To effectively disassemble a solar solenoid valve involves several intricate steps. 1. Gather necessary tools, 2. Ensure safety protocols are followed, 3. Carefully remove the electrical connections, 4. Detach the valve body from its housing. Each of these points requires specific attention to ensure that the disassembly process is completed effectively without damage to the components.

1. UNDERSTANDING THE COMPONENTS

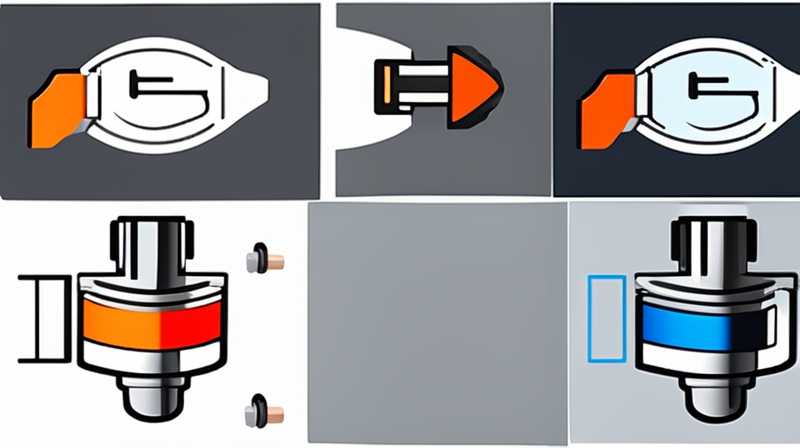

Disassembly of a solar solenoid valve necessitates a firm grasp of its internal and external components. The solenoid valve functions primarily as an electromechanical device, controlling fluid flow in solar heating systems. It comprises a solenoid coil, a plunger, and valve body, each playing a critical role in its operation. The solenoid coil generates a magnetic field upon electrification, subsequently pulling the plunger upward against spring tension. This mechanism either opens or closes the valve, allowing fluid passage or halting flow.

Understanding this mechanism is vital before attempting disassembly. Inappropriate handling could lead to irreparable damage, ultimately resulting in system inefficiencies or malfunctions. Familiarization with these parts enables a technician to identify particular points of fault and execute repairs effectively.

2. PREPARATION FOR DISASSEMBLY

Before embarking on disassembly, meticulous preparation is paramount. Firstly, ensure that you have all requisite tools. Common tools include a screwdriver set, wrench, pliers, and possibly a multimeter to check electrical connections. Gathering these items before starting the process streamlines the procedure and reduces the likelihood of interruptions caused by searching for tools mid-task.

Equally important is adhering to safety precautions. This involves disconnecting power sources and ensuring that the unit is not under pressure. If the valve has been recently in operation, waiting for a cooling period is wise to avoid burns or injuries. Furthermore, wearing gloves and safety goggles can help protect hands and eyes from debris during disassembly.

3. DISCONNECTING ELECTRICAL COMPONENTS

Prior to taking apart the valve, it’s crucial to address the electrical components carefully. Commence by unplugging the solenoid coil. This is typically done by releasing clips or unscrewing terminal connections. Careful attention is required during this step as the prongs can be delicate. Short circuits or grounding issues can occur if the disassembly is not conducted accurately.

After disconnecting the power supply, inspect the electrical connections for signs of wear or corrosion. This can provide insights into the valve’s prior performance. If any deterioration is evident, make a note of it for replacement with new parts once the disassembly and cleaning processes are complete. Thorough recording of the original setup can aid in reassembly, saving time and ensuring correct operation.

4. REMOVING THE VALVE BODY

With electrical components safely disconnected, turn your attention to the physical disassembly of the valve body. This often involves unscrewing several fasteners or bolts that secure the main valve assembly to its housing. Use the appropriate wrench or screwdriver based on the type of fasteners present. If rust or other obstructions are evident, consider applying a penetrating oil to ease removal.

