1. To disassemble the square solar cell box, follow steps meticulously: 1) Ensure safety by disconnecting from power sources, 2) Gather necessary tools, including screwdrivers and pliers, 3) Carefully remove any screws securing the outer casing, 4) Gently detach the wiring harness, ensuring no damage occurs to the components, and 5) Remove the internal components from the enclosure for further inspection or repair. An important aspect is the need to maintain attention to detail to avoid damaging delicate solar cells.

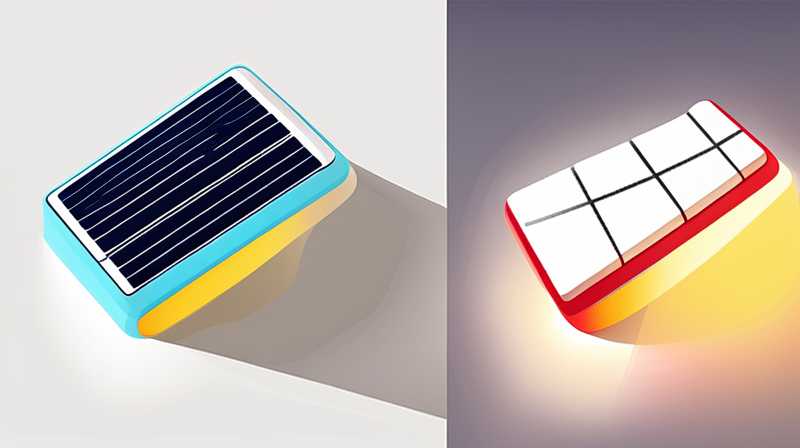

UNDERSTANDING THE SQUARE SOLAR CELL BOX

Disassembling a square solar cell box necessitates a thorough understanding of its components and purposes. Solar boxes house crucial parts, including circuits, inverters, and batteries, which convert solar energy into usable electricity. The reliable operation of these components directly impacts the efficiency of the solar energy system. It is crucial to approach the task with caution and awareness of the importance of each component in the solar energy generation process. Prior knowledge of how solar cell boxes are constructed can aid significantly in the disassembly process.

Before embarking on the disassembly process, one must comprehend the design and layout of the square solar cell box. Typically, these boxes are rectangular enclosures, designed to protect sensitive components from environmental factors like moisture and dirt. They often have a robust exterior made from materials that can withstand harsh outdoor conditions. Inside, the arrangement of various elements must be observed carefully, as improper handling could lead to irreparable damage. Therefore, having a clear layout in mind is essential for reassembly later on.

SAFETY MEASURES PRIOR TO DISASSEMBLY

Safety is paramount when dealing with solar technology. Prior to proceeding with the disassembly process, individuals must adhere to strict safety guidelines to reduce the risk of accidents or injuries. This includes ensuring that all power sources have been correctly disconnected. Power fluctuations can cause electric shock or fire hazards, which can be detrimental. An isolation switch can be beneficial in providing an additional layer of safety and should be switched off before starting any disassembly work.

Furthermore, wearing appropriate personal protective equipment (PPE) is crucial. Items such as safety goggles, gloves, and solutions for falls can prevent injuries during the disassembly process. Another important aspect to keep in mind involves working in a well-ventilated area, as fumes from the materials might be released during disassembly. Keeping the workspace organized enhances both safety and efficiency, minimizing the risk of losing small parts or tools during the procedure.

GATHERING REQUIRED TOOLS AND EQUIPMENT

Having the correct set of tools is essential before disassembling the solar cell box. The process can involve various components that require specific tools such as screwdrivers, pliers, wrenches, and perhaps a multimeter for electrical testing. It is beneficial to gather tools in advance to ensure a seamless workflow. Each tool plays an integral role; for instance, using a flathead screwdriver to remove screws ensures that it does not damage the casing.

Organizing tools effectively can lead to increased productivity during the disassembly. A small toolbox to hold all the required tools can prevent losing items, which can lead to delays. Additionally, consider having a magnetic tray for holding screws or small parts to avoid losing these crucial components during the process. The structured organization of equipment not only facilitates efficiency but also saves valuable time, allowing the user to focus on the actual disassembly rather than searching for misplaced items.

STEP-BY-STEP DISASSEMBLY PROCESS

Embarking on the disassembly process requires careful following of systematic steps. It is important to begin by removing the screws that secure the outer casing of the solar cell box. A screwdriver, ideally one of suitable size for the screws being used, should easily loosen these screws. Ensuring all screws are removed before attempting to take off the casing prevents damage to both the box itself and the interior components. This initial step sets the foundation for successful disassembly, leading to a comprehensive examination of all internal parts.

Once the exterior has been detached, the internal wiring and circuitry become accessible. It is imperative to be cautious during this part of the process, as wires may be sensitive and can lead to short circuits if not handled properly. Gently disconnect each wire from its respective port, using pliers if necessary to avoid putting excessive force on the wires, which could cause fraying or breakage. Labeling each wire may aid in reassembly, as this step mitigates the risks associated with confusing connections.

