Dismantling solar panels involves a systematic approach to ensure safety and efficiency during the process. 1. Tools and Equipment Required, 2. Safety Precautions, 3. Step-by-Step Process, 4. Understanding the Materials, 5. Copper Components. The most noteworthy aspect of deconstructing solar panels is the presence of valuable metals, specifically copper, which plays a significant role in conductivity and energy transfer within the panel. This article will explore the necessary procedures and insights related to the dismantling of solar panels, emphasizing the importance of copper within their structure.

1. TOOLS AND EQUIPMENT REQUIRED

Carrying out the dismantling task necessitates a range of tools tailored for efficiency and safety. The first step entails gathering essential tools, which often include a multimeter, insulated screwdrivers, socket wrenches, and safety gear such as gloves and goggles. These instruments not only aid in disassembling the panels but also ensure that the technician is equipped to handle potential hazards.

Using a multimeter provides the ability to measure electrical outputs, ensuring that the panels are completely de-energized before any dismantling begins. Insulated screwdrivers are critical when handling any electrical apparatus, reducing the risk of shock. Moreover, having proper protection such as gloves and goggles allows for safe handling of potentially hazardous materials. Safety should always remain a priority when tackling such projects.

The efficiency of the dismantling operation is greatly enhanced by organizing and labeling the tools. Each component of the solar panel must be dealt with meticulously, making the right tools essential for preserving it. A well-prepared workspace minimizes the risk of accidents and allows for a smoother workflow, ultimately leading to better results in dismantling the solar panels effectively.

2. SAFETY PRECAUTIONS

Engaging in the dismantling of solar panels can pose unique risks, and thus, safety protocols are imperative. Prior to beginning the process, one must ensure that the panels have been disconnected from any power source. In order to mitigate electrical hazards, it is essential to verify the absence of voltage. Use a multimeter to ensure that there is no residual energy stored in the panels, as this greatly reduces the risk of electric shock during dismantlement.

Working with heights is another potential danger when dealing with mounted solar panels. Adopting proper ladder safety practices protects the individual from falls or fatalities. Ensuring the ladder is stable, maintained, and positioned against a solid structure is crucial. Additionally, working in pairs or having someone on standby can provide immediate assistance in case of an emergency.

Furthermore, the handling of broken glass from the panels is a major concern. Utilizing protective clothing, including closed-toed shoes, long sleeves, and gloves, helps prevent injuries during the process of dismantling. Glass shards can be sharp, necessitating careful handling to avoid cuts and subsequent infections.

In summary, laying emphasis on safety measures such as confirming the panels are de-energized, appropriately using ladders, and protecting oneself from sharp glass ensures a dismantling process that prioritizes the technician’s well-being throughout the operation.

3. STEP-BY-STEP PROCESS

The dismantling operation can be simplified into a series of organized actions. This structured methodology ensures that each phase of the process is thoroughly covered, significantly reducing the chances of overlooking crucial steps.

Begin the dismantling process by removing the solar panels from their mounts. Depending on the installation type, this may involve unscrewing or unclipping the panels. Utilizing socket wrenches and insulated screwdrivers, carefully loosen any bolts or screws holding the panels in place. This step should be done with caution, ensuring that the panels are securely supported while removing them. Handling panels gently minimizes the risk of breaking them and potentially releasing harmful gases.

Once the panels are detached, the next phase is to dismantle the mounting brackets. Many solar panel systems use aluminum brackets for support, offering opportunities for recycling. Aluminum is a widely recycled material, and you might find local facilities that accept these components. Carefully unscrew any remaining fixtures and gradually dismantle the bracket system, keeping in mind the structural integrity of the remaining components.