Once unfastened, gently wiggle the valve body free. Be cautious not to apply excessive force which might damage internal seals or small components. A steady and patient approach can prevent unnecessary repairs later. While detaching, have a clean workspace prepared for placing each part systematically to avoid losing small items during the process.

5. INSPECTING INTERNAL COMPONENTS

After successfully separating the valve body from its assembly, turn your focus to the internal components. Inspection is a vital step in the disassembly process. Look for signs of wear on seals, springs, or the plunger itself. Any discoloration, deformities, or breakdown of materials could indicate the need for replacement, thus affecting performance once reassembled.

Special attention should be paid to the solenoid coil area. This is where failures often arise due to electrical issues or insufficient power supply. Check the insulation on the wires leading to the coil; signs of fraying or breaking should be resolved before the valve is re-installed. Additionally, understanding the failure points can support future maintenance and enhance the longevity of the system under continued use.

6. CLEANING AND MAINTENANCE

With all components laid out and inspected, the next priority is cleanliness. Debris, mineral buildup, and contaminants can significantly impede the function of solenoid valves. Using appropriate cleaning agents, thoroughly clean all parts, with special attention to the valve seat and plunger area, as residue here can obstruct smooth operation.

Debris penetrating the solenoid body can result in operational inefficiencies; therefore, ensure all surfaces are free of oils, dirt, and corrosion. Incorporating a soft brush or vacuum at this stage may aid in eliminating stubborn buildup. A grasp of the cleaning techniques enhances the durability of the part during the operational cycle and contributes to reliable renewable energy systems.

7. REASSEMBLY PREPARATIONS

Once cleaning is diligently executed, prepare for the process of reassembly. Assess and gather all components to confirm all items are ready to be put back together. A systematic approach promotes a seamless reintegration of parts into their proper positions. Matching old components with new replacements ensures that discrepancies do not go unnoticed.

Installation of new components should be methodical. This can help in solidifying a proper snug fit without causing damage or misalignment. Replacement materials should be selected based on compatibility to ensure longevity within the solar heating ecosystem. Reviewing manufacturer specifications during this stage can safeguard against fitting errors.

8. REASSEMBLY OF THE VALVE

In reassembling the valve, starting from the internal components to the outer shell is advisable. Begin by placing the plunger back into the valve body, ensuring it moves freely without obstruction. Reattach seals where necessary, and ensure that the coil and electrical connections remain accessible for future maintenance.

Once the internal elements are securely positioned, return the outer valve casing to its rightful place. Fasteners should be tightened adequately without overtightening, as this may cause deformation or damage to the plastic or rubber components. A reliable torque specification might enhance the durability of the entire assembly, offering confidence once reinstated in the solar system.

9. RECONNECTING ELECTRICAL COMPONENTS

Following successful reassembly, reconnect electrical components to their respective terminals. Ensure that connections are secure and observe polarity to prevent improper functionality. Double-checking the wiring can avert potential mishaps caused by incorrect installation.

Consider using a multimeter to test continuity and voltage levels before fully reintegrating the valve into the operational system. This testing serves to validate that the electrical components are functioning properly, correlating correctly to their required operational capabilities. Ensuring these connections are sound can aid in maintaining optimum performance levels during operation down the line.

10. FINAL CHECKS AND SAFETY MEASURES

With the valve now reassembled and connections tested, the last step is performing a thorough check prior to issuing the unit back into operational status. Inspect all fasteners, seals, and connections once more to verify that everything is in place and secure. Filling the system with fluid should be executed gradually, monitoring for leaks.

Safety protocols remain vital during this stage. Gradually apply power to the device and monitor the operational effect of the solenoid valve as it adjusts to openings and closings. Watching for any irregular noises or responses can aid in identifying potential issues immediately. Adjustments may need to be made based on this initial testing.

