1. The process of disassembling a solar round valve involves several essential steps, including preparation, removing the valve from the plumbing system, disassembling the valve components, and maintaining safety precautions. 2. Understanding the specific type of solar round valve is crucial for successful disassembly. 3. Utilizing appropriate tools and following manufacturer guidelines will ensure seamless disassembly and reassembly. 4. Regular maintenance of the solar round valve ensures longevity and optimal performance.

1. UNDERSTANDING SOLAR ROUND VALVES

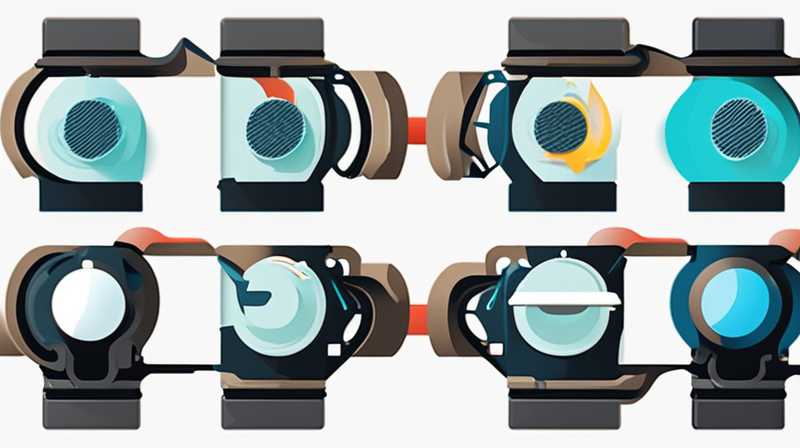

The solar round valve plays a pivotal role in solar heating systems by controlling the flow of heat transfer fluid. Efficient management of this flow is necessary for the system’s performance and longevity. Familiarity with the components and functionality of the solar round valve is paramount for anyone looking to disassemble it. Often, these valves are tailored to specific solar systems, so comprehending the particular model being dealt with will guide the disassembly process.

In essence, the solar round valve consists of multiple components that include the valve body, actuator, seals, and often a manual override. Each of these parts has its specific function, which not only contributes to the operation of the valve but also impacts the overall performance of the solar heating system. It’s worth noting that improper handling during disassembly can damage these components, leading to potential inefficiencies or leakage when reassembled. Therefore, having a structured plan in place is vital for anyone embarking on this task.

2. PREPARATION FOR DISASSEMBLY

Preparation stands as a fundamental prerequisite to ensure a smooth disassembly process. Initiating this procedure involves gathering the necessary tools and materials, including screwdrivers, wrenches, pliers, and safety gear. Each tool serves a specific purpose, and neglecting any of these could result in complications during disassembly. Furthermore, ensuring that the working area is clean and organized can significantly enhance efficiency and minimize the risk of misplacing components.

Equally important is the evaluation of the solar heating system to identify any operational issues prior to disassembling the valve. This entails checking the fluid levels, inspecting for leaks, and understanding how the valve integrates within the broader plumbing system. This assessment can provide insights into potential challenges that may arise during disassembly, thus enabling a preemptive approach to address them. Taking pictures or making notes can also be beneficial, providing visual references for reassembly later.

3. REMOVING THE VALVE FROM THE PLUMBING SYSTEM

The extraction of the solar round valve from the plumbing system requires delicate attention to detail and adherence to safety protocols. Initially, one should ensure that the entire solar system is turned off to prevent any accidents during the process. Closing the isolation valves on either side of the solar round valve will prevent fluid from spilling out during removal, mitigating the risk of exposure to hot or pressurized fluids.

After ensuring the flow is stopped, the next step is to disconnect any electrical connections associated with automated valves. This could include disconnecting sensors or actuators that are electrically driven. Utilizing the appropriate tools, one can then loosen the valve’s coupling nuts or bolts to detach it from the piping. It is critical to utilize caution while disassembling to avoid stripping threads or damaging adjacent components. Ensuring that appropriate alignment and grip techniques are used preserves the integrity of the valve connections.

4. DISASSEMBLING THE VALVE COMPONENTS

The actual disassembly of the solar round valve begins once it has been successfully removed from the plumbing system. With careful attention, one can start by taking off any external nuts or screws. Each component should be cataloged meticulously to facilitate accurate reassembly. If necessary, consulting the manufacturer’s service manual or technical guides can provide crucial insights into the method of disassembly without causing damage.

Moving deeper into the valve structure, certain internal parts might require gentle prying or turning to dismantle. Care must be exercised so as not to damage any seals or gaskets that could lead to leaks upon reassembly. Understanding the orientation and secure arrangements can also aid in reconfiguring the parts in the same way eventually. If parts appear worn or show signs of degradation, replacements should be obtained to ensure the solar system continues running efficiently after reassembly.