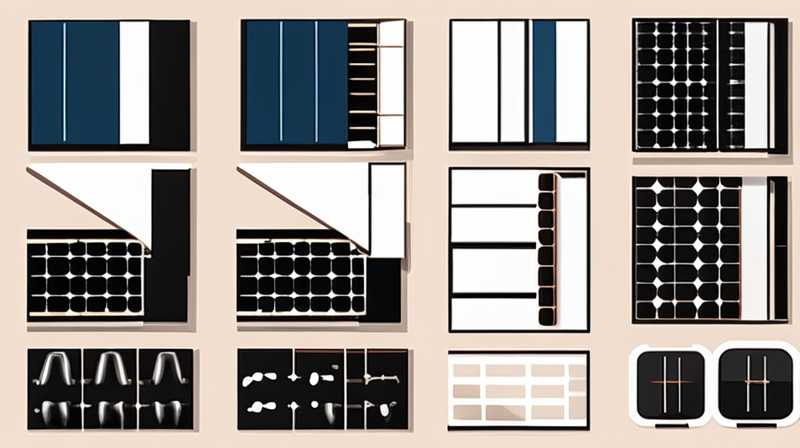

Following the disassembly of mounting brackets, it is essential to carefully break down the solar panel layers for further recycling and copper extraction. Solar panels are typically composed of tempered glass, an ethylene-vinyl acetate (EVA) encapsulant, a silicon photovoltaic cell, and a backsheet made from polyvinyl fluoride (PVF). Each layer must be treated with care.

Using a glass cutter, you may slice through the edges of the solar panels, ensuring safety precautions are still in place. Breaking the layers down individually minimizes damage and maximizes the possibility of recovering aluminum, glass, silicon cells, and copper components. The internal copper wiring will be found within the junction box located at the rear of the panel.

Finally, ensure that all components are stored properly. Scrap metals should be placed in designated bins to simplify future recycling or sale. Keeping each component organized helps maintain a clear understanding of what materials can be repurposed.

4. UNDERSTANDING THE MATERIALS

The composition of solar panels greatly influences their dismantling process, particularly in terms of recycling and recovery of valuable materials. Understanding the materials not only helps in precise dismantling but also enables individuals or entities to strategize on eco-friendly disposal or repurposing alternatives.

The primary element found in solar panels is silicon, which is key for its electrical properties. Silicon cells often undergo various recycling processes to reclaim the original materials. It is essential to handle silicon cells with care during disassembly, ensuring a sustainable approach to recycling. Though recycling silicon cells can often present challenges, modern advancements in technology allow for more efficient reclamation methods, promoting sustainability and reducing ecological footprints.

Then there comes aluminum, which is primarily utilized for the mounting structures. Aluminum is valuable in the recycling market due to its relatively low cost of recovery and widespread applicability across various industries. Should the mounts be dismantled carefully, they can significantly reduce landfill contributions while generating potential revenue through sales to scrap yards.

Besides silicon and aluminum, the presence of copper wiring within the solar panel junction box should be highlighted. Copper is essential for electrical conductivity, and its recovery can certainly benefit environmentally conscious practices. By extracting copper from the panels, individuals contribute to a more circular economy, promoting sustainability and responsible resource management.

Additionally, attention must be paid to the glass and encapsulants used in solar panels. Tempered glass may seem unrecyclable, yet it remains a recyclable material, as it can be repurposed into aggregates for concrete or new glass production. EVA encapsulants generally present more disposal challenges; however, new technologies are being developed to address how these materials can safely be processed.

Structured understanding of these materials fosters a comprehensive approach to solar panel dismantling, ultimately encouraging practices that promote efficient recycling avenues while minimizing environmental impact.

5. COPPER COMPONENTS

The topic of copper in solar panels is substantial, as it significantly contributes to their functionality and value. The value of copper as a material cannot be overstated due to its high conductivity properties. Its presence allows for the efficient transfer of electricity generated by the solar cells to the inverter and eventually to the electrical grid.

During the dismantling process, attention must be paid to the retrieval of copper wiring located in the junction box at the rear of the panels. These wires are typically insulated and connected to the solar cells. Their careful extraction is essential as they can provide a revenue stream through recycling or repurposing. Even small amounts of copper can accumulate significant value, encouraging meticulous recovery practices during the dismantling process.

Furthermore, it is pivotal to note that the impact of copper recovery reaches beyond economic benefits, contributing to environmental sustainability. As a finite resource, recycling copper reduces the demand for new copper mining, which is notorious for numerous environmental consequences. By reclaiming copper from old solar panels, individuals and businesses participate in reducing the carbon footprint associated with primary copper production.

