To successfully disassemble a solar level gauge port, it is essential to understand several critical factors involved in the process. This task includes 1. gathering necessary tools, 2. understanding the components of the gauge, 3. following a systematic procedure for disassembly, 4. safely handling the components to prevent damage. The first point, gathering necessary tools, involves ensuring that all the required equipment such as screwdrivers, wrenches, and safety gear is readily available. If proper tools are not used, there is a risk of stripping screws or damaging the gauge. Understanding the components of the gauge is crucial, as it allows the individual to identify various parts and functions, ensuring informed handling. Disassembly must follow a systematic approach to avoid confusion or misplacement of components. Lastly, attention to safety will help prevent accidents and injury while working with delicate instruments like the solar level gauge. This comprehensive guide will provide the essential insights needed for a successful disassembly.

1. GATHERING ESSENTIAL TOOLS

Before embarking on the disassembly of a solar level gauge port, it is imperative to assemble all necessary tools and equipment. Having the right tools is vital, as it not only streamlines the disassembly process but also helps prevent potential issues that could arise from using incorrect or inadequate tools. Typical tools might include various sizes of screwdrivers, wrenches, pliers, and even specialized equipment for handling electronic components. Additionally, having safety gear, such as gloves and goggles, is recommended since the process may involve sharp edges or small, easily misplaced parts.

Moreover, an organized workspace is essential. Ensuring that the area is clutter-free and well-lit can significantly enhance efficiency and safety. By keeping tools neatly sorted and laying components out in a recognizable order, one reduces the chances of confusion later. Proper preparation can make a notable difference when it comes time to reassemble the gauge, as components will be easier to locate and manage.

2. UNDERSTANDING COMPONENTS OF THE SOLAR LEVEL GAUGE

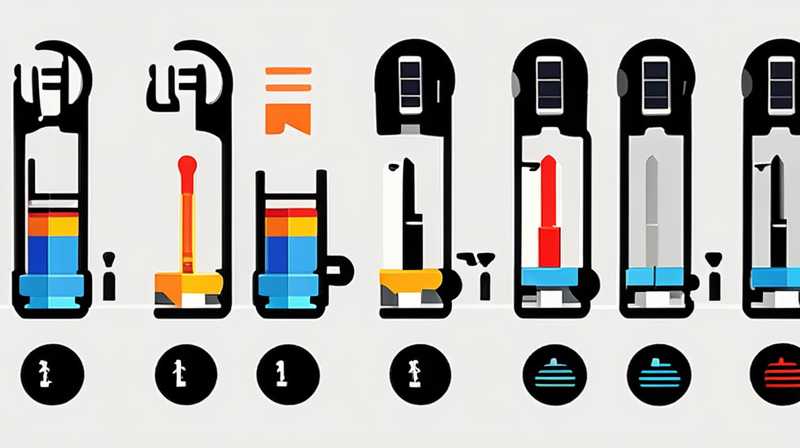

A solar level gauge consists of various components that work harmoniously to measure levels accurately. Understanding each part’s role is crucial during disassembly. At the core of the gauge lies the sensor, which detects changes in light or position. Often, this sensor is coupled with a microcontroller that processes these signals and converts them into readable data. Familiarity with these intricate details helps maintain the integrity of the gauge even while disassembling it.

In addition to the main sensor, there are numerous details such as display panels and battery compartments that warrant attention. The display shows the measured levels, while the battery powers the entire unit. Recognizing how these components interconnect allows for a more methodical separation and prevents any damage. If a component is mishandled during disassembly, it may lead to extra costs or energy loss in future measurements, thereby emphasizing the importance of this knowledge.

3. SYSTEMATIC PROCEDURE FOR DISASSEMBLY

Implementing a systematic procedure greatly enhances the likelihood of a successful disassembly. Starting with the external casing is typically the first step, as this protects the internal components. Carefully remove any screws or clips that secure the casing, ensuring no rhythm is lost. A methodical approach to removing components one at a time is advisable to maintain organization. As each part is separated, it can be laid out in a manner that reflects the original assembly, streamlining the reassembly process later.

Attention to detail cannot be overstated during this phase. Avoid using excessive force when detaching parts; small, delicate components are prone to breakage if treated negligently. Utilize tools with precision and always consult any available schematics or manuals specific to the model. This careful attention will safeguard the integrity of the solar level gauge, ensuring it remains functional upon reassembly.

