To effectively disassemble a solar solenoid valve coil, following proper steps is crucial. 1. Prepare the workspace: Ensure a clean, organized area with adequate lighting and necessary tools. 2. Gather tools: Collect tools such as wrenches, screwdrivers, and pliers to facilitate the process. 3. Disconnect power: Safety is paramount; disconnect all power sources before proceeding. 4. Remove the coil: Carefully detach the coil from the valve assembly. Focusing on the disconnection process is vital; ensure that all electrical components are carefully handled to prevent damage or accidents. This careful approach will not only ensure safety but also maintain the integrity of the remaining components.

1. UNDERSTANDING SOLENOID VALVES

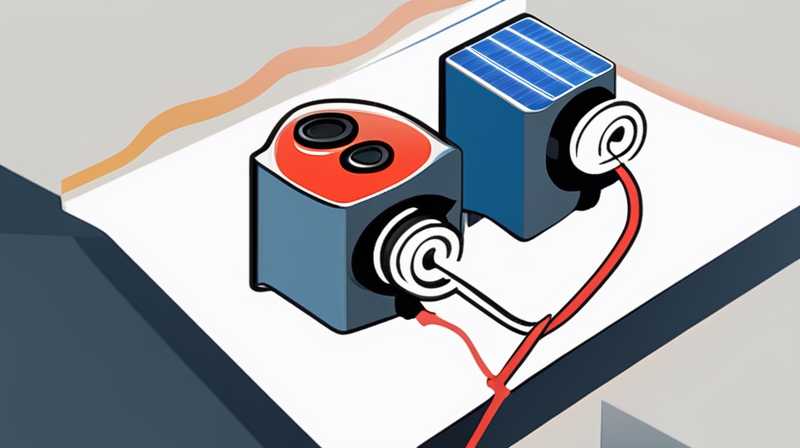

A solar solenoid valve plays a pivotal role in regulating fluid flow within various applications. These components are integral to automated systems that require precise control. In essence, solenoid valves utilize an electromagnetic coil to actuate a mechanism that either allows or blocks fluid passage. This functionality is particularly crucial in solar systems where water flow management is essential for efficiency.

The importance of fully grasping the structure of a solenoid valve cannot be overstated. Understanding the internal mechanisms lets technicians anticipate the potential challenges involved in disassembly. A solar solenoid valve coil forms the heart of the device, triggering the opening and closing motions. By studying the operation, one gains insights into various types of solenoid valves and their specific features, enabling more informed decision-making during repairs or replacements.

2. TOOLS REQUIRED FOR DISASSEMBLY

Having the correct tools at one’s disposal is essential for a successful disassembly procedure. 1. Wrenches: Used for loosening bolts and nuts that secure the coil to the valve body. 2. Screwdrivers: Essential for removing screws in the assembly. 3. Pliers: Helpful in gripping and pulling components apart. 4. Electrical tape: Useful for marking and insulating wires as needed. Each tool plays a significant role, and employing them correctly can minimize the risk of damaging sensitive components.

Additionally, the use of specialized tools can enhance the overall efficiency of the process. For instance, if the solenoid valve includes intricate parts, a magnetic tool can help retrieve small screws that may fall into hard-to-reach places. Lastly, organizing tools neatly ensures a less chaotic environment, which aids focus, decreases misplacing items, and allows for a smoother workflow throughout the disassembly.

3. SAFETY PRECAUTIONS

When dealing with electrical components, safety measures are critical. The first step is ensuring that all power sources are disconnected. This includes unplugging the unit and turning off any associated circuit breakers. Moreover, safety goggles and gloves should be worn during the process. Such precautions serve to protect against possible hazards like electric shock or injuries from sharp parts.

Another crucial aspect is being aware of the specific type of coil being disassembled. Different models may have unique features or requirements. By consulting the manufacturer’s manual, one can acquire necessary safety guidelines tailored to the specific solenoid valve coil. Understanding cautionary practices is vital in preventing not only personal injuries but also damage to the components, which could lead to costly repairs or replacements.

4. DISASSEMBLING THE SOLENOID VALVE COIL

The actual process of taking apart the coil involves careful attention to each step. 1. Begin by locating the screws or bolts that hold the coil in place. 2. Using the appropriate tools, gently unscrew these fasteners to avoid stripping any threads. 3. After loosening, lift the coil away while being cautious of any attached wiring. It is vital to note the configuration of all components to ensure accurate reassembly later.

Once the coil is removed, it’s essential to disassemble it further if needed. Look for any remaining screws that may hold together different parts of the coil assembly. Gently pry apart the sections, ensuring not to damage any fragile components. If resistance is encountered, double-check for overlooked screws or fasteners, which may contribute to the difficulty in separation. By remaining patient and methodical, the disassembly process will produce fewer complications and maintain the integrity of all parts.

