To disassemble a solar light strip panel, follow these steps: 1. Ensure the solar light is powered off and detached from any mounting hardware, 2. Use a screwdriver to remove any screws securing the cover, 3. Gently pry the cover off to access the internal components, 4. Carefully disconnect any wiring and remove the solar panel, battery, or LED strip as needed. The emphasis should be on carefully handling these components to avoid damage.

1. INTRODUCTION TO SOLAR LIGHT STRIP PANELS

Solar light strip panels have emerged as a popular choice for various lighting applications, particularly in outdoor environments. These fixtures harness solar energy during the day and convert it into usable electricity at night, leading to increased energy efficiency and sustainability. With advancements in technology, the design of solar light strip panels has become more sophisticated, offering features like adjustable brightness, motion sensors, and various color temperatures to suit different preferences. Understanding how to disassemble these panels is crucial for maintenance, repairs, or upgrades.

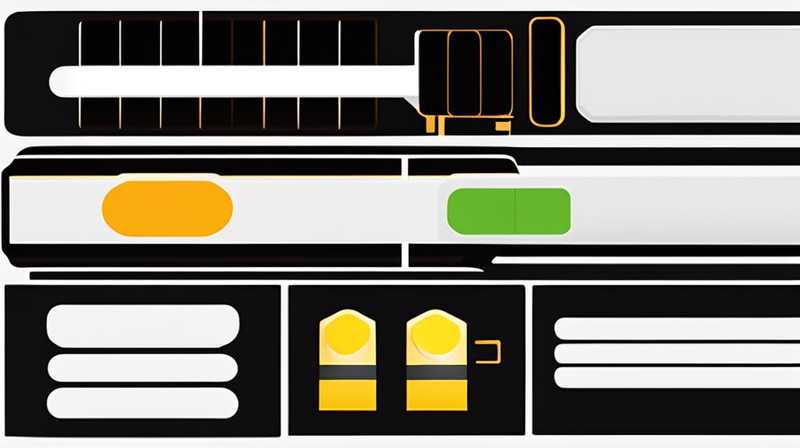

Disassembling a solar light strip panel includes several essential steps that ensure safe access to the internal components. Firstly, a proper understanding of the construction and design of these panels allows an individual to recognize which parts need to be accessed. The majority of solar light strip panels consist of a protective outer casing covering the delicate electronics and battery inside. Thus, careful examination and the right tools are necessary to prevent any inadvertent damage.

In many cases, the disassembly process may be required due to malfunctioning components or the need to replace specific parts. For example, if a battery is no longer charging efficiently, it might need replacing, or if the LED lights are flickering, this could indicate a fault within the strip itself. Therefore, the skillful disassembly of a solar light strip panel can aid in extending its operational lifespan and maintaining its functionality.

2. TOOLS AND SAFETY PRECAUTIONS

Before embarking on the disassembly process, it is paramount to gather the appropriate tools and take necessary safety precautions. A fundamental toolkit should include: 1. Screwdriver set, 2. Pry tools, 3. Multimeter, 4. Safety goggles, 5. Gloves. Having the right tools not only simplifies the procedure but also ensures that the components are handled properly without causing damage.

Safety cannot be overstated when dealing with electrical devices. Firstly, ensure that the solar light strip is powered off and disconnected from any power source to mitigate the risk of electric shock. Additionally, wearing protective gear can safeguard against potential injuries from sharp edges or accidental slips. It is advisable to work in a well-lit environment, ideally one where distractions can be minimized, enabling focus on the task at hand.

When using tools like screwdrivers or pry tools, one should exercise caution to avoid damaging the panels. For instance, applying excessive force while prying open the casing could result in cracks or breaks. Moreover, before proceeding, familiarize yourself with the specific model of the solar light strip panel you are working on. Instructions or guidelines from the manufacturer can prove invaluable, providing insight into any unique features or common issues associated with that model.