4. SAFELY HANDLING COMPONENTS

Once the gauge begins to come apart, focusing on the careful handling of each component is essential. Delicate parts, such as circuit boards and sensors, require gentle touch to prevent irreparable damage. Employing anti-static precautions, such as wearing an anti-static wrist strap, can help avoid static discharge, which may harm sensitive electronics.

Proper storage of components during disassembly is another key factor. Utilizing compartmentalized organizers or labeled bags serves to prevent loss or mix-up of parts, ensuring that everything can be easily located during reassembly. As a guideline, it is beneficial to maintain a detailed log or take photographs of the disassembly process. This documentation will provide valuable references if any uncertainties arise later. Through mindful handling and careful organization, the likelihood of encountering challenges during the reassembly phase diminishes significantly.

5. REASSEMBLY TIPS

Following successful disassembly, reassembly awaits attention. Bringing the solar level gauge back together involves reverse engineering the disassembly process. A good practice is to reference any rosters, manuals, or photographs taken throughout the disassembly. Initiating reassembling phase with the internal components is generally advisable, gradually working toward the external casing.

Utilizing the same methodical approach during reassembly is just as important as in disassembly. As components are put back together, ensure that every connection is secure and that all screws are tightened according to the manufacturer’s specifications. This diligence will maintain the functionality of the gauge upon completion. Once reassembled, thorough testing should confirm the gauge operates effectively, validating that the disassembly and assembly process was executed with high precision.

Frequently Asked Questions

WHAT ARE THE COMMON PROBLEMS ENCOUNTERED WHEN DISASSEMBLING A SOLAR LEVEL GAUGE?

When undertaking the disassembly of a solar level gauge, several common hurdles may arise. One frequent issue is the stripping of screws, particularly if the wrong type of screwdriver is used or if excessive force is applied during disengagement. Stripped screws can render components difficult to detach and may necessitate specialized tools for removal, which can further complicate the disassembly process.

Another concern is the potential misalignment of delicate components such as sensors or wiring looms. If these parts become entangled or are not handled with the necessary care, they risk damage, leading to additional repair costs. Ensuring that components are appropriately labeled and organized as they are removed can significantly mitigate the risks associated with misalignment. Ultimately, recognizing these challenges beforehand prepares one for a smoother disassembly process.

HOW CAN ONE ENSURE SAFETY DURING DISASSEMBLY?

Ensuring safety during the disassembly of a solar level gauge is paramount. Wearing appropriate PPE (personal protective equipment), such as gloves and safety goggles, significantly reduces the risk of injury while handling sharp parts or accidentally damaging sensitive components. Engaging with electrical components raises specific safety concerns, including the risk of electric shock. Therefore, attempts should be made to ensure that any power supply is disconnected, and capacitors are discharged prior to handling.

Additionally, maintaining a clean and organized workspace minimizes the risk of accidents. A cluttered environment increases the chances of misplacing parts or injuring oneself while working. Designating a specific area for tools and components, along with having sufficient lighting, not only enhances focus but also encourages a safer working environment. Recognizing these safety precautions ahead of time can facilitate a more secure and efficient disassembly process.

WHAT SHOULD BE DONE IF COMPONENTS ARE DAMAGED DURING THE PROCESS?

Damage to components during the disassembly of a solar level gauge can be frustrating, yet it is crucial to remain calm and methodical. Assessing the extent of the damage is the first step in addressing this issue. If minor components like screws are stripped or misplaced, sourcing replacements from hardware stores or directly from the manufacturer can often be a viable solution.

However, if significant components such as sensors or circuit boards are compromised, replacing them may be necessary. Many manufacturers provide customer support or parts sales, which can assist in locating appropriate replacements. It is advisable to document the damage and take photographs if necessary, as this information may be beneficial when consulting technical support or seeking replacements. Ensuring that all security protocols were followed during disassembly might prevent these issues from arising in the future and lead to smoother operations.

In summary, successfully disassembling the solar level gauge port requires careful planning, a systematic approach, and an emphasis on safety. Adhering to these principles will not only facilitate the disassembly process but also ensure that the reassembly phase occurs without major issues. By gathering necessary tools, understanding the components, following a logical procedure, and storing parts thoughtfully while focusing on safety, individuals can carry out this task with confidence. Investing time in preparation and learning about the device increases the overall efficiency and effectiveness of the project. With careful attention to these facets, the chances of damage decrease significantly, thereby allowing for the solar level gauge to be maintained or repaired effectively.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-level-gauge-port/