To effectively disassemble a solar intelligent measurement and control instrument, you will need to follow a systematic approach that ensures the device’s internal components are handled with care. 1. Preparation of the workspace, 2. Identification of tools required, 3. Understanding the device’s layout, 4. Detachment of individual components, 5. Safely storing parts for reassembly. The preparation phase is crucial; ensure that the workspace is clean and free of distractions to avoid losing small parts or damaging delicate components.

1. PREPARATION OF THE WORKSPACE

Creating a suitable environment is the first step toward dismantling complex electronic devices. A clutter-free area designated solely for this task enhances focus and aids in organization. Proper lighting is essential, as it allows the user to see small screws, connectors, and printed circuit boards (PCBs) clearly. It is advisable to use a mat or surface that protects both the device and any tools being used.

Beyond that, a container for screws and small parts is indispensable. Using a magnetic tray or small compartments helps maintain organization and prevents loss of essential components. Also, consider having cleaning supplies on hand — like compressed air for removing dust and debris from internal mechanisms, which could hinder performance when the device is reassembled.

2. IDENTIFICATION OF TOOLS REQUIRED

The task of disassembling a solar intelligent measurement and control instrument necessitates specific tools to avoid damage. Standard tools include screwdrivers of various sizes, possibly including Phillips and flat-head types. Depending on the instrument’s design, a Torx screwdriver may also be required to tackle specialized screws.

Additionally, employing a pair of tweezers can aid in handling small components without risk of contamination or damage. For instances where components are snugly fit, a plastic spudger or prying tool is invaluable; this tool allows the careful separation of tightly joined parts without scratching or breaking them. It is critical to ensure that all tools are in good condition, as worn-out tools may slip and cause accidents during the disassembly process.

3. UNDERSTANDING THE DEVICE’S LAYOUT

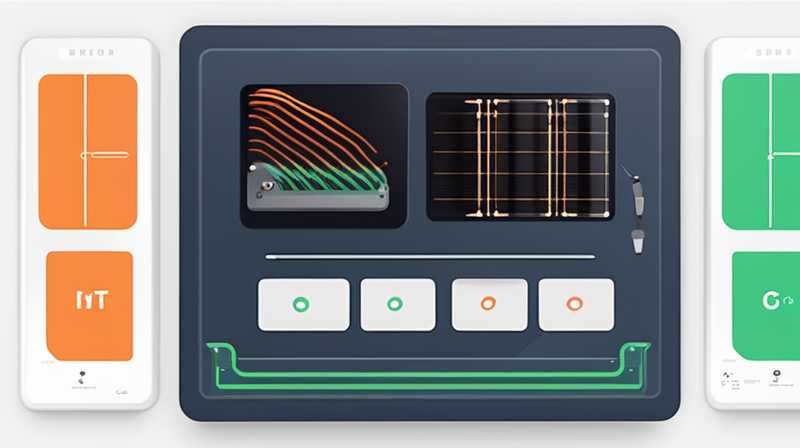

Before diving into disassembly, comprehending the internal architecture of the solar intelligent measurement and control instrument is vital. Examine the exterior carefully for access points, seams, and potential indicators of component interfaces. Often, manuals or service guides provide schematic diagrams that illustrate the arrangement of internal parts.

Taking pictures or making sketches of the device’s layout can streamline reassembly, ensuring every part finds its rightful place. Familiarity with the circuitry is particularly essential since electronic components are usually interconnected in intricate ways. Understanding which parts correspond to sensors, measurement units, and control mechanisms enables a more informed approach to disassembly, minimizing risks of short circuits or other mishaps.

4. DETACHMENT OF INDIVIDUAL COMPONENTS

With preparation and understanding of the layout established, the actual dismantling can commence. Start by carefully removing any casing or covers—pay attention to any screws securing these panels. Upon removing the outer housing, you are likely to encounter various internal components, such as batteries, circuit boards, and sensors.

When disconnecting these elements, ensure that all cables and connectors are handled gently. Pulling too forcefully can damage the fragile wires, resulting in irreversible damage. Identifying connectors and using the right amount of leverage to detach them is paramount. Documenting the order of detachment is also helpful, especially for complex interconnected systems.

5. SAFELY STORING PARTS FOR REASSEMBLY

Once the individual components have been carefully removed, attention must shift to the safeguarding of these delicate parts. Labeling each component with corresponding notes helps simplify the reassembly process. Using small zip-lock bags or containers to group similar parts or components significantly aids organization.

Moreover, storing components away from electronics that may generate static electricity is critical. Using anti-static bags for sensitive parts, such as circuit boards or integrated circuits, helps ensure that they remain undamaged until reassembly. A methodical cataloging system will prevent confusion and save time when putting everything back together.

FREQUENTLY ASKED QUESTIONS

HOW DO I KNOW IF I HAVE THE RIGHT TOOLS FOR DISASSEMBLING THE INSTRUMENT?

Selecting the appropriate tools hinges on the device’s specifications. Refer to the owner’s manual or repair guides, which should include a list of necessary tools. Typically, for solar intelligent measurement and control instruments, a precision screwdriver set, pliers, and plastic pry tools are essential. Additionally, organizing the workspace with tool selections that match the type and size of screws or components encountered enhances efficiency. Specialized tools for delicate electronics, such as anti-static wrist straps, should also be considered to prevent electrostatic discharge (ESD).

WHAT SHOULD I DO IF A COMPONENT DOES NOT COME APART EASILY?

If a part seems stuck, do not resort to excessive force, as this could cause irreparable damage. Instead, double-check for any hidden screws or clips that may be holding it in place. Utilizing a gentle prying motion with a plastic spudger can often provide the necessary leverage to safely detach components. If tension persists, revisiting the manufacturer’s guidelines or looking up service manuals can provide clarity on the proper detachment method. Should the challenge continue, consider consulting forums or communities specializing in electronic repairs for additional advice tailored to your specific device.

IS IT SAFE TO DISASSEMBLE MY DEVICE IF I’M NOT AN EXPERT?

While many individuals successfully undertake electronic device repairs without formal training, a certain level of caution is essential. Establishing a well-organized workspace and gathering the necessary tools can significantly mitigate potential risks. Familiarity with the device’s functions will aid in making informed decisions during disassembly. If the device includes sensitive components that could be damaging to handle, or if unsure about specific procedures, it may be wise to consult a professional or refer to detailed, step-by-step guides available online. By doing so, the likelihood of mishaps is greatly reduced.

FINAL REMARKS ON DISASSEMBLY PROCESS

Engaging in the disassembly of a solar intelligent measurement and control instrument creates opportunities for hands-on learning and potential upgrades. Taking the time to master each step builds not only practical skills but fosters a deeper appreciation for the technology that drives modern instrumentation. Proper preparation entails organizing tools, setting a tidy workspace, and understanding the layout of the device. Mastery of each subcomponent promotes confidence during the disassembly, and enables straightforward reassembly. Ultimately, safeguards against damage enhance longevity and ensure optimal performance of the device. By embracing the disassembly process, individuals cultivate a sense of empowerment, paving the way for future technical endeavors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-intelligent-measurement-and-control-instrument/