To disassemble a street light solar controller, one must follow a systematic approach involving specific tools and knowledge of the controller’s design. 1. Preparation is key, 2. Gathering the right tools, 3. Understanding the internal components, 4. Safety precautions are paramount. Each step is crucial for a successful disassembly without damaging the unit. The intricate design of these devices often includes circuit boards, solar input terminals, and battery management systems that require special handling. It is essential to ensure that the solar controller is powered off and disconnected from the solar panels and batteries prior to starting the disassembly. A detailed understanding of each component will assist in accurately documenting or repairing any parts as necessary.

1. PREPARATION IS KEY

Before embarking on the journey of disassembling a solar controller, adequate preparation is paramount. Understanding the overarching function of the solar controller sets the stage for the entire disassembly process. These devices manage the power generated by solar panels, ensuring proper battery charging while preventing overcharging and deep discharging. Not only does this function accentuate the necessity of careful handling, it also indicates the complexity involved in the controller’s internal architecture.

An essential part of preparation is securing a dedicated workspace. This area should be free of clutter and debris, providing ample room for both the disassembling process and the organization of components. Establishing a systematic arrangement for screws, circuit boards, and other components is crucial to avoid confusion during reassembly. Using small containers or labels can significantly reduce the likelihood of misplacing vital parts. Also, having a digital or printed service manual for the specific solar controller model will aid in understanding how components fit together and where they are located.

2. GATHERING THE RIGHT TOOLS

Acquiring the proper tools is another critical phase in the disassembly process. Tools often required for this task include a precision screwdriver set, a multimeter for testing, and, in some cases, soldering equipment if the controller has soldered connections. Each tool serves a distinct purpose; for instance, precision screwdrivers help navigate the compact confines of the controller housing, while a multimeter assists in diagnosing functionality prior to disassembly.

In addition to standard tools, it may also be helpful to have anti-static gloves and wrist straps. Given the sensitivity of the componentry involved, these items mitigate the risk of electrostatic discharge, which can damage delicate electronic parts. Furthermore, lighting is a significant aspect of the workspace, ensuring visibility of small components and intricate sections of the controller. A well-lit environment fosters accuracy and precision throughout the disassembly.

3. UNDERSTANDING THE INTERNAL COMPONENTS

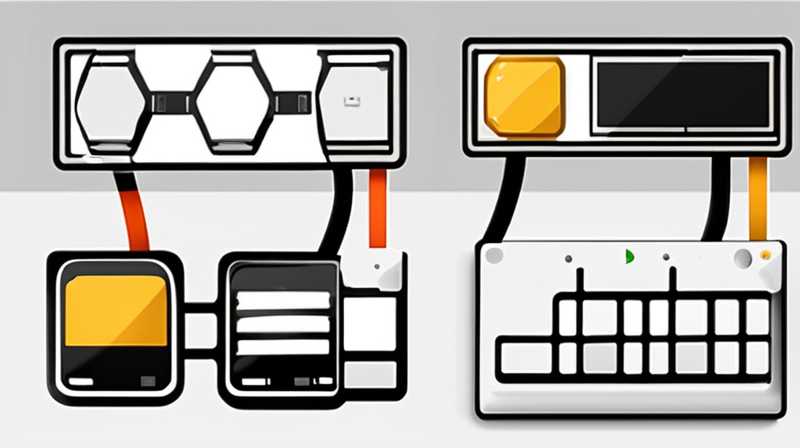

Once prepared, one must gain an intimate understanding of the internal components found within the controller. Most solar controllers consist of critical elements such as the microcontroller, voltage regulators, and various circuit paths that connect the solar panels to the battery storage system. Each component has a specific role and a unique connection to one another, emphasizing the need for caution during disassembly.

The microcontroller serves as the brain of the system, executing commands to optimize energy flow. In contrast, voltage regulators help maintain output levels, preventing damage from voltage spikes. A thorough understanding of these components enables a more effective disassembly process, as it allows one to identify which parts require careful handling and which can be safely removed without causing harm to the rest of the unit. Recognizing the interconnectedness of these components can assist in troubleshooting any issues that may arise during or after reassembly.

4. SAFETY PRECAUTIONS ARE PARAMOUNT

Prioritizing safety measures throughout the disassembly process cannot be overstated. Addressing electrical safety is vital, particularly since the controller interfaces with high voltages generated by solar panels. Ensuring that the controller is completely powered down and disconnected from all inputs is the first step. This includes discharging capacitors to prevent any accidental discharge that may injure the technician.

In addition to electrical safety, it is prudent to wear appropriate personal protective equipment (PPE). Consider wearing safety goggles to shield the eyes from small debris that may dislodge during disassembly. Gloves should be worn to protect against sharp edges or components that may cause cuts or scrapes. By adhering to safety precautions, the risk of injury and further equipment damage can be significantly reduced, leading to a more productive and secure working environment.

FAQs

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING A SOLAR CONTROLLER?

To disassemble a solar controller, specialized tools are essential. The core components typically include a precision screwdriver set tailored for fine electronics, a multimeter for testing components, and possibly a soldering iron to manage any soldered parts. Additional instruments such as pliers may be required for dealing with stubborn screws or clips. Having anti-static straps and gloves is also recommended to protect against electrostatic discharge. These tools contribute not only to the disassembly process but also aid in troubleshooting potential issues. Ensuring that tools are organized and readily available facilitates a smoother workflow and mitigates downtime.

HOW DO I IDENTIFY THE COMPONENTS INSIDE A SOLAR CONTROLLER?

Identifying the components within a solar controller can initially seem challenging, owing to the compact and intricate layout. Starting with the service manual is a wise approach, as it provides diagrams and descriptions of the components. The primary components include the microcontroller, various capacitors, voltage regulators, diodes, and connection terminals for solar panels and batteries. Each part fulfills a distinct role in managing energy input, processing commands, and maintaining battery health. Labeling components during disassembly is beneficial; it ensures that all pieces can be precisely re-installed and understood during reassembly. An understanding of the basic electrical principles that govern each component will enhance familiarity and facilitate the identification process.

WHAT COMMON ISSUES CAN ARISE DURING DISASSEMBLY?

Common issues encountered during the disassembly of a solar controller include damaged components, lost screws, and accidental short circuits. Physical damage can occur if excessive force is applied while removing parts, especially connectors and circuit boards. Additionally, smaller screws are often prone to being misplaced; thus, using containers or specialized trays can help manage these issues effectively. Furthermore, failing to power down and discharge components properly can lead to dangerous situations, risking short circuits. Documenting the disassembly process with photographs can also help track how components fit together, reducing the chances of errors during reassembly. Each challenge presents learning opportunities, allowing for better preparedness in future attempts.

The act of disassembling a street light solar controller demands a methodical approach, underscored by thorough preparation and adherence to safety protocols. By gathering the necessary tools, comprehending the components within, and employing essential safety measures, one can navigate this intricate task effectively. The urgency of proper disassembly cannot be overstated; doing so preserves the functionality of the unit and ensures it remains capable of performing its primary role in solar energy management. Moreover, understanding the internal workings promotes a deeper knowledge of solar technology itself, which can extend beyond just the controller to various photovoltaic applications. By harnessing acquired knowledge, skills can be honed further through practice, experimentation, and a willingness to delve into the intricate engineering behind solar controllers. Equipment longevity can be safeguarded through careful maintenance and educated troubleshooting, laying the groundwork for reliability in solar solutions that aid in harnessing renewable energy sources. The journey of disassembly thus becomes an enlightening pathway, inviting greater engagement with the vital technologies of sustainable energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-street-light-solar-controller/