To effectively dismantle solar cooling pipes, it requires a thorough understanding of the components and the specific procedures necessary to ensure safety and efficiency. 1. Preparation is critical; 2. Safety precautions cannot be overlooked; 3. Methodical disassembly is essential; 4. Cleanliness and proper disposal of materials are crucial. In preparation, it is necessary to assess the system and gather appropriate tools, ensuring that isolation of the system from power sources and fluid lines is executed effectively. Safety measures must be observed, emphasizing personal protective equipment (PPE) to prevent injuries. A systematic approach to the disassembly of pipes is required, focusing on methods for removing connections without damaging the fittings or other components. Finally, attention to cleanliness and proper disposal will assist in maintaining an organized workspace and minimizing environmental impact.

1. UNDERSTANDING SOLAR COOLING SYSTEMS

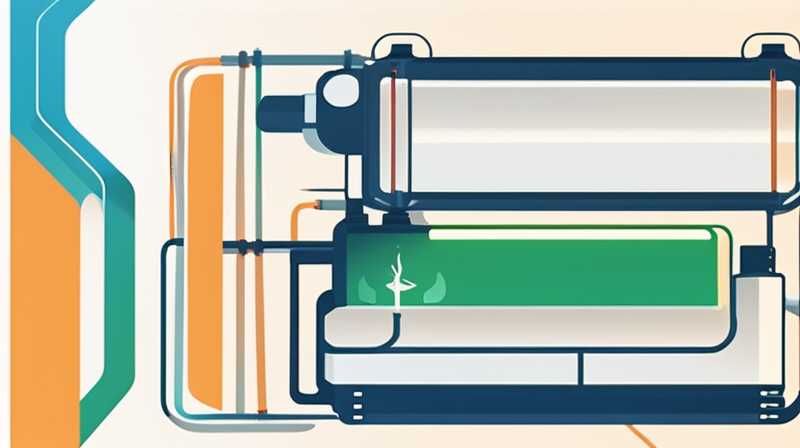

Solar cooling systems harness solar energy to provide cooling through various methods, such as absorption or adsorption refrigeration cycles. They typically include components like solar collectors, chillers, and distribution systems, which utilize pipes to transport the cooling medium. In dismantling these systems, a clear comprehension of how each component functions and its interconnectedness is imperative. These systems are often installed in residential and commercial buildings, aimed at reducing energy costs while promoting sustainability.

In order to dismantle solar cooling pipes successfully, it is essential to have a foundational knowledge of the materials used in piping, such as copper, PEX, or PVC. Each type of material has specific properties that affect both the dismantling process and the tools required. For instance, copper piping necessitates the use of cutting tools or joint disassembly techniques, while PEX can be cut with simple tubing cutters. Understanding the different materials allows for a more efficient and effective dismantling process.

2. PREPARATORY STEPS FOR DISASSEMBLY

Before embarking on the disassembly process, a thorough inspection of the system must be conducted. This inspection should include checking for any leaks or damages that may pose a risk during the dismantling process. Documentation of the current configuration should be prioritized. Taking photographs or notes will ensure that the system can be reassembled correctly if necessary.

Gathering appropriate tools is another critical preparatory step. Essential tools may include wrenches, pipe cutters, pliers, and safety glasses. Having these tools on hand not only expedites the process but also minimizes the risk of improvisation, which can lead to errors or accidents. Furthermore, it is wise to have protective gear, such as gloves and masks, to safeguard against any potential hazards that could arise from dust or debris during disassembly.

3. IMPLEMENTING SAFETY PRECAUTIONS

Safety cannot be emphasized enough when dismantling solar cooling pipes. The first course of action is to disconnect the system from any power source, ensuring that electricity is not a potential hazard. Additionally, draining the fluid from the system is crucial to prevent spills and exposure during the dismantling process. Ensuring that the cooling medium is safely contained and disposed of is not only prudent but often a legal requirement due to environmental regulations.

Wearing appropriate PPE is essential for any individual undertaking the dismantling process. This includes safety goggles to protect the eyes from dust and debris, gloves to prevent cuts and scrapes, and a face mask if silica, dust, or other particulates are present. Before beginning, a risk assessment of the work area is advisable to identify any potential hazards, allowing for proactive measures to be taken to ensure safety throughout the process.

