1. Disassembling a solar pipeline joint necessitates careful attention to detail, a clear understanding of the components involved, and adherence to safety protocols. 1. Gather necessary tools, 2. Wear safety gear, 3. Identify the type of joint, 4. Loosen connections following the manufacturer’s guidelines. It’s crucial to pay particular attention to the disassembly process, especially regarding the type of joint utilized in the solar pipeline system. Depending on the specific system design, solar pipeline joints can vary significantly in their construction and materials. A systematic approach to disassembling these joints ensures not only safety but also the integrity of the remaining pipeline structure, facilitating a smooth reassembly or replacement process.

1. UNDERSTANDING SOLAR PIPELINE SYSTEMS

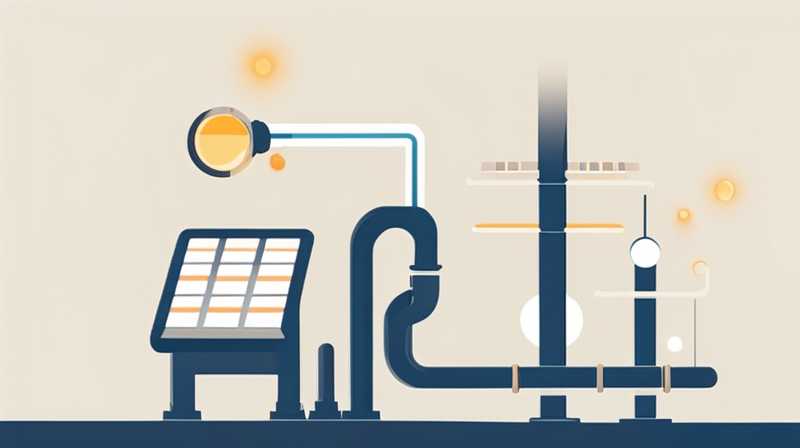

The foundation of effective disassembly is a solid comprehension of the solar pipeline system itself. These systems are primarily employed to harness solar energy, transferring heat from solar collectors to storage tanks or directly to end-use systems. Understanding the role of joints within this framework is fundamental for any disassembly efforts.

Solar pipeline systems consist of various components, including solar collectors, piping, joints, and storage elements. Each component has a specific function and must be compatible to ensure efficiency. Joints are particularly critical as they allow for versatility in design and installation while serving as potential points for leaks or mechanical failure.

Given their importance, recognizing different joint types—such as threaded, soldered, and compression joints—supports a knowledgeable approach to disassembly. Familiarity with these elements empowers one to ascertain the best method for loosening or removing them without damaging adjacent components. Diagrammatic representations or schematic diagrams of systems can also enhance understanding.

2. ESSENTIAL TOOLS AND SAFETY PRECAUTIONS

Prior to any practical disassembly, acquiring the appropriate tools is paramount. Standard tools often required include wrenches, screwdrivers, plumbing tape, and possibly heat sources for certain types of joints. Each tool plays a distinct role, whether in loosening fittings or in securing threads.

Additionally, considering safety measures is non-negotiable. Wearing appropriate safety gear—such as goggles, gloves, and protective clothing—helps mitigate the risks associated with potential injuries. For instance, goggles protect the eyes from debris during disassembly, while gloves prevent cuts from sharp edges. Also, understanding the thermal conditions of the pipeline is crucial, as they may remain hot after operation.

Before starting, review manufacturer specifications for the specific components being disassembled. These guidelines frequently offer insights into proper techniques and precautions tailored to that particular joint type. Ensuring environmentally safe procedures is also vital, as some older systems may employ materials needing careful handling.

3. STEPS TO DISASSEMBLE SOLAR PIPELINE JOINTS

The disassembling process begins with thorough inspection and identification of the joint type. Subsequently, the initialization phase comprises of removing any protective coverings or insulation around the joints, providing easier access to the components.

Loosening threaded joints can often be accomplished using a wrench, while care must be taken to avoid excessive force which may damage the fitting. In certain joints, heat may be necessary to help disengage the connection. This applies particularly to soldered joints, where a propane torch can facilitate the melting of solder for easier withdrawal.

Older systems may feature connections that have rusted or corroded, necessitating additional effort. Using penetrating oil can assist in loosening rusted fittings. Once lubrication has been applied, allow it some time to permeate the threads before attempting to loosen the connection.

As each joint is addressed, careful labeling of components is recommended for subsequent reassembly. Utilizing a visual system for labeling can greatly enhance accuracy, ensuring that components are reinstalled in their original configuration.

4. DEALING WITH COMMON ISSUES DURING DISASSEMBLY

When engaging in this process, it’s common to encounter several challenges. Difficulty in loosening joints often arises due to corrosion or rust, as mentioned previously, leading to extended disassembly times.

Additionally, there may be occurrences of broken components or damaged threads, which necessitates replacing parts rather than merely disassembling them. In these scenarios, seeking assistance from professionals or referencing repair manuals can provide insights into solutions tailored to overcoming such obstacles.

