To disassemble a solar hidden valve core, one must follow a systematic approach involving specific tools, safety precautions, and a detailed understanding of the components involved. 1. Gather necessary tools and safety gear, 2. Familiarize yourself with the valve components, 3. Carefully remove the housing to expose the core, 4. Extract the valve core without damaging surrounding parts. This process requires precision and care, particularly during the removal of sensitive components. When disassembling, ensure that you do not force any parts apart, as this can lead to irreparable damage or make reassembly more difficult. Understanding the valve configuration will aid in effective disassembly.

1. TOOLS REQUIRED

Prior to embarking on any mechanical disassembly, it is imperative to gather the appropriate tools. The types of tools required for this specific procedure include a ratchet, extensions, socket sets, and a valve core tool. Each tool plays a vital role in the overall success of the disassembly process. Furthermore, safety gear such as goggles and gloves is also essential to protect oneself from accidental injuries while working with small or sharp components.

The ratchet and socket set allow one to remove the screws and bolts securely fastening the valve body. A valve core tool specifically designed for this purpose assists in extracting the valve core systematically. Another critical instrument that may be necessary is a pair of needle-nose pliers, useful for maneuvering into tight spaces or grasping small components. Having these essential tools ready will contribute significantly to a smoother disassembly process.

2. SAFETY PRECAUTIONS

Safety considerations are paramount when dealing with mechanical components. Prior to initiating disassembly, it is essential to ensure that pressurized systems have been adequately depressurized and that any residual materials are contained within an appropriate environment. Wearing protective eyewear will safeguard against any unexpected debris or the dangers associated with valve components, including hydraulic fluids that may accidentally leak.

Additionally, working in a well-ventilated area is advisable, especially if chemicals are involved in the valve system. One should also establish a clean workspace where tools and parts can be organized to minimize the risk of losing components during the disassembly. By adhering to these safety measures, potential hazards can be significantly reduced.

3. EXAMINING VALVE COMPONENTS

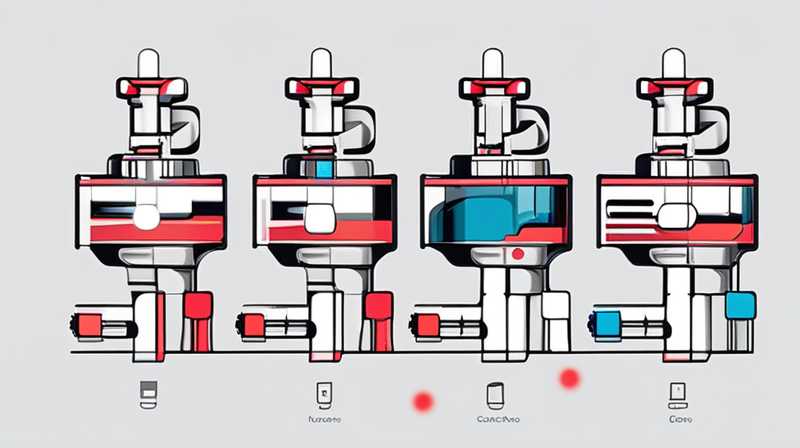

Prior to disassembly, gaining a thorough understanding of the hidden valve’s components is vital. Every valve typically consists of a body, a bonnet, a valve core, and various seals and springs. The body serves as the main structure housing the core, while the bonnet usually contains locking mechanisms or access points for adjustments. The core itself is the fundamental part governing the flow or regulation of the fluid, and its design can vary based on the application of the valve.

Recognizing the different parts and their functionality can simplify the disconnection process and facilitate effective handling. Moreover, being aware of how each component connects assists in avoiding any potential mishaps during the removal procedure. This knowledge also aids in the reassembly process, providing invaluable context for ensuring everything is put back in its proper place.

4. REMOVING THE HOUSING

Once all necessary preparations have been made, commence by cautiously removing the valve housing. This involves loosening and taking out the screws or bolts securing the housing to the valve assembly. Using the ratchet and appropriate socket, apply steady pressure ensuring that you do not strip the screws in the process. If resistance is encountered, utilize penetrating oil to loosen corroded screws gently.

After successfully detaching the housing, practical steps should be taken to isolate the valve core from the remaining components. It is crucial to store all screws and removed hardware in a designated container. This organization will prevent misplacement and facilitate a more straightforward reassembly when the time comes.

5. EXTRACTING THE VALVE CORE

With the housing removed, the valve core is now accessible. Employing the valve core tool, position it around the exposed core and rotate counterclockwise to unscrew it from the socket. Be cautious with the pressure being applied; excessive force may damage both the core and the valve seat. It may help to lightly wiggle the core while unscrewing it to help loosen any potential obstructions.

