1. Disassembling a solar thermal insulation barrel follows specific steps to ensure safety and efficiency. 2. First, gather essential tools such as a screwdriver, wrench, and safety gloves. 3. Next, locate all the screws and bolts that hold the components together. 4. Carefully remove each part starting from the outer casing inward. 5. Finally, take care to handle materials responsibly for recycling purposes.

Disassembling a solar thermal insulation barrel involves a methodical approach to ensure both safety and functionality. A thorough understanding of the structure and design of the insulation barrel is crucial. This article elaborates on the specific steps, tools, and techniques necessary for the disassembly process while also discussing the importance of safely managing materials post-disassembly.

1. UNDERSTANDING THE STRUCTURE OF A SOLAR THERMAL INSULATION BARREL

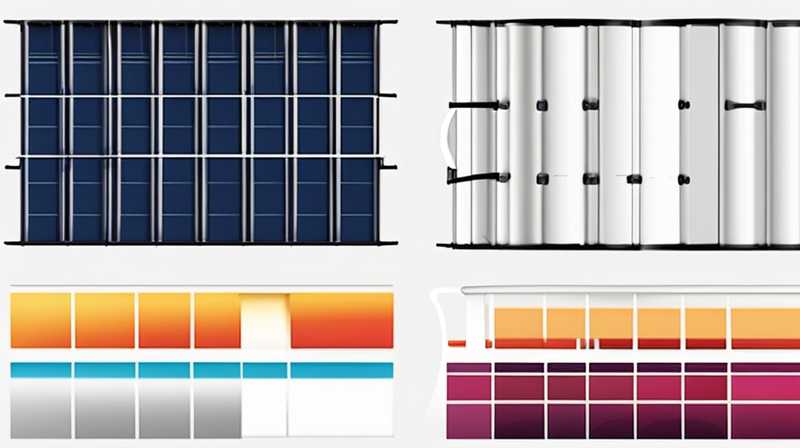

The solar thermal insulation barrel is an essential component of solar water heating systems. Its design promotes efficient heat retention and minimizes heat loss, enabling optimal performance. To effectively dismantle this assembly, one must first comprehend its anatomy, including external casings, insulation materials, and internal tubing.

The outer casing typically consists of weather-resistant materials designed to protect inner components from environmental factors. Inside, layers of insulation, such as foam or fiberglass, serve to minimize thermal conductivity, thereby enhancing the efficiency of the barrel. At the core of the barrel, a series of pipes facilitate the flow of heated fluids. Understanding these layers allows for the safe and systematic removal of each part, preventing potential damage during the disassembly process.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Before initiating the disassembly, it is imperative to gather all required tools and safety equipment. A basic toolkit generally includes screwdrivers, wrenches, pliers, and safety gear such as gloves and goggles. These items will ensure that the process is executed smoothly and safely.

Utilizing the right tools significantly reduces the risk of injury. For instance, safety gloves prevent cuts and abrasions that may occur while handling sharp metal edges. Also, goggles protect the eyes from dust, debris, or any potential harmful substances released during the disassembly. Prior preparation is crucial, as having all the required tools within arm’s reach contributes to a more efficient workflow, minimizing interruptions during the process.

3. LOCATING AND REMOVING SCREWS AND BOLTS

Once the tools have been gathered, the next step involves identifying the screws and bolts that bind the components of the insulation barrel. Typically, these fasteners are strategically placed at various joinery points of the structure. Systematic inspection of the outer casing helps to pinpoint where each screw or bolt is located.

Using the appropriate screwdriver or wrench, carefully begin removing each fastener. Exercise caution during this phase to avoid stripping screws or damaging the threads of the bolts. It can be helpful to keep fasteners organized, such as in a compartmentalized container, to ensure ease of reassembly if necessary. This meticulousness during the disassembly ensures that each component remains intact and reduces the likelihood of misplacing small yet vital parts.

4. REMOVING THE OUTER CASING

With all screws and bolts removed, attention should shift to the outer casing of the insulation barrel. Gently grasping and pulling at the casing should gradually release it from its locked position. If any sections appear stuck due to tight seals or accumulated debris, carefully use a pry tool to assist in the process.

While removing the casing, remain vigilant for any attached wiring, seals, or latches that might still be connected. Detaching these additional components may require minor adjustments or further disassembly of adjacent parts. Ultimately, the goal is to remove the outer casing without causing damage to the underlying insulating layers or internal structure, ensuring a smooth transition to the subsequent steps in the disassembly process.

5. REMOVING THE INSULATION LAYERS

With the outer casing successfully detached, the next object of focus is the insulation layers. These layers are crucial for maintaining the thermal efficiency of the barrel, so care must be taken to avoid tearing or damaging them during removal. Typically, insulation layers can be either rigid boards or flexible materials, each requiring a different methodology for removal.

For rigid insulation, gently loosen any adhesive materials that may be securing them in place. Utilizing a putty knife or flat bar assists in carefully prying the insulation free without causing unnecessary damage. For flexible insulation, one may simply peel away the layers, ensuring they are kept intact for potential future reinstallation or recycling.

6. DISASSEMBLING THE INTERNAL COMPONENTS

Upon removing the insulation, attention should direct itself to the internal components like tubes and fixtures. These parts are generally the most sensitive, requiring utmost care during the removal process. Identifying attachments, connectors, and support structures will help discern the best strategy for disassembly.

