To effectively dismantle a solar wall-mounted boiler, one must follow a systematic approach. 1. Preparation is vital, ensuring safety measures are in place, such as turning off the power and disconnecting water supply. 2. Gather necessary tools, including wrenches, screwdrivers, and pliers. 3. Take detailed notes or photographs during disassembly for future reference. 4. Carefully remove each component in reverse order of installation, ensuring no damage occurs to surrounding structures or pipes. A meticulous process not only simplifies the task but also ensures a safer and more efficient dismantling experience. Proper knowledge and equipment can prevent accidents and ensure the successful removal of the boiler without compromising the existing plumbing or electrical systems.

1. UNDERSTANDING THE SOLAR WALL-MOUNTED BOILER

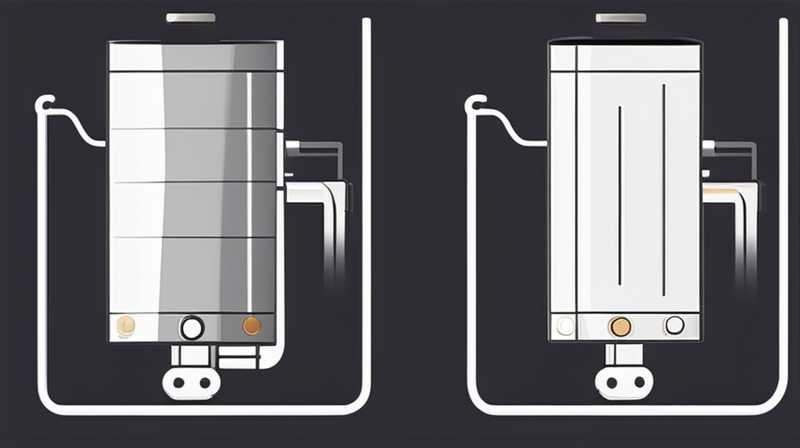

In recent years, solar wall-mounted boilers have gained prominence due to their energy efficiency and environmental benefits. These systems harness solar energy, converting it into heat for domestic water usage, making them a sustainable choice for many households. Their structure typically involves various components, including panels, storage tanks, and controls, each working harmoniously to optimize energy use. Understanding how these components interact is crucial when it comes time to dismantle the system.

A thorough comprehension of the system’s layout facilitates a more straightforward dismantling process. Every aspect, from the solar panels on the exterior to the internal plumbing connections, contributes to the boiler’s overall functionality. This knowledge will help ensure that when the time comes to remove these components, the task is accomplished in a methodical manner, thereby reducing the risk of damaging connected systems or structures.

2. SAFETY PRECAUTIONS

Before embarking on the dismantling journey, several safety protocols should be meticulously followed to safeguard the individuals involved as well as the surroundings. Significantly, the first step is to disconnect the power supply to the solar boiler, as electricity poses numerous hazards during the dismantling process. This should include turning off the circuit breaker that supplies power to the system. Ensuring that the system is entirely de-energized minimizes the risk of electric shock or equipment malfunction.

In addition to powering down the system, it’s also imperative to address the water supply. Turning off the water supply valves can prevent any accidental leaks or flooding during disassembly. For added precaution, draining the boiler of water will minimize the weight of the components being handled, thereby reducing strain and potential injury to the person handling the equipment. Wearing protective gear such as gloves, goggles, and hard hats is also recommended, especially when working with heavy machinery or sharp edges.

3. PREPARING FOR DISMANTLING

A successful dismantling begins with proper preparation, which can significantly streamline the entire process. Gathering requisite tools and materials is essential. Common tools might include various sizes of wrenches for bolts, screwdrivers for screws, and a utility knife for cutting any adhesive or insulation that may be present. Having an organized workspace with ample lighting will enable a clearer view of the components being removed and reduce the likelihood of losing small parts.

Before diving into the actual dismantling, taking notes or photographs of the boiler’s setup can be a game-changer. These records will serve as a guide for reinstallation or future maintenance, providing clarity on how each component fits together. Moreover, labeling components as they are removed can significantly simplify reassembly or disposal. Good organization enhances efficiency, allowing for a smoother transition from the operational state of the boiler to a dismantled one.

