1. UNSCREWING THE VALVE: SOLAR VENTILATION VALVE DISASSEMBLY REQUIRES CAREFUL REMOVAL OF SCREWS, ENSURING NO OTHER COMPONENTS ARE DAMAGED, AND UTILIZING PROPER TOOLS TO PREVENT STRIPPING.

2. INSPECTION OF COMPONENTS: AFTER UNSCREWING, A THOROUGH CHECK OF EACH PART IS ESSENTIAL FOR IDENTIFYING WEAR, TEAR, OR DAMAGES THAT MAY IMPACT FUNCTIONALITY LATER ON.

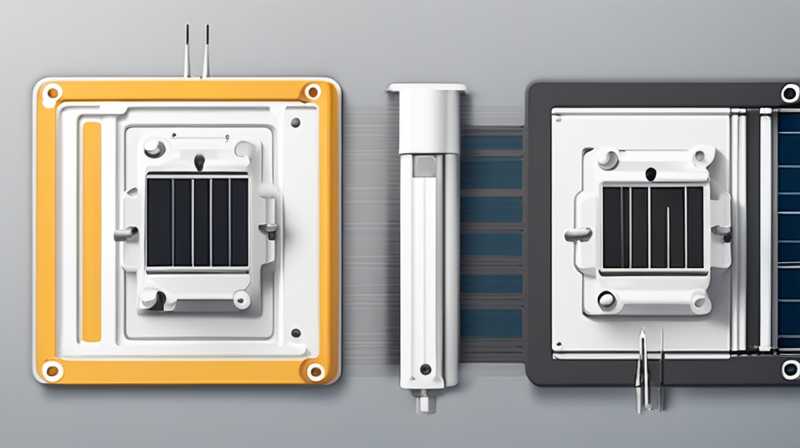

The process of disassembling a solar ventilation valve is intricate and methodical. It necessitates not only an understanding of the mechanisms involved but also the appropriate tools for execution. Engaging with solar technology, particularly components like ventilation valves, involves appreciating their critical role in influencing energy efficiency and indoor air quality. Solar ventilation valves are designed to regulate airflow related to solar heating systems, ensuring optimal performance without compromising energy loss.

When embarking on the task of disassembly, specific tools are indispensable. Among these, a screwdriver set tailored to the variety of screws employed in solar ventilation valves ensures that no part is left damaged or stripped during the process. Having a flat head and Phillips screwdriver on hand will accommodate most common screws. Prying open the ventilation cover often requires careful attention to not induce unwanted damage.

Furthermore, it is prudent to prepare a clean and organized workspace. Busy, cluttered areas can lead to misplacing components or overlooking essential parts during reassembly. Having a tray to hold screws or an identification system for complex components will save time and mitigate confusion later.

1. UNLOCKING THE VALVE ASSEMBLY

The first step in effectively disassembling the solar ventilation valve is to access the initial locking mechanism. Most valves sport several screws or latches, which secure the assembly together, necessitating the use of the appropriate screwdriver to carefully unscrew the top cover. Practicing caution during this procedure is imperative, as over-torquing or mishandling may cause the screw heads to strip.

Once the top of the valve is unscrewed, gently lifting the cover reveals the internal components, typically made of lightweight, durable materials resistant to corrosion. Understanding the layout and function of each part, from the motor to the seals, helps in recognizing which components are critical for successful reassembly. Documenting the configuration with photographs may prove advantageous, enabling a reliable reference during reassembly.

2. REMOVING THE INTERNAL COMPONENTS

With the top cover successfully removed, attention now shifts to detaching the internal components of the valve. This stage identifies the core parts, such as the fan, wiring, and any additional sensors integral to the valve’s operation. Disconnecting wiring harnesses is a delicate task; it is crucial to trace connections carefully to avoid damaging the wiring or misplacing any crucial connectors.

Gently pulling apart the components allows a clearer view of how each part interacts with one another. This is a prime opportunity to inspect for wear or corrosion. Examine the seals and gaskets for any signs of degradation. These components can significantly affect operational efficiency if left unchecked, ultimately leading to compromised ventilation capabilities.

3. CLEANING AND MAINTENANCE CHECK

Before the valve can be reassembled, a meticulous cleaning is advisable. Dust and debris can accumulate in hard-to-reach places within the ventilation system. Utilizing a soft brush or a vacuum attachment helps free these contaminants without causing harm to internal parts. When performing this cleaning, make sure that the motor and other electronic components are not exposed to moisture, which could cause irreparable damage.