5. INSPECTING COMPONENTS AFTER DISASSEMBLY

Upon disassembly, a thorough inspection of the individual parts is paramount. Begin by checking the coil itself for signs of wear and tear, such as cracks or corrosion.=> Additionally, the insulation around copper wires should be intact; any fraying could lead to malfunctions. Understanding the condition of each component informs future decisions about repairs or replacements.

It is also beneficial to clean the parts during the inspection phase. Utilizing a soft cloth can help remove dirt, debris, or residue that might hinder performance. If any component appears compromised, sourcing a replacement part promptly can prevent extended downtime. Lastly, maintaining an inventory log of the inspected components can streamline future repairs and enhance overall efficiency.

6. REASSEMBLY OF THE SOLENOID VALVE COIL

Once complete inspection and cleaning are conducted, the reassembly of the solenoid valve coil can commence. 1. Begin by aligning the coil sections according to the initial configuration. 2. Use the same screws or bolts that were removed during disassembly to secure the parts in place. Proper alignment is crucial for ensuring operational efficacy post-reassembly.

In concluding this process, one should perform a final check of all connections. Ensure that the wires are properly insulated and securely fastened to their respective terminals. Before reconnecting the power source, a visual inspection can verify that everything is correctly in place. Reassembling correctly is fundamental to preventing future issues and enhances the longevity of the solenoid valve.

7. COMMON ERRORS DURING DISASSEMBLY

Understanding frequent mistakes can significantly improve one’s approach to the task. 1. Over-tightening screws: This can result in stripping the threads or damaging the valve. 2. Failing to document configurations: Noting the arrangement of components during disassembly can lead to confusion when reassembling. Recognizing these potential pitfalls empowers technicians to operate more effectively.

Furthermore, neglecting careful inspections of the components can also result in overlooking critical wear issues. 1. Sound judgment in discerning when to replace a part versus repairing is vital for efficiency. 2. Upscaling knowledge through experience will lead to improved skill sets that enhance overall professionalism. Avoiding these common errors leads to more streamlined, efficient processes and heightened performance in future endeavors.

FAQs

HOW DO I KNOW IF MY SOLENOID VALVE IS FAULTY?

Identifying a malfunctioning solenoid valve may seem daunting; however, a few signs typically indicate issues. The first indication often comes from unusual operational sounds, such as clicking or buzzing, which may suggest electrical problems or an internal blockage. Moreover, if the valve fails to respond when powered, it’s likely the coil is burnt out, requiring inspection or replacement.

Other symptoms include leaks around the valve assembly, which might stem from wear in internal rubber seals or gaskets. Regularly scheduled maintenance and observation of these signs can prevent more significant issues later on. If the valve operates sporadically, it is crucial to conduct a detailed inspection. While some problems can be fixed through cleaning or tightening, others may necessitate a complete replacement for optimal function.

WHAT MAINTENANCE SHOULD I PERFORM ON A SOLENOID VALVE?

Routine maintenance plays a significant role in enhancing the longevity and efficiency of solenoid valves. Regular inspections should include examining electrical connections for signs of corrosion or wear, as this can lead to performance issues. Additionally, clean the valve periodically to remove debris that could obstruct flow. Employing quality lubricants can also aid in maintaining smooth operations.

Moreover, it is crucial to test the solenoid’s operation regularly by applying power and observing its response. This proactive approach allows for early detection of potential issues before they escalate. Keeping detailed logs of maintenance activities helps in identifying patterns and scheduling repairs as necessary. By conducting these checks, one can significantly reduce the likelihood of malfunctions.

CAN I REPAIR A DAMAGED SOLENOID VALVE COIL MYSELF?

Repairing a damaged solenoid valve coil is often feasible, provided one possesses a basic understanding of the repair process and necessary tools. Common issues include frayed wires or blown fuses, both of which can generally be repaired with minimal expertise. Replace damaged wires by cutting back the insulation and splicing in new wire carefully and securely. Always consult manufacturer specifications for guidelines on wire types and ratings.

However, if the damage is extensive, replacing the entire coil may be more practical. Attempting to repair complicated or severely damaged parts should be approached cautiously as improper handling may lead to increased malfunctions. Prioritize safety and ensure that power sources are disconnected during any repairs. Ultimately, weighing the cost and time involved in repair versus replacement will lead to the best decision for maintenance.

Ensuring the longevity of a solar solenoid valve coil requires careful handling and attention to detail throughout both disassembly and reassembly processes. The attention to safety and the methodical approach can significantly reduce risks associated with these components. Gaining mastery over these practices enables technicians to enhance their skills, ultimately contributing to more reliable and efficient operation of systems reliant on these critical devices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-solenoid-valve-coil/