY OR DISPOSAL OF COMPONENTS

After disassembly, decisions regarding reassembly or disposal of components must be made. If the casing is to be reassembled, all parts should be inspected for damage or wear. Cleaning any debris or dust from internal components removes contaminants that can affect performance. Ensure that the seals and gaskets are intact, as these are vital for maintaining efficiency when reassembling.

In cases where certain components are deemed unusable, understanding local regulations about solar panel disposal is crucial. Often, specific materials such as glass and metals can be recycled. Finding a competent recycling facility ensures that environmentally hazardous substances within the solar cell do not enter landfills. Furthermore, individuals should consult with the manufacturer or local waste authorities about the proper methods for the disposal of solar panels to guarantee compliance with environmental standards. Educating oneself about these processes ultimately contributes to responsible and sustainable practices in solar technology management.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE REQUIRED FOR DISMANTLING A DOUBLE-SIDED SOLAR PANEL?

A variety of tools is imperative for the disassembly of a double-sided solar panel. Primarily, a collection of screwdrivers featuring both flat-head and Phillips tips is necessary, enabling the removal of various screws that may secure the casing. Needle-nose pliers can assist in pulling out wires or connectors that might be tightly held. Additionally, using a torque wrench may be beneficial for any secured components under significant tension. A multimeter is also recommended to monitor electrical connections, especially for checking that any currently flowing through the unit is disconnected. Proper PPE is critical for personal protection against electric shock or cuts. Gloves minimize hand injuries, goggles shield the eyes from debris, and sturdy footwear protects feet from falling tools or components. Ensuring all appropriate tools and protective gear is in place prior to commencement will create a safer and more effective dismantling experience.

ARE THERE ANY SAFETY CONCERNS WHEN DISMANTLING SOLAR PANELS?

Indeed, multiple safety concerns arise when dismantling solar panels. The structural components are often fragile, subject to shattering if excessive force is utilized during disassembly. It is paramount to ensure no electrical current runs through the panel before commencing work. For grid-tied models, deactivating the inverter is essential, while off-grid modules require disabling battery supply. Wearing safety goggles and gloves is mandatory; while engaging with the panel, accidents occur, and personal protective equipment ultimately safeguards users from potential hazards. Another consideration includes the handling of sharp components, particularly when glass or metal sections are involved. Ensuring that the working area is organized and well-lit alleviates risks associated with tools and components going astray. Ultimately, safeguarding oneself from injuries while preserving the integrity of the solar panel installation is of utmost importance in the disassembly process.

HOW CAN I DISPOSE OF OR RECYCLE SOLAR PANEL COMPONENTS RESPONSIBLY?

Responsible disposal or recycling of solar panel components can be achieved through understanding local waste management regulations. Many regions provide specialized recycling programs for solar panels due to the materials involved, such as rare metals and glass. Initially, separating components based on material type—glass, metals, and electronics—streamlines the recycling process. Contacting local municipal waste facilities can offer details on appropriate disposal methods. Additionally, many manufacturers offer take-back programs to ensure environmentally-friendly disposal techniques are employed. Finding facilities that can recycle lithium or cadmium—common materials found in solar cells—is vitally important, as mishandling can lead to toxicity in the environment. Engaging with community programs dedicated to clean energy initiatives can also provide information and guidance on the sustainable management of solar panel waste. Ultimately, responsible action in recycling or disposal contributes positively towards environmental conservation and adherence to regulations.

A THOUGHTFUL APPROACH TO DISMANTLING SOLAR PANELS

In undertaking the dismantling exercise of double-sided solar panels, comprehending the underlying intricacies and nuances enhances performance and ensures optimal outcomes. In the initial stages, advancing towards securing the appropriate tools, creating a safe work environment, and drafting a thorough understanding of panel architecture and assembly remains crucial. This level of preparedness establishes a foundation rooted in safety and efficiency while carrying out the physical tasks at hand. The multi-faceted nature of dealing with electrical and mechanical components necessitates astute attention to detail; thus, the methodologies employed should promote organization, clarity, and sound decision-making, adding to the overall success of the operation.

Harnessing the opportunity to reassemble or responsibly dispose of utilized components encourages environmentally-conscious practices that resonate widely in today’s sustainability landscape. The efforts toward disassembly not only serve practical needs but also ignite a broader dialogue about renewable energy management and ethical resource utilization. A commitment to these principles now paves the way for advancements in renewable energy systems and supports the transition to an eco-friendly future. Ultimately, embracing diligence, respect for materials, and a proactive mindset enriches the entire process, opening avenues for innovation and responsible stewardship in the realm of solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-the-double-sided-solar-panel-casing/