Utilizing appropriate tools, detach each component systematically. Always remember to follow the reverse order of assembly to prevent any unwanted damage. For instance, if the inner tubing is connected via clamps or fittings, loosening these connections first before attempting to extract the tubes can prevent unnecessary stress or snapping.

7. MANAGING AND RECYCLING MATERIALS

At this stage, it becomes essential to consider the disposal and recycling of the materials that have been disassembled. Many components of a solar thermal insulation barrel are recyclable, such as metals and certain plastic parts. Understanding local recycling guidelines is vital in managing these materials responsibly.

Separating recyclable parts from non-recyclable materials helps to minimize environmental impact. Local recycling facilities often provide specific instructions on how to handle and process various materials. This responsible approach not only benefits the environment but also promotes sustainability efforts in the community.

8. DOCUMENTING THE DISASSEMBLY PROCESS

While undertaking the dismantling of a solar thermal insulation barrel, meticulous documentation serves as an invaluable asset. Taking photographs or notes throughout the process aids in tracking the order of disassembly and any potential complications encountered. This documented evidence becomes useful in future reassembly or in troubleshooting any issues that may arise post-disassembly.

Moreover, documenting the disassembly process contributes to a greater understanding of the barrel’s functional components and opens avenues for further education and information-sharing. Ultimately, this practice cultivates a deeper appreciation for sustainable energy solutions.

9. ENSURING SAFE STORAGE OF DISASSEMBLED COMPONENTS

As components are disassembled, consideration must also be given to their storage. Placing them in a safe, organized space will protect them from damage or loss. Non-reusable or non-repairable components should be disposed of properly, while reusable ones can be retained for future projects.

Using labeled bins or compartments can significantly reduce confusion, especially if parts need to be stored for extended periods. This organized approach ensures that when the time comes for reassembly or reuse, all essential components are accessible and accounted for.

10. FINAL CHECKS AND WRAP-UP

After disassembling the solar thermal insulation barrel, a final review of the workspace and the disassembled components becomes paramount. This stage allows for identifying any overlooked pieces or tools and ensures that nothing valuable has been accidentally discarded. It is also an opportunity to clean the area, promoting a safe environment for future tasks.

Finally, reflecting on the process can provide insight into best practices for future disassembly tasks, ensuring continuous improvement in techniques and safety. Participating in more complex projects can build confidence while reinforcing sustainable practices within community energy solutions.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE ESSENTIAL FOR DISASSEMBLING A SOLAR THERMAL INSULATION BARREL?

When preparing to dismantle a solar thermal insulation barrel, certain tools are indispensable for the process. A basic toolkit should encompass a variety of screwdrivers, wrenches, and pliers. These items are critical for loosening screws and bolts that hold the structure together. Moreover, incorporating safety gear such as gloves and goggles is paramount to protect oneself from potential injuries, such as cuts or flying debris.

Some additional tools may enhance efficiency during disassembly. For example, a pry bar can be useful in gently separating stuck components, while a putty knife assists in loosening stubborn insulation layers. It is imperative to gather all tools prior to beginning the process to avoid unnecessary interruptions. Taking the time to ensure the proper tools are on hand not only expedites the workflow but also contributes to a safer working environment where accidents can be minimized.

IS IT POSSIBLE TO REASSEMBLE THE BARREL AFTER DISASSEMBLY?

Reassembly of a solar thermal insulation barrel following disassembly is feasible, provided that systematic documentation was maintained throughout the initial disassembly process. Having taken notes or photographs during the initial steps will serve as an invaluable guide during reassembly. Additionally, ensuring that all parts remain intact and are stored securely during the disassembly phase increases the likelihood of a successful reassembly.

Careful attention must be directed at the orientation of components as they are reattached. Understanding the exact order of assembly is crucial for ensuring the barrel’s functionality upon reinstallation. It is advisable to cross-reference with the original installation manuals whenever available. This prudent approach maximizes efficiency while minimizing the possibility of errors that could lead to inefficiencies or damage in the future.

HOW CAN DISASSEMBLING A SOLAR THERMAL INSULATION BARREL SUPPORT SUSTAINABILITY EFFORTS?

Disassembling a solar thermal insulation barrel not only enables maintenance or repair of the unit but also plays a significant role in supporting sustainability efforts. By recycling materials such as metals, plastics, and insulation, one can greatly reduce waste and contribute to the circular economy. The ability to recover and reuse components aligns with principles of sustainability, promoting responsible energy consumption practices.

Moreover, this hands-on engagement fosters awareness about the lifecycle of solar energy technologies. Understanding how these systems work and the materials involved empowers individuals and communities to make informed decisions regarding their energy sources and consumption habits. Engaging in the disassembly process can also inspire further exploration into advancements in renewable energy solutions, promoting a larger shift toward sustainable practices across industries.

FINAL FINDS OF DISASSEMBLY

Effective disassembly of a solar thermal insulation barrel not only enhances understanding of renewable energy technologies but also promotes responsible engagement with materials and resources. Meticulously following all the outlined steps ensures both safety and efficiency throughout the process. Engaging in such hands-on tasks empowers individuals with knowledge and skills, fostering a greater appreciation for sustainable energy solutions. By documenting the disassembly, utilizing the right tools, and managing materials responsibly, practitioners can contribute to environmental sustainability and promote awareness of efficient energy utilization. This process embodies the synergy between education, practicality, and sustainability in modern energy consumption practices, proving that conscientious actions can lead to a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-thermal-insulation-barrel/