1. Disassembling a solar copper pipe joint requires a systematic approach. Proper tools, such as a pipe wrench, adjustable wrench, and safety goggles, are essential (1). Ensure the solar system is fully depressurized before starting (2). Identifying the joints and connections properly is crucial to avoid damaging components during the process (3). Understand the types of fittings: soldered, threaded, or compression (4). Each type requires a different method for safe disassembly, ensuring the pipe’s integrity and preventing leaks upon reassembly (5). Attention to detail in each step will not only simplify the process but will also ensure safety and efficiency when reassembling the system.

1. UNDERSTANDING COPPER PIPE JOINTS

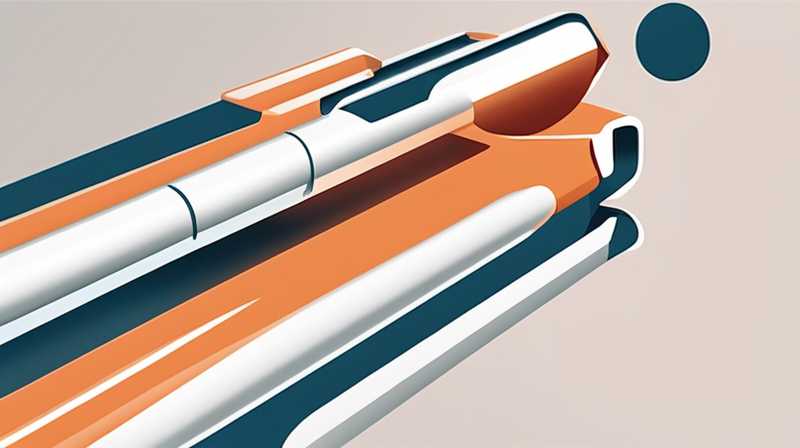

Solar thermal systems often utilize copper piping due to its excellent thermal conductivity and resistance to corrosion. The various types of copper joints used in these systems include soldered, screw threaded, and compression fittings. Each connection type employs different methods for attachment, necessitating specific disassembly techniques. Recognizing these differences is imperative since misidentifying a connection can lead to unnecessary damage.

Soldered joints involve melting rods to bond pipes together, creating a permanent fix that cannot be easily undone without specialized tools. In contrast, compression fittings allow for simpler disassembly; they rely on a mechanical grip and can be detached with minimal effort. Understanding the type of joint will enable you to approach disassembly with the right tools and techniques, significantly impacting efficiency and safety in the procedure.

2. TOOLS REQUIRED FOR DISASSEMBLY

Equipping oneself with the right tools is crucial for any disassembly task. Essential tools for removing a solar copper pipe joint include pipe wrenches, adjustable wrenches, soldering torches, and safety goggles. Each tool has a distinct role, aiding in the safe and efficient breakdown of connections.

The pipe wrench is indispensable for gripping and turning pipes, providing the necessary torque to loosen tight fittings. An adjustable wrench offers versatility when dealing with various bolt sizes and is especially useful for nuts and compression fittings. To safely handle any potential fumes or sparks generated during the disassembly, wearing safety goggles is mandatory to protect the eyes from debris. Ensuring you have these tools ready before starting will foster a seamless and secure operation.

3. SAFETY PRECAUTIONS

The process of disassembling a solar copper pipe joint inherently includes hazards that need to be addressed. Recognizing potential risks helps mitigate accidents and health hazards. One major precaution involves ensuring that the solar system is depressurized before initiating disassembly. This promotes safety and prevents any sudden leaks or bursts that could result in injury.

Another vital aspect is protecting oneself by wearing personal protective equipment (PPE), including goggles and gloves. The risk of cuts from sharp edges or burns from hot components necessitates an increased level of awareness and preparation. Following safety guidelines not only adheres to industry standards but also cultivates a safe working environment, encouraging accuracy and efficiency in the disassembly process.

4. DISASSEMBLING SOLDERED JOINTS

The most complex joints to disassemble are soldered connections, which require a careful methodology. Begin by identifying the joint and ensuring that the system is fully depressurized. Utilizing a soldering torch, focus on heating the joint until the solder begins to soften – careful attention is paramount as overheating can damage the copper pipe.