3. DISASSEMBLING THE SOLAR LIGHT STRIP PANEL

The procedure for disassembling a solar light strip panel involves several stages. The initial step is to ensure that all components are properly accounted for: 1. Remove the light from its mounting location, 2. Examine the outer casing for screws or fasteners securing it. Many panels will have screws located at the back or sides, which need to be unscrewed carefully.

Once the screws are removed, the next phase entails carefully prying open the outer casing. Employing a pry tool can facilitate this process while minimizing the risk of damage. It is necessary to exert only gentle pressure to avoid breaking the plastic or aluminum housing. While lifting the outer casing, be cognizant of interconnected wiring or components that might hinder the removal.

After the casing is successfully detached, take note of the internal layout of the components. Typically, the internal setup consists of a battery, solar panel, charge controller, and LED strip. Begin with the battery, checking its connections and ensuring it is safely disconnected before proceeding to other components. Utilize a multimeter to diagnose any issues if required—this device assists in determining the power output of the solar panel or the battery condition.

4. REMOVING INDIVIDUAL COMPONENTS

With the outer casing removed, the next step entails extracting individual components from the assembly. Each component serves a vital role in the operation of the solar light strip panel; thus, careful handling is essential. Begin with the solar panel, disconnecting any wiring that connects it to the charge controller or battery. Often, solar panels are held in place with additional screws or brackets, necessitating attention to detail during removal.

The battery can be more challenging to extract. Depending on the model, it may be secured in place by clips or further screws. Handle this part delicately to avoid damaging any connectors, as doing so might require replacement. As the battery is lifted out, examine its condition for any signs of wear or leakage which might indicate the need for a replacement.

Following this, turn attention to the LED strip itself. The LED strip may be connected via soldered connections or connectors. If the model permits, gently disconnect these attachments, being aware of the potential for short circuits at this stage. Documenting the original layout with photographs can assist in the reassembly process later on, thereby ensuring that no components are misplaced.

5. INSPECTING FOR DAMAGE OR WEAR

After disassembly, closely examine each removed component for any signs of damage or wear. This analysis is critical for ensuring that all parts function correctly when reassembled. Start with the solar panel, checking for physical cracks or discoloration that might affect performance. Any discrepancies observed during this phase should be documented, as they will influence decisions regarding repairs or replacements.

Next, inspect the battery for any corrosion on the terminals or bulging, which may indicate a battery failure. If these signs are present, a replacement is necessary, as faulty batteries can significantly reduce the efficiency of the entire solar light assembly. Additionally, investigate any wiring connections for fraying or breakage; damaged wires can be a source of shorts or interruptions in power flow.

The LED strip also requires careful scrutiny. Look for discolored or burnt-out LEDs, which may need replacements. Ensure that the protective coating on the strips is intact, as damage here can lead to moisture ingress and further issues. By taking the time to conduct a thorough inspection, one can ensure that the components remain in optimal operating condition.

6. REASSEMBLY PROCESS

Once the inspection and potential replacement of damaged components have been completed, the next step is the reassembly of the solar light strip panel. This phase can be just as crucial as the disassembly, as improper reassembly could lead to functionality issues. Begin with the LED strip, securely reconnecting any wiring and ensuring that the strips are positioned correctly within the casing.

Following this, the battery should be reinserted, with a focus on ensuring the terminals make solid connections. Double-check the alignment with the mounting clips or screws before securing. It is paramount not to force the battery into position, as this could damage both the battery and the housing.

Once the battery is securely in place, focus on reconnecting the solar panel. Ensure all connections are tight and properly secured. It may be beneficial to perform a quick test with a multimeter to confirm power flow before sealing the case. Lastly, carefully place the outer casing back onto the assembly, securing it with screws while avoiding over-tightening that could lead to cracking.

7. FINAL CHECKS AND TESTING

Before considering the disassembly procedure complete, conduct a series of final checks and tests. Ensure all components are securely in place: 1. Confirm that screws are tightened without excessive force, 2. Inspect for any loose wires or disconnections. Taking these steps minimizes the chance of malfunction when the light is reactivated.