5. SAFETY CONSIDERATIONS

Prioritizing safety during any disassembly process cannot be overstated. Proper personal protective equipment should be worn at all times, including safety goggles, gloves, and long sleeves. Adequate ventilation in the workspace can minimize any inhalation risks if old substances are being handled. Additionally, having a first-aid kit readily accessible can prove invaluable in the case of any mishaps.

Awareness of the possibility of residual pressure or hot fluids remaining in the system is crucial. Allowing ample cooling time for the system before disassembly can prevent serious burns or injuries. Furthermore, one should avoid working alone in case assistance is needed; ensuring someone else is present can provide support and improve safety throughout the process.

6. MAINTENANCE AFTER DISASSEMBLY

Post disassembly, maintenance is a critical aspect that ensures the solar round valve continues to operate smoothly. Inspecting each component thoroughly for wear and potential failure points can proactively address any issues before they escalate. Replacing gaskets, seals, or inner components that appear compromised is a fundamental part of maintenance, preventing leakage or inefficient operation in the future.

After reassembling, conducting a thorough test to evaluate the valve function within the system context is necessary. This entails observing any unusual sounds or leaks during operation, ensuring that all connections are tight and secure. Performing routine checks at regular intervals can prolong the life of these valves and contribute significantly to the effectiveness of the solar heating solutions.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE REQUIRED FOR DISASSEMBLING A SOLAR ROUND VALVE?

Disassembling a solar round valve effectively necessitates specific tools, tailored to facilitate careful handling of the components involved. A complete toolkit often includes screwdrivers (both flathead and Phillips), various sizes of wrenches or socket sets, pliers, and often a utility knife for cutting any adhesive or seals. Moreover, a torque wrench is advantageous for ensuring that screws and bolts are tightened to the correct specifications during reassembly.

Safety equipment, including gloves, goggles, and long-sleeved clothing, must not be overlooked. During disassembly, it is essential to protect oneself from potential hazards associated with the fluid contained within the solar system. Any existing electric components might also require specialized tools, catering to electrical connections. Having an organized workspace where these tools are laid out systematically can improve convenience and efficiency during the entire operation.

HOW DO I IDENTIFY THE TYPE OF SOLAR ROUND VALVE I HAVE?

Determining the specific type of solar round valve in use is crucial for successful disassembly and maintenance. Typically, identification is facilitated by examining the manufacturer’s label or model number, often found on the valve body or actuator. Different models may feature unique designs, such as differing sizes or connection types. Many manufacturers also provide online resources or manuals where specifications pertaining to particular models can be reviewed.

Additionally, understanding the valve’s functionality can aid in identifying its type. Recognizing whether it’s a check valve, ball valve, or another configuration will direct how the disassembly should proceed. Each style may require diverse handling or technique. Engaging with local suppliers or professionals who specialize in solar heating systems can also enhance knowledge regarding specific valve types and their operational characteristics.

WHAT MAINTENANCE SHOULD BE PERFORMED AFTER REASSEMBLY?

Upon successful reassembly of a solar round valve, implementing ongoing maintenance is crucial for the longevity and efficiency of the valve as well as the entire solar heating system. Initially, a leak test should be conducted post-assembly while the system is operational, observing both the valve and the connected components for any potential leaks. Should any drips or moisture appear, addressing these swiftly will prevent larger issues in the future.

Implementing a routine inspection schedule is also advisable, checking for rust, corrosion on metal parts, or wear on the seals and gaskets. Cleaning any debris or mineral build-up can greatly enhance performance, especially in areas with hard water. Keeping an eye on the heating fluid’s condition ensures that the solar system runs optimally, maintaining both efficiency and effectiveness in heat transfer.

The procedure of disassembling a solar round valve requires meticulous attention to detail and adherence to safety protocols throughout the entire process. Preparation is the bedrock upon which a successful disassembly is built. Ensuring that the system is offline, gathering the right tools, and assessing the valve’s condition before proceeding establishes a secure foundation for the task at hand. Mastering the removal of the valve from the plumbing system with precision ensures that each step is handled with care, mitigating the possibility of damage to surrounding components.

Diving into the valve’s internal structure, a careful and methodical approach will facilitate effective disassembly without compromising the integrity of the parts involved. Addressing safety considerations throughout the operation, such as utilizing personal protective equipment and being aware of potential hazards, will safeguard against accidents and injuries. Once the disassembly is complete, maintaining the components diligently is equally important to prolong the lifespan of the valve. A commitment to regular checks and prompt replacements of any deteriorating parts will ensure the solar heating system remains efficient and effective. Through comprehensive understanding and careful action, the delicate process of disassembling solar round valves can be accomplished successfully.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-round-valve/