4. DETAILED DISASSEMBLY PROCESS

When it comes to the actual dismantling of solar cooling pipes, a methodical and well-planned approach should be adopted. Start by examining all joints and fittings to determine how they are connected. Using appropriate tools, such as pipe wrenches, to loosen and remove fittings is recommended. In many cases, soldered joints will require heat to be applied, while threaded connections generally can be unscrewed by hand.

For any sections of piping that are fused together, the implementation of a pipe cutter is prudent. This helps prevent unnecessary damage to adjacent pipes and components. Once the pipes are free, carefully label each segment, documenting its order and orientation. This practice fosters an organized dismantling process, allowing for precise reassembly in the future.

5. CLEANLINESS AND DISPOSAL OF MATERIALS

Post-disassembly, maintaining cleanliness is paramount. Ensuring that all debris and leftover materials are properly disposed of is crucial at this stage. Collect all used parts and clean up the workspace, as residual materials can pose trip hazards or cause confusion during subsequent procedures. It is essential to check local regulations for proper disposal methods, particularly regarding any hazardous materials, such as refrigerants.

In addition to proper disposal of leftover materials, it is advisable to clean the remaining components of the system to ensure they remain in optimal condition for future use. This may involve rinsing pipes, cleaning fittings, and eliminating any contaminants. Organizing the sorted components will simplify any potential reinstallation process and aid in maintaining a professional work environment.

FAQS

WHAT EQUIPMENT IS NEEDED FOR DISMANTLING SOLAR COOLING PIPES?

The dismantling process of solar cooling pipes requires a variety of tools designed for precision and safety. Essential equipment includes wrenches, pipe cutters, adjustable pliers, and screwdrivers. Additionally, it is prudent to have safety gear such as gloves, goggles, and masks to prevent injury during the operation. Using the right tools ensures that the job is completed efficiently and minimizes damage to the system’s components.

Before beginning the dismantling process, assess the specific pipe materials present within the system, as the type may dictate the required tools. For example, cutting copper pipes necessitates a different tool than PEX. Understanding these nuances allows for a smoother and more structured approach to dismantling solar cooling pipes, ultimately saving time and enhancing safety.

HOW CAN I MINIMIZE RISK DURING DISASSEMBLY?

To minimize risk during the dismantling of solar cooling pipes, it is vital to adhere strictly to safety precautions and ensure a well-structured methodology. First, disconnect the system from any power sources; this eliminates the risk of electric shock. Next, draining the system of its cooling medium protects against spills that could pose hazards during dismantling.

Furthermore, wearing appropriate PPE is essential for protection against any potential injuries. Always maintain a tidy workspace and organize tools effectively, which minimizes the risk of accidents or injuries. Regularly reviewing safety procedures and conducting a thorough risk assessment of the work area will further ensure a safe dismantling operation while enhancing overall efficiency and safety.

WHAT SHOULD I DO IF A PIPE IS STUCK OR CANNOT BE REMOVED?

Encountering a stuck pipe during the dismantling process can be frustrating and challenging; however, there are several strategies to address the issue effectively. Start by applying a penetrating oil to the joint or fitting; allowing it to soak can break the bond and facilitate easier disassembly. Patience is key during this process, as too much force can lead to pipe damage or injuries.

If heat is applicable and safe, gently warming the pipe with a heat gun or propane torch can help loosen the connection. Always exercise caution when applying heat and avoid overheating any rubber or plastic components. Using a pipe wrench to grip the joint firmly may also assist in breaking the connection. Should all efforts fail, consulting with a professional may be prudent, as they often have access to specialized tools that can safely remove stubborn pipes.

In summary, the dismantling of solar cooling pipes involves a nuanced understanding of both the system’s components and methodologies required for safety and efficiency. A thorough preparation phase is critical; adhering to safety protocols is non-negotiable; employing effective disassembly techniques is vital; maintaining a clean and organized environment is essential. Taking the time to understand these components and following each step methodically will yield successful outcomes, whether for repairs, upgrades, or system replacements.

Performing the dismantling process requires intricately planning, and this guide provides a valuable framework for ensuring each stage is executed properly. Proper knowledge and preparation not only enhance the likelihood of a successful dismantling but also contribute to overall safety and efficiency within the operation. Remember, approaching this task with respect for the system’s design and functionality ensures long-term benefits and sustainability. Moreover, maintaining best practices for safety, cleanliness, and organization will pave the way for smoother transitions to future operations, reinforcing both personal and environmental responsibility.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-solar-cooling-pipes/