11. MAINTENANCE AND FUTURE CARE

Regular upkeep of solar solenoid valves is essential for extended durability and performance efficiency. Establishing a schedule for routine checks and cleanings will prevent many common issues associated with buildup. Inspections should include examining electrical connections, seals, and overall mechanical integrity.

Documenting the condition of the valve post-testing serves to track any changes over time. This can provide crucial insights into performance trends, assisting in preemptive repairs or replacements. A consistent monitoring system will ultimately contribute to a well-functioning solar energy system, supporting sustainability goals.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF TOOLS ARE NEEDED FOR DISASSEMBLY?

To disassemble a solar solenoid valve, specific tools are crucial for efficiency and effectiveness. Commonly required tools include a screwdriver set, adjustable wrench, pliers, and potentially a multimeter to ascertain electrical connection integrity. Additionally, a soft brush and cleaning solutions may assist in eliminating debris found inside the valve. It is also suggested to have a container or organized workspace to avoid misplacing small components during assembly.

When preparing to disassemble, it is imperative to prioritize safety by ensuring the power supply is disconnected and the system has cooled down. Proper tool selection will not only streamline the disassembly procedure but also aid in the proper upkeep of the valve components. Finally, ensuring that tools are in good working condition will make the process smoother, reducing the risks of damaging the valve assembly.

ARE THERE ANY SAFETY PRECAUTIONS TO FOLLOW?

Indeed, adhering to safety measures during the disassembly of a solar solenoid valve is paramount. Initially, ensure that the power supply is completely disconnected to avoid the risk of electric shock. Next, examine the valve for pressurization or heat; if the valve was recently operational, allow time for cooling and depressurization before commencing disassembly.

Wearing safety gloves and goggles also contributes to personal safety, shielding against unexpected debris dislodging during the process. Should spills occur, addressing them promptly with suitable absorbents prevents health or environmental hazards. Working in a well-ventilated space can further enhance safety, especially if cleaning solvents are being utilized. In essence, a cautious approach will significantly mitigate potential injury during this technical undertaking.

HOW CAN I TELL IF THE VALVE NEEDS REPLACEMENT?

Determining whether a solar solenoid valve requires replacement can be challenging but necessary for maintaining optimal performance. Signs indicating replacement may include persistent leaks, slow response times, or visible physical damage to components such as cracks or corrosion. If the valve continuously fails to open or close, this may reflect electrical or mechanical failure, warranting further examination.

Additionally, unusually high energy consumption or performance inconsistencies within the solar energy system can signal malfunctioning components. Electrodes and coils that show signs of overheating or discoloration suggest imminent failure. If attempts at repairs yield no results or if multiple components show signs of wear, replacement may be the most feasible and cost-effective solution. Therefore, close monitoring of the valve’s performance and condition remains crucial in determining its operational viability.

FINAL THOUGHTS ON SOLAR SOLENOID VALVES

The disassembly of a solar solenoid valve, while intricate, can be successfully executed through careful planning and execution. This process includes comprehensively understanding the valve’s structure, preparing the workspace, and ensuring safety throughout each phase. Accurate disassembly and subsequent reassembly pave the way for extended life and functionality of the valve, solidifying its role within a solar energy system.

Precautions, proper tool selection, and systematic inspections all underscore the complexity of the task involved. Additionally, commitment to regular maintenance checks enhances performance sustainability while forestalling premature failures. The insights gained during disassembly also promote a better understanding of overall system operations, contributing to informed decision-making on repairs and upgrades.

Ultimately, grasping the detailed methodology behind the disassembly of solar solenoid valves empowers technicians to embrace challenges with confidence and efficiency. By cultivating a high level of technical knowledge and practical skills, better outcomes in maintenance and longevity of renewable energy components can be achieved, enhancing the resiliency and reliability of solar energy systems. Proper care ensures that these valuable components operate seamlessly, supporting eco-friendly initiatives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-solenoid-valve/