4. DISASSEMBLY PROCESS

Beginning with the dismantling process itself, it is essential to approach it methodically, tackling one section at a time to avoid becoming overwhelmed. Initially, addressing the solar panels, which are typically mounted on the wall or a roof, involves unscrewing them from their mounts. Care must be taken to stabilize them during removal to prevent falling or causing injury. This task may require assistance, as the panels can be bulky and cumbersome.

With the panels removed, attention can turn to the connected piping. Each pipe should be traced back to the boiler unit, ensuring that all necessary valves are closed to prevent spills. The usage of wrenches is critical at this stage, as removing tightly fitted connections might require significant force. It is advisable to have a container ready to catch any residual moisture that may leak from the pipes.

After all external connections have been successfully detached, the next step is to proceed to the internal components of the boiler itself. Carefully examining the manufacturer’s guidelines can provide assistance here, helping to identify any components that may vary in construction. For instance, many modern systems include intermediates and heat exchangers, and understanding how these fit together is crucial.

5. MANAGING THE DISASSEMBLED COMPONENTS

Once the dismantling is complete, there will be numerous components that need to be appropriately handled. Deciding whether to recycle, dispose of, or reuse the parts is an essential part of the process. Many local municipalities have specific regulations concerning hazardous materials, such as antifreeze or insulation. It will be beneficial to research local disposal rules to avoid potential penalties. This concern for environmental impact aligns with the sustainability principles promoted by using renewable energy sources such as solar power.

Additionally, organizing the removed components can mitigate future confusion or damage. Creating a system for sorting materials based on their type or usage will prove advantageous if components need to be stored for later dates or reused in other applications. Utilizing clear bins, labels, and a designated storage area is advisable for ensuring everything is accounted for and easy to locate.

FREQUENTLY ASKED QUESTIONS

HOW DO I KNOW IF MY SOLAR WALL-MOUNTED BOILER IS FUNCTIONING PROPERLY?

Determining the efficiency of a solar wall-mounted boiler involves several evaluations. Regular checks of system pressure, temperature settings, and the condition of solar panels can indicate performance issues. Ideally, the boiler should maintain consistent temperature outputs that align closely with specified settings. Inspecting for any leaks or corrosion within the piping can also signal potential problems. Maintenance activities, such as cleaning the solar panels and checking connections, are vital for optimal performance. Utilizing performance logs can help track efficiency over time and identify any drops in heating capabilities that suggest malfunctions.

CAN I DISMANTLE THE SYSTEM MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While many individuals are technically inclined and may feel comfortable dismantling their own systems, hiring a professional is often recommended. Professionals typically possess the requisite skills and experience to safely dismantle complex systems while minimizing risks, including accidental damage to components or injury. Moreover, certified technicians are usually familiar with local codes and regulations that must be adhered to during the dismantling process. This expertise can ultimately save time and prevent costly mistakes or hazards that an average homeowner might overlook. If unsure about any aspect of the disassembly, reaching out to a professional is generally the safest option.

WHAT EQUIPMENT IS REQUIRED FOR DISMANTLING A SOLAR WALL-MOUNTED BOILER?

Tools and equipment vary based on manufacturer and setup, but certain essentials are generally needed. Basic tools include a socket set for removing bolts, screwdrivers for screws, and a utility knife for cutting insulation or adhesives. Other necessities might feature adjustable wrenches for pipe fittings and pliers for gripping or bending components. For heavy or bulky parts like solar panels, perhaps a hoist or lift is warranted. Having containers and labels on hand for sorting and storing components post-disassembly also boosts efficiency. Careful planning in gathering the right equipment can alleviate frustrations during dismantling, ultimately resulting in a smoother overall process.

When considering the dismantling of a solar wall-mounted boiler, it is evident that careful planning and execution play pivotal roles. It is crucial to acknowledge the various steps and components involved to ensure safe and efficient completion. Attention to detail, including adherence to safety protocols and methodical disassembly, can greatly reduce the risks of injury or damage to surrounding structures. By emphasizing preparation, safety, and organization throughout the process, individuals can navigate the complexities of dismantling with confidence. As the world increasingly shifts toward alternative energy solutions, understanding how to manage these systems —including proper dismantling —becomes a necessary skill. Whether for personal projects, maintenance, or improvements, the knowledge gained from undertaking such tasks can lead to both immediate benefits and long-term sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-dismantle-a-solar-wall-mounted-boiler/