Promoting the understanding of copper’s role within solar panels can lead to better practices in the dismantling process. Encouraging better recovery methods and advocating for the value of this material allows for improved environmental policies while generating a sustainable outcome with potential economic benefits.

FREQUENTLY ASKED QUESTIONS

HOW SAFE IS IT TO DISMANTLE SOLAR PANELS YOURSELF?

Undertaking the task of dismantling solar panels independently carries inherent risks; however, with proper preparation and precautions, safety can be significantly enhanced. Before proceeding with any disassembly, it is paramount to disconnect the system from its power source completely, ensuring that no electricity flows through the panels. Utilizing insulated tools and wearing protective gear like gloves, goggles, and sturdy footwear can shield individuals from hazards.

Moreover, it is advisable to work with a partner who can assist during the process, especially when handling the panels at height. Ensuring the workspace is clear of clutter and utilizing stable ladders will further mitigate potential accidents. However, if one lacks the necessary experience or comfort with electrical systems, consulting with professionals or hiring skilled labor might be the best path. Experts possess knowledge of local regulations and equipment handling, creating a safer dismantling environment.

Overall, while personal dismantling can be done safely, it requires a strong understanding of risk factors and proper safeguards. Knowledge of correct procedures and unwavering adherence to safety standards can lead to an effective and protected dismantling experience.

WHAT WILL HAPPEN TO THE SOLAR PANEL MATERIALS AFTER DISMANTLING?

Post-dismantling, the materials from solar panels embark on an important journey toward sustainability and recycling. After the extraction of components, such as aluminum, silicon, and glass, these materials can be sent to specialized facilities for processing and reclamation. Aluminum, for example, is one of the most recycled metals, as its recycling process consumes significantly less energy compared to primary production.

Silicon cells can be repurposed for various applications within the solar industry; however, the recycling process can be more involved due to the need to purify the silicon further. Modern advancements in technology continuously evolve to improve the efficiency of silicon recycling, allowing for cleaner production methods that lessen environmental impacts.

Additionally, the glass from solar panels can often be recycled into new glass products or aggregates for construction. Proper sorting and processing at recycling facilities are essential to ensure materials are effectively reclaimed.

In various instances, copper wiring can be sold at scrap yards, providing potential revenue for those who dismantle solar panels. Such selling creates an opportunity to generate income while encouraging resource recovery. As a whole, the fate of materials after dismantling follows a path toward sustainable practices, contributing to environmental preservation and minimizing landfill contributions.

WHY IS COPPER CONSIDERED VALUABLE IN SOLAR PANELS?

Copper’s value in solar panels stems primarily from its remarkable conductive properties, allowing it to effectively transport electricity from the solar cells to the inverter. Without copper, the efficiency of energy transfer within the system would diminish significantly. With the increasing reliance on renewable energy sources, copper’s role has become more essential, making it highly sought after in the energy market.

Furthermore, as the global demand for clean energy escalates, the need for copper in various technologies continues to rise. Industries ranging from electric vehicles to energy storage solutions all utilize this excellent conductor, creating a ripple effect in its value. The challenge of accessing new copper sources through mining operations leads to increased market prices, lending further significance to its recovery from old solar panels.

The copper market’s fluctuating prices also feed into its value for recycling. The challenge lies in balancing between the demand for new copper and the environmental impacts associated with extraction. By reclaiming copper from existing solar panels, consumers can support sustainability while gaining monetary returns through recycling programs. Therefore, copper not only represents functionality in solar technology but also embodies a broader narrative of responsible resource management and economic opportunity.

In summation, dismantling solar panels incorporates a systematic approach, focusing on efficiency and safety throughout the process. Several vital components, including tools required for disassembly, safety precautions, step-by-step guidelines, and a thorough understanding of materials, contribute to successful solar panel dismantling. The presence of copper enhances the value of the panels, as it plays a key role in energy transfer while also representing a crucial resource for recycling. The growing demand for renewable energy technology emphasizes the need for responsible dismantling practices that promote sustainability while allowing for economic benefits. Thus, understanding these factors will facilitate better management of solar energy systems as they reach the end of their operational lives, providing valuable insights into the recycling and recovery measures needed to embrace a circular economy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-solar-panel-is-there-copper-inside/