To disassemble a solar solenoid valve independently, follow these steps: 1. Gather necessary tools such as a screwdriver, wrench, and safety glasses, 2. Ensure the system is powered off and depressurized, 3. Remove the mounting screws and gently detach the valve from its position, 4. Carefully take apart the solenoid components, paying attention to the spring and plunger, and 5. Inspect and clean the internal parts as needed before reassembly.

1. INTRODUCTION TO SOLENOID VALVES

Understanding the mechanics and functionalities of a solar solenoid valve is pivotal for anyone looking to disassemble and repair it. Solenoid valves serve as critical components in solar heating systems, controlling the flow of fluids based on an electric signal. The precision and reliability of these devices are essential for maintaining proper solar energy utilization. When dealing with maintenance or troubleshooting issues, knowing how to disassemble the valve correctly ensures that repairs can be executed without damaging the internal elements.

The disassembly process can initially appear daunting, yet with the appropriate knowledge and a methodical approach, it can be accomplished successfully. The complex interaction of electrical signals and mechanical movements in solenoid valves necessitates a careful examination of each structure involved. An effective disassembly will allow for thorough cleaning, inspections, and, if necessary, replacements of any faulty components. This understanding forms the foundation for a successful hands-on experience while ensuring safety.

2. TOOLS NEEDED FOR DISASSEMBLY

1. Proper Tools are Essential

Equipping oneself with the right tools is the first step in the disassembly procedure. The most common tools required include various screwdrivers, pliers, a wrench, and possibly a multimeter for electrical testing. Each tool has a specific role in the process. For instance, a flat-head screwdriver is ideally suited for loosening screws that hold the valve in place, while a wrench is necessary for handling any threaded fittings. Having these tools readily available will significantly streamline the work and enhance efficiency.

2. Safety Precautions are Paramount

Before diving into the disassembly procedure, ensuring safety cannot be overlooked. Wearing safety goggles and gloves protects against possible jagged edges or fluid leaks. Moreover, ensuring the power is disconnected and the system depressurized will prevent accidents caused by unintended electric shocks or pressurized fluid release. Taking these precautions mitigates risks significantly, allowing one to focus on the task at hand without undue concern over personal safety.

3. STEP-BY-STEP DISASSEMBLY PROCESS

1. Powering Down and Depressurization

The first action in disassembling a solar solenoid valve involves disconnecting the power supply. This precaution is crucial in preventing any electrical mishaps during the process. After ensuring that all wall switches are turned off, confirm that there are no active connections to the valve. Following this, it is equally vital to depressurize the system fully. Locate the valve’s release mechanism, often near the pump, and allow any remaining fluid pressure to escape safely.

2. Removing the Valve from the System

Once the system is deemed safe, begin the process of removing the valve itself. Depending on your installation, there may be screws or bolts securing the valve in place. Utilize the appropriate screwdriver or wrench to carefully detach these fasteners. Gently pull the valve away from its mounted position, taking care not to disturb any attached pipes. When handling the valve, be cautious of the internal components that may become dislodged during removal.

4. DISASSEMBLING THE SOLENOID COMPONENTS

1. Disconnecting the Electrical Connections

Upon removal, focus shifts to the electrical connections. Locate the wiring harness attached to the solenoid. Take note of the configuration of the wires, as this will be critical for reassembly. Using your multimeter, verify that there is no power flowing through these wires before proceeding. Once confirmed, disconnect the wiring by gently unclipping the connectors. It’s advisable to label each wire if there is any uncertainty about their placement during reinstallation.

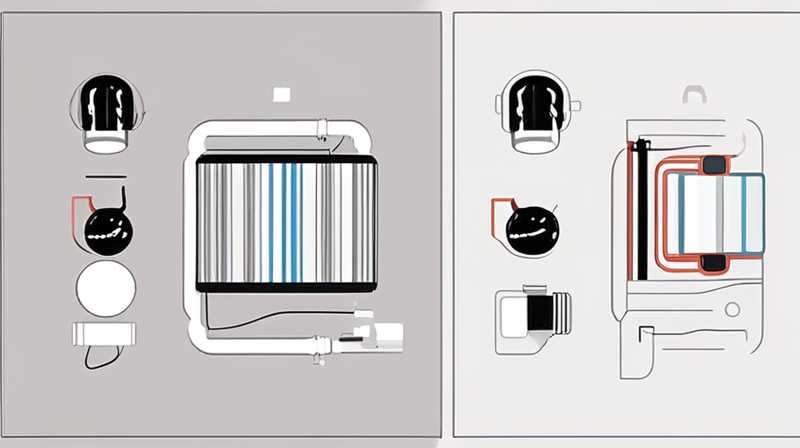

2. Unscrewing and Taking Apart Internal Components

Moving on, locate the screws or fasteners that hold the solenoid together. Using the appropriate screwdriver, carefully remove these, ensuring each component is kept in a secure location for easy identification later. Begin gently taking apart the solenoid casing, noting that springs and plungers may be under tension. Handle these components with care, as they can easily be lost or damaged if not properly managed. Ensuring a systematic approach allows for a smoother reassembly process later.