After extracting, inspect the valve core and surrounding areas for any debris or damage that may compromise functionality upon reassembly. Understanding whether the core is reusable or requires replacement is integral for proper maintenance and optimal operation of the valve in question.

6. MAINTAINING COMPONENT INTEGRITY

Throughout the disassembly process, maintaining component integrity is critically important. Any scratches or deformation might lead to leaks or inhibit proper function once reassembled. Careful handling of each part and an awareness of how they interact will mitigate the risk of any unwanted damage. As these components often include seals and intricate mechanisms, ensuring they are preserved in ideal conditions is paramount.

Cleaning the extracted components, especially any seals or threads, can significantly improve reassembly precision and overall performance during subsequent usage. Appropriate cleaning techniques might involve using a non-abrasive cloth to avoid scratching surfaces or employing specific cleaners suited for the materials used in the valve construction.

7. REASSEMBLY PROCESS

After disassembly and any necessary repairs or replacements are made, the reassembly process begins. Following the initial disassembly steps in reverse is a good approach, but it is imperative to pay attention to the torque specifications for screws and bolts to prevent loosening over time. O-rings and seals should be inspected and replaced if signs of wear or damage are present.

Alignment is also crucial during reassembly. Any misalignment can lead to function failure or leaks post-reassembly. It is advisable to double-check that all components fit securely, and that moving parts operate smoothly without obstruction. This careful and deliberate approach to reassembly will ensure that the valve performs effectively once repaired.

8. TESTING VALVE FUNCTIONALITY

Prior to putting the valve back into operation, a thorough test of the entire system should be conducted. This procedure often involves checking for any leaks or assessing the valve’s ability to regulate flow correctly. Pressuring the system gradually can reveal any unnoticed flaws that might compromise safety or functionality.

Upon completing a successful test, document the entire disassembly and reassembly process, including any findings or adjustments made. Such records are invaluable for future maintenance and provide insights into the system’s history, which might be useful during subsequent repairs or inspections.

COMMONLY ASKED QUESTIONS

WHAT IS A SOLAR HIDDEN VALVE CORE?

Solar hidden valve cores are specialized components integrated into various fluid systems, particularly those utilizing solar energy for operational efficiency. The purpose of these cores involves regulating the flow of fluids within a closed loop while ensuring minimal heat loss. Their design is tailored to provide reliable performance under both high and low-pressure conditions. Because they are often concealed within an assembly, access to them requires a more meticulous approach to disassembly and reassembly compared to more exposed components. Understanding their functionality is essential for maintenance and effectively prolonging their operational life.

HOW OFTEN SHOULD I SERVICE MY SOLAR VALVE SYSTEM?

Ideal servicing frequency varies based on usage patterns, environmental stresses, and specific system designs. Many experts recommend conducting a thorough servicing every one to two years as a general guideline. However, more frequent inspections may be warranted depending on the operational conditions faced by the system. Factors such as exposure to extreme temperatures or a high frequency of usage can necessitate a more proactive approach to maintenance. Regular checks on seals, the valve core, and associated components will help in identifying potential issues early and maintaining overall performance efficiency.

WHAT SIGNS INDICATE A VALVE CORE NEEDS REPLACEMENT?

Several indications signal that a valve core may require replacement or serviced attention. Commonly observed signs may include leaks around the valve area or irregularities during fluid flow, such as unusual resistance or blockages. Furthermore, a noticeable loss in pressure when operating the system can indicate potential vulnerabilities within the core mechanism. If the system exhibits any unusual sounds such as hissing or grinding, it may also imply that components are worn or not functioning optimally. Periodic inspections should allow for timely identification of these symptoms, ensuring that efficient operation is preserved.

Valves serve as critical components in various machinery and systems, especially in solar applications where effective fluid management is of utmost importance. Mastering the disassembly of a solar hidden valve core involves meticulous preparations, a solid understanding of the components involved, and careful execution of both disassembly and reassembly tasks. By gathering the right tools and prioritizing safety, individuals can successfully navigate the intricacies of this process. Following through with dedicated inspection and testing ensures that operational integrity is maintained post-repair, and ultimately prolongs the functionality of the entire system. Proper maintenance practices not only foster longevity but also enhance system performance, underscoring the importance of comprehensive knowledge in mechanistic operations. Continuing education about such components is crucial as innovations and best practices evolve within mechanical engineering disciplines, ensuring practitioners remain adept in managing increasingly complex technologies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-hidden-valve-core/