Proceed to activate the solar light, allowing it to charge under sunlight for a duration mentioned in the user manual. Post-charge, test the light’s functionality to confirm proper operation—this includes assessing brightness levels and responsiveness to any built-in sensors. If issues arise at this stage, revisiting connections and the assembly order may be warranted.

In addition, keeping an eye on the operational efficiency of the solar panel is essential, checking whether it charges fully over a period of days. Monitor the behavior of the light during the night, ensuring it properly illuminates as intended. By following these protocols, one can confidently ensure that the solar light strip panel operates optimally after disassembly and reassembly.

8. LONG-TERM MAINTENANCE AND CARE

To maximize the lifespan of the solar light strip panel, establishing a routine for maintenance and care is vital. Consider these key practices: 1. Regular cleaning, 2. Periodic inspections, 3. Protection from environmental factors. Solar panels can accumulate dirt, debris, and dust, which can hinder sunlight absorption. Cleaning the surface of the solar panel periodically with a soft cloth and mild detergent will maintain its efficiency.

Scheduled inspections should take place at least twice a year to identify any potential wear on the components before they escalate into more significant issues. Monitoring battery performance, for instance, can help preempt any failures by allowing for timely replacements.

Environmental factors can also impact the longevity of the light fixtures; harsh weather, excessive humidity, or exposure to debris can deteriorate components. Using protective casings or designing a sheltered area for outdoor lights helps mitigate these effects. Implementing these maintenance strategies will not only enhance the performance of the solar light strip panel but also extend its operational lifespan significantly.

FAQs

HOW LONG DOES A SOLAR LIGHT STRIP PANEL LAST?

The lifespan of a solar light strip panel largely depends on the quality of the components used in its construction. Typically, well-manufactured solar panels can last between 15 to 25 years, while the LED lights may last up to 50,000 hours of usage. Batteries, however, usually need replacement every 2 to 5 years, depending on usage and environmental conditions. Regular maintenance plays a crucial role in prolonging the lifespan of these systems, as it helps identify and address issues such as dirt accumulation on solar panels, frayed wiring, and battery degradation.

WHAT SHOULD I DO IF MY SOLAR LIGHT STRIP PANEL IS NOT WORKING?

If a solar light strip panel fails to function, a series of troubleshooting steps should be taken. Begin by checking whether the solar panel is receiving sufficient sunlight during the day. Examine connections for any loose wires or disconnections. If these appear intact, test the battery’s health with a multimeter; it might be time for a replacement if the battery shows signs of inefficiency. Take note of any visible wear on the LED strips as well, as burnt-out sections will also impact performance. Should all components seem functional yet the panel still does not work, consulting the manufacturer’s guidelines may provide additional insights or steps for resolution.

CAN I REPLACE THE BATTERY IN MY SOLAR LIGHT STRIP PANEL MYSELF?

Yes, replacing the battery in a solar light strip panel is a task that many individuals can accomplish independently. Following the disassembly process outlined previously, locate and remove the existing battery carefully. Make sure to document any wiring configurations to ensure correct reconnections. When selecting a replacement battery, ensure compatibility with the specifications of the original one. Follow the reassembly instructions meticulously, and conduct tests to confirm the functionality of the solar light panel after reinstallation.

Taking proactive measures and performing regular upkeep will enhance the overall efficiency and lifespan of the solar light strip panel. Ensuring satisfaction and reliability in outdoor lighting solutions contributes to sustainable practices in energy consumption. Efficient management of these systems allows for practical utilization of renewable energy sources, showcasing the benefits of solar technology in everyday applications.

In summary, understanding how to disassemble and maintain solar light strip panels is paramount for anyone looking to enhance their outdoor lighting experience. The ability to carefully detach components ensures that functionality is preserved while troubleshooting potential issues. With the right tools and knowledge, this process becomes manageable, resulting in the efficient long-term usage of these sustainable solutions. By promoting regular maintenance, proactive replacements, and proper inspection, one can significantly extend the lifespan and performance of solar light strip panels, ensuring reliable lighting during the night while contributing to ecological sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-light-strip-panel/