Thereafter, it’s prudent to conduct a thorough examination of all essential components, particularly the moving parts. Ensuring that fans rotate freely and that there is no obstruction is vital for optimal performance. Consider applying new lubricant to pivot points, enhancing mobility and reducing friction. Such maintenance is key in extending the lifespan of the ventilation valve, promoting efficiency in energy use.

4. REASSEMBLY OF THE VALVE

Upon completion of the cleaning and inspection process, the subsequent step involves the careful reassembly of the valve. This requires reversing the disassembly steps while paying close attention to the order and orientation of each part. Utilizing photographs taken during disassembly will help ensure that no components are overlooked, and everything is placed back accurately.

During reassembly, retightening screws should be performed with care to avoid over-tightening, which can lead to cracked components or distortion of the casing. Ensuring that gaskets and seals are correctly positioned is crucial; any misalignment can lead to inefficient airflow or leakage, negating the benefits of the solar ventilation valve entirely. After reassembly, test the operation of the valve before sealing it up completely. This final check allows for any last-minute adjustments, ensuring that everything functions correctly.

5. ENHANCING VALVE PERFORMANCE

Enhancing the performance of a solar ventilation valve can significantly influence energy efficiency in a home. Regular maintenance checks, which include inspecting seals and testing electronic components, can preemptively address issues that, if neglected, might lead to higher energy consumption. Additionally, using high-quality replacement parts when necessary can significantly extend the life of the installation.

Another critical consideration is the integration of smart technology with solar ventilation systems. Implementing programmable controls enables homeowners to adjust settings based on their unique ventilation needs, further optimizing energy use. These technological enhancements position solar ventilation systems at the forefront of energy-efficient home solutions.

6. COMMON MISTAKES TO AVOID

Navigating the disassembly of the solar ventilation valve requires an understanding of common pitfalls that may occur. One typical error involves not documenting the disassembly, as attempting to recall the exact order of parts can lead to confusion later. Furthermore, neglecting to examine each component during cleaning can result in failure due to undetected damage.

Another mistake happens when improper tools are used; utilizing incorrect screwdrivers leads to stripping screws or damaging other components. This emphasizes the importance of having the right tools on hand to facilitate a smooth disassembly process. Remaining patient throughout the procedure allows for a thorough approach rather than rushing, which often leads to regrettable errors.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE INDICATORS THAT A SOLAR VENTILATION VALVE NEEDS MAINTENANCE?

Various signs indicate that a solar ventilation valve requires maintenance. Foremost is inefficiency in airflow; if the valve seems incapable of regulating air effectively, it may imply a blockage or malfunctioning internal components. Additionally, unusual noises from the unit could suggest wear and tear on the mechanical parts, necessitating immediate attention. A decrease in the quality of indoor air may also serve as a critical warning sign. If the space becomes hot, humid, or stuffy, the valve could be failing to perform. Regular inspection routines can prevent these situations by addressing small issues before they escalate.

CAN I REPAIR A SOLAR VENTILATION VALVE MYSELF?

Repairing a solar ventilation valve is feasible for individuals with adequate technical knowledge and tools. However, one should keep in mind that certain repairs may require specialized expertise or understanding of the electrical components involved. If the valve has electronic malfunctioning that extends beyond minor repairs, seeking a professional may be a wiser choice. Familiarity with the relevant assembly diagrams and repair manuals can guide non-experts through the repair process. Nevertheless, adequate safety protocols must be adhered to, including disconnecting power sources before starting any repair work.

HOW OFTEN SHOULD I CHECK MY SOLAR VENTILATION VALVE?

The frequency of inspections for a solar ventilation valve typically depends on various factors such as geographical location, usage patterns, and the components’ manufacturer recommendations. However, conducting checks every six months is a good practice to ensure optimal functionality and address any concerns before they become significant issues. During these inspections, focus on cleaning components, checking the integrity of seals, and assessing overall performance. Seasonal checks can also ensure that the valve operates at its best during periods of high use, such as summer months.

7. FINAL THOUGHTS

In essence, dismantling a solar ventilation valve is a detail-oriented operation that requires forethought and preparation. By methodically approaching each phase—right from unscrewing to cleaning and reassembling—one can ensure that the component not only remains intact but continues its role in optimizing energy efficiency in a home or building. Regular maintenance checks and keeping a close watch on the valve’s operation can lead to a longer lifespan and improved performance, ultimately contributing to sustainable energy practices.

These considerations and best practices are crucial for anyone looking to manage their solar ventilation systems effectively. In an era increasingly focused on sustainability, understanding and caring for components like the solar ventilation valve underscores a homeowner’s commitment to energy efficiency and responsible resource management. By being proactive and informed, individuals can enjoy the benefits of a well-functioning system while also contributing to a greener future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-ventilation-valve/