EXAMINING INTERNAL COMPONENTS

Upon achieving full access to the internal parts of the solar cell box, a thorough inspection can commence. Essential components such as junction boxes, fuses, and inverters should be examined for any signs of wear, corrosion, or damage. Understanding the role of each component can help diagnose issues and guide toward possible repairs or replacements. For example, junction boxes are critical for routing electricity from solar panels to the inverter, and damage here could affect the entire system’s functionality.

Additionally, taking measurements of the voltage and continuity of components may aid in identifying malfunctioning parts. Utilizing a multimeter for these checks is advisable, providing insight into the integrity of circuits and confirming proper connectivity. Thorough documentation of any abnormalities discovered during this inspection is beneficial. This detailed analysis will help inform future repair or replacement decisions, hence enhancing the overall efficiency of the solar system.

PREPARING FOR REASSEMBLY

After completing the disassembly and internal inspection, the subsequent stage involves preparing for reassembly. This process should not be neglected, as it plays a critical role in ensuring functionality and efficiency upon reconnection. Begin by cleaning all components, removing dust or debris accumulated from the exterior and interior of the box. A soft cloth or specific cleaning solutions designed for electronic components can be advantageous, as harsh chemicals might damage sensitive parts.

Next, it is vital to review the condition of seals and gaskets before reassembling the unit, ensuring that moisture cannot seep in post-reassembly. If any components appear frayed or too worn, replacing them is imperative before proceeding to ensure long-term performance. Making a checklist of all parts that need reinstallation helps maintain organization and ensures that no essential parts are missed during the reassembly process.

MAINTAINING SOLAR CELL BOXES POST DISASSEMBLY

Once the reassembly process is complete, the maintenance of the solar cell box becomes paramount for its longevity and efficiency. Regular checks on connections and components are necessary to ensure everything is functioning correctly. Scheduling periodic inspections, ideally twice yearly, to look for signs of wear or degradation can proactively address issues before they escalate into more significant problems. This preventative measure can significantly prolong the life of the solar energy system.

Moreover, documentation of all maintenance activities is fundamental. Maintaining records of inspections or repairs allows for tracking the performance of the solar panel system over time. Should anomalies arise, these records can provide background information essential for understanding any recurring issues and enhancing problem-solving efforts. This disciplined approach cultivates a better understanding of the box’s health and ensures its efficient operation for many years to come.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLY OF A SOLAR CELL BOX?

Disassembling a square solar cell box requires specific tools to ensure each step can be performed accurately without damaging the components involved. Essential tools include a flathead screwdriver, Phillips screwdriver, pliers, and possibly a ratchet set for larger screws. In addition to these, a multimeter is beneficial for testing electrical components to ascertain their functionality post-disassembly. Properly utilizing these tools not only simplifies the disassembly process but also protects the integrity of both the solar cell box and its internal components. Having a systematic toolkit organized can greatly improve efficiency, eliminating delays caused by searching for misplaced items. If any specialized parts or attachments are present in the solar box, having supplementary tools specific to those parts on hand can also prove advantageous. Fostering an environment where all necessary tools are gathered before beginning ensures a smooth workflow and ultimately enables effective and safe disassembly.

HOW CAN I IDENTIFY ISSUES WITH MY SOLAR CELL BOX?

Identifying issues within a solar cell box often involves a detailed process of inspection and testing. After disassembling the box, look for visual signs of wear or damage such as corrosion on terminals, frayed wires, or discolored areas which could indicate overheating. Utilizing a multimeter allows for the checking of voltage and continuity across the various components, offering concrete evidence of functionality. Additionally, understanding the role of each component is crucial; recognizing how they interconnect can make it easier to pinpoint the source of problems. Performing these inspections on a regular basis ensures that potential issues can be addressed proactively before they note significant failures. Creating and maintaining an inspection log can also prove beneficial, allowing for historical tracking of the box’s health and making it easier to identify recurring problems over time.

WHAT COMMON ISSUES CAN OCCUR WITH SOLAR CELL BOXES?

Solar cell boxes, while designed for durability, can experience a range of common issues that may necessitate periodic inspection and maintenance. Some of the most prevalent problems include corrosion of connections, damage from environmental factors, and internal component failures. Corrosion typically arises from exposure to moisture and may interrupt electrical flow, while damage due to extreme weather conditions can lead to physical harm of the unit’s exterior and internal parts. Moreover, components like inverters may suffer from overheating or electrical surges, resulting in breakdowns. Identifying these issues early through regular checks and maintaining rigorous cleaning protocols can negate serious degradation and ensure the efficiency of the solar energy system. Furthermore, being aware of the early signs of issues enables timely intervention and can significantly extend the operational lifespan of the solar cell box.

Effectively disassembling a square solar cell box requires meticulous attention to detail, safety considerations, and proper tool utilization. Starting with a thorough understanding of its internal components enhances the disassembly process, while diligent maintenance ensures longevity. Each component’s role cannot be overstated, as their functioning directly impacts the entire solar energy system’s efficiency. By adhering to organized steps and systematic inspections, individuals can confidently tackle disassembly and contribute to sustaining a well-functioning solar energy system. Maintaining a proactive approach toward regular inspections minimizes risks of failure, thus preserving the investment in renewable energy technology. Ultimately, the knowledge gained through disassembly not only aids in effective repairs but also fosters a deeper appreciation for the workings of solar technology and its contributions to sustainable energy use.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-square-solar-cell-box/