Misalignments can also occur during the remanufacturing phase; thus, ensuring proper alignment of all joints is critical when reassembling. Reviewing the original assembly instructions can provide guidance on achieving effective alignment.

Another common issue is the need to address leaks after reassembling. Upon completion of the disassembly, conducting a thorough testing phase with water or pressure testing tools allows for identifying any leaks that may compromise the integrity of the joint.

Through careful attention to such issues, one can navigate the complexities of disassembling and reassembling solar pipeline joints more successfully.

5. BEST PRACTICES FOR MAINTENANCE AND PREVENTION

Once disassembly and reassembly procedures have been properly executed, establishing maintenance protocols is essential for the longevity of the system. Regular inspections should be scheduled to assess the integrity of joints and pipelines, looking for signs of wear, corrosion, or leaks.

Utilizing high-quality seals and connection materials can also enhance the reliability of the joint systems. Investing in advanced materials may prevent common issues associated with aging systems, such as leaks or deterioration.

Furthermore, keeping the joint system clean from debris, dirt, and sediment not only prevents clogs but also reduces health risks associated with poor operational conditions. Regular cleaning, including clearing debris and flushing the system when necessary, promotes optimal functioning.

Adopting an annual maintenance schedule or consulting with professionals for system evaluations will assure sustained efficiency. Tracking each service session and any findings can help identify recurring issues, leading to informed decisions about upgrades, replacements, or comprehensive overhauls in the future.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING A SOLAR PIPELINE JOINT?

Acquiring the right tools is essential for effectively executing the disassembly of solar pipeline joints. Commonly needed tools include wrenches, which are indispensable for loosening threaded connections, and screwdrivers for detaching clamps or screws securing the joint in place. For certain types of joints where heat is required for disassembly, a propane torch becomes essential, particularly when dealing with soldered connections that must be melted to facilitate removal.

Additionally, owning penetrating oil can prove beneficial when faced with parts corroded or rusted in place. This lubricant can enable easier loosening by permeating the threads, allowing for a less forceful approach that minimizes damage risks. Adjustable wrenches and plumbing tape can provide extra support during the disassembly process, ensuring a snug fit when reassembling. Preparing an organized workspace and verifying the compatibility of tools with specific joint types will streamline the entire process.

HOW SHOULD ONE HANDLE CORRODED OR RUSTED PIPELINE JOINTS?

Dealing with rusted or corroded pipeline joints presents unique challenges that require a strategic approach. Initially, applying a penetrating oil can assist in loosening corroded threads. Allow this oil some time to work its way into the connection, softening any built-up rust. After sufficient penetration time, employ a wrench to gently attempt loosening the bolt or fitting.

If rust remains stubborn, consider using a heat source such as a propane torch. Heating the joint can expand metal, breaking the bond formed by rust, thereby facilitating removal. Caution is necessary to avoid overheating the area, as excessive heat can damage surrounding components or create safety hazards.

In cases where components are beyond salvage, cutting through sections of the pipe may be necessary, although this option should be a last resort due to the potential for more extensive repairs. Whichever method is employed, ensuring the integrity of remaining elements is paramount to maintaining system effectiveness.

WHAT ARE COMMON MISTAKES TO AVOID DURING DISASSEMBLY?

When undertaking the disassembly of solar pipeline joints, several pitfalls can compromise the effectiveness and safety of the process. One common error is insufficient preparation, which may involve inadequate tool selection or neglecting necessary safety equipment. Ensuring all tools and materials are relevant to the specific joint type is critical.

Another prevalent mistake is applying excessive force to loosen joints, which can cause threads to strip or components to fracture. Always seek a controlled approach to disassembly, utilizing penetrating oils and heat as needed does not only reduce the risk of damage but also promotes a safer working environment.

Failure to document the arrangement of joints and individual components during disassembly can lead to confusion during reassembly. Labeling each part provides clarity, minimizing the likelihood of improper reinstallation that compromises system performance. By avoiding these missteps, the disassembly process becomes significantly more effective and safe.

FINAL THOUGHTS

Expertise in disassembling a solar pipeline joint offers insights into the broader discipline of renewable energy systems, emphasizing the necessity of a well-informed approach. Individuals undertaking such tasks benefit from a profound understanding of the components involved, equipping themselves with the required tools and attending to safety precautions. Recognizing potential challenges, such as dealing with rusted fittings or alignment issues, alongside fostering robust maintenance practices enhances the overall lifecycle of solar pipeline systems. In the eco-conscious landscape of renewable energy, mastering the intricacies of solar infrastructure is not simply a technical skill; it ensures the integrity and efficiency of the energy systems that contribute significantly to sustainable practices. As solar technology continues to evolve, possessing the skills for appropriate disassembly and maintenance will empower individuals to support the transition towards cleaner energy solutions effectively. Engaging in meticulous planning, execution, and understanding enhances not only personal expertise but also contributes positively to the community’s shift towards renewable energy. Well-handled disassembly processes mitigate waste and encourage longevity in solar energy systems, paving the path for future innovations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-pipeline-joint-2/