5. INSPECTING AND CLEANING THE VALVE

1. Assessing for Damage and Wear

After disassembling the valve and solenoid components, it’s important to inspect each part for signs of wear or damage. Pay special attention to the seating surfaces where seals engage, as any imperfections here can lead to leaks. Utilize a magnifying glass if necessary to detect small cracks or deformities in the materials. Additionally, check for the presence of dirt, corrosion, or debris that may have accumulated within the solenoid or valve body. Understanding the condition of these elements is essential for determining if replacement parts are needed.

2. The Importance of Cleaning Internal Areas

Thoroughly cleaning the internal and external surfaces of the valve not only aids in ensuring effective operation but can also prolong the lifespan of the components. Use an appropriate solvent to remove grease, debris, or any mineral build-up that may impair functionality. Soft brushes can be useful for reaching confined spaces without risking damage. For rubber seals or gaskets, it may be wise to replace them entirely instead of attempting to clean them, as they can experience wear over time and lead to further complications.

6. REASSEMBLING THE SOLENOID VALVE

1. Following the Reverse Procedure

With all components clean and inspected, the next stage involves reassembling the valve. Following the reverse order of disassembly is critical to ensure accuracy. Start by placing the plunger and spring back into their proper positions within the solenoid. Secure the solenoid casing with screws, ensuring each is tightened adequately but not overtightened to prevent stripping the threads.

2. Reattaching Electrical Connections with Care

After the internal components are secured, reattach the electrical connectors, making sure to replicate the original layout accurately. This attention to detail will prevent malfunctions when power is restored. Furthermore, reconnect the solenoid valve back to its mounting location and secure it with the appropriate screws. It is vital to maintain a level of care during this process to ensure that each connection is stable and leak-proof upon system reactivation.

7. TESTING FUNCTIONALITY AFTER REASSEMBLY

1. Restoring Power and Monitoring

With the entire assembly process complete, the next essential step is to restore power to the system. Before fully engaging the complete system, it’s advisable to fill the system slowly with fluid to check for any leaks around the valve or solenoid connections. Observe the behavior of the valve as the system pressurizes, ensuring it opens and closes correctly according to the control signals. This step is crucial for avoiding future complications and ensuring that the solenoid operates as intended.

2. Regular Maintenance to Ensure Longevity

Beyond the initial reassembly and testing, it’s important to form a routine maintenance schedule. Regular inspections and cleanings can help catch potential issues before they escalate. This proactive approach can significantly extend the lifespan of the solar solenoid valve and enhance the efficiency of the entire solar heating system. Understanding the working conditions that these parts operate under ensures that owners will benefit from optimal performance over extended periods.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLENOID VALVE AND HOW DOES IT WORK?

A solenoid valve acts as a device that regulates the flow of fluids or gases within a system using electromagnetic forces. The operation begins when an electrical current passes through the solenoid coil, generating a magnetic field that moves the plunger upward. This action opens or closes the valve’s orifice, allowing fluid to either flow or be blocked. Solenoid valves are essential in automated systems, incorporating them in irrigation, heating, refrigeration, and various industrial applications. Their reliable operation aids in maintaining the efficiency and safety of fluid handling systems.

HOW DO I KNOW IF MY SOLENOID VALVE IS FAULTY?

The signs of a malfunctioning solenoid valve may manifest in various ways. Common symptoms include leaks around the valve, erratic operation where the valve may not open or close properly, or complete failure to respond to electric signals. Additionally, unusual noises or vibrations when the system is engaged can indicate internal issues. Testing with a multimeter can determine whether the solenoid is receiving power and functioning as intended. If these symptoms are present, it may be beneficial to proceed with disassembly and further inspection, as outlined in the disassembly process.

IS IT SAFE TO DISASSEMBLE A SOLENOID VALVE MYSELF?

Disassembling a solenoid valve can be safe if proceeding with the necessary precautions and knowledge. Prior to starting, ensuring safety by disconnecting power and depressurizing the system is critical. Following a systematic approach and having the right tools also significantly reduces the risk of accidents occurring. Those unfamiliar with mechanical or electrical systems may consider consulting a professional for assistance to mitigate the chances of damaging the equipment or injuring oneself. Overall, the key to a safe disassembly lies in preparation and careful execution of each step as described.

It is imperative to approach the task of disassembling and reassembling a solar solenoid valve with both caution and knowledge. Engaging with these mechanical and electrical components bears the potential for well-executed repairs that can sustain the operational integrity of an entire solar heating system. By methodically following each step, from gathering appropriate tools to conducting thorough inspections, the reliability of the valve can be restored effectively. Regular maintenance following repairs also plays a vital role in ensuring ongoing efficiency—a proactive measure to avoid sudden failures. Thus, investing time and effort in understanding these components will ultimately lead to a better experience with solar energy usage, contributing to broader sustainability goals. Whether one is a seasoned technician or a novice at home repairs, mastering solenoid valve disassembly offers invaluable insights while fostering a more hands-on approach to maintaining renewable energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-solenoid-valve-yourself/