Once the solder is molten, apply a slight twisting motion with the pipe wrench to separate the joint gently. It’s vital to have a catch basin or rag ready to collect any remaining solder or fluid during this procedure. After disassembly, thoroughly clean the ends of both pipes to remove any residual solder and debris, preparing them for reassembly or replacement. This meticulous process is essential for maintaining the integrity of the copper pipes and ensuring a secure connection when rejoined.

5. DISASSEMBLING COMPRESSION JOINTS

Compared to soldered joints, compression fittings offer a more straightforward disassembly process. Begin by identifying the fitting type, and locate the compression nut. Using an adjustable wrench, loosen this nut without unnecessary force to prevent stripping its threads. As the nut loosens, you will notice that the compression ring (also known as a ferrule) collapses, allowing the pipe to slide out.

Once disconnected, it is important to examine the condition of the compression ring; if damaged, it should be replaced prior to reassembling the joint. This method reduces time and effort spent and is often favored in scenarios that require routine maintenance or adjustments. Proper technique in this area guarantees that the pipes remain in good working order, extending the longevity of the solar system.

6. DISASSEMBLING THREADED JOINTS

Threaded joints feature grooves that help connect pipes in a secure manner. For these types of connections, the methodology involves using an appropriate-sized pipe wrench. Begin by firmly gripping the larger fitting while applying rotational force in the opposite direction to unthread it.

As you unwind the joint, it may be beneficial to apply a penetrating oil if corrosion between the threads occurs. This helps facilitate the loosening of stubborn fittings. Take care not to apply excessive force, as this can lead to damaging the threads of the pipe. Following removal, assess threads for any wear before reassembly, ensuring a robust seal during future operations.

7. MAINTAINING COPPER PIPES POST-DISASSEMBLY

After successfully disassembling the solar copper pipe joint, maintenance becomes paramount for future operations. Cleaning the copper pipes is one of the most effective measures for ensuring longevity. This procedure includes removing residues, oxidation, or corrosion build-up before reconnecting the components.

Inspecting each joint for damage is equally important. Any deformation or weakness in the pipe may lead to leaks upon reassembly. Replace any damaged segments with new copper piping, ensuring to select high-quality materials that withstand temperature variations. Following practices like these avails the overall system health significantly, enhancing response rates and efficiency.

FREQUENTLY ASKED QUESTIONS

HOW DO I KNOW IF MY SOLAR PIPE JOINT IS LEAKING?

Detecting a leak in a solar pipe joint may require vigilance in inspecting both exterior and interior systems. Signs of leaks often present as visible moisture around joints or fittings. A pressure test can also be effective—shutting off water flow and observing whether the system maintains pressure over time can indicate if there are undetected leaks. Listening for any hissing could also point toward escaping gases or liquids. Finally, don’t overlook visual inspections that highlight rust or erosion along pipes, as impending failure may be indicated through these warning signs.

WHAT TO DO IF A JOINT IS STRIPPED OR DAMAGED DURING REMOVAL?

If a joint becomes stripped or damaged, the priority should be assessing the extent of the damage. Stripped threads might still be usable with a thread sealant, but if the structural integrity is compromised, replacing components becomes necessary. Utilizing a thread tap tool can reestablish threads in some cases. However, for severe damage, cutting and replacing that section of the pipe with new material will ensure that the system remains functional and efficient in the long run. In critical situations, consulting a professional can avert risks associated with improper repairs.

CAN I REUSE OLD COPPER PIPE JOINTS?

Reusing old solar copper pipe joints is often feasible but requires thorough inspection and cleaning to ensure reliability. Visual examination should focus on signs of wear or corrosion that could compromise usability. Components displaying minimal wear can typically be repurposed, whereas those exhibiting degradation or deformation should be replaced. Additionally, soldering and sealing surfaces may require refurbishing to create effective joints. Incorporating careful evaluation will prolong the lifespan of the solar system as reused components can offer significant cost savings when handled correctly.

To summarize, disassembling a solar copper pipe joint is a complex yet manageable task requiring appropriate tools and expertise. Ensuring safety through depressurization and protective gear is paramount. Recognizing the type of joint and employing the right technique will facilitate efficient disassembly while maintaining the integrity of the components. Attention to detail, thorough inspections, and care during handling will further prepare pipes for subsequent reassembly, which is crucial for continued functionality of solar systems. These procedures require not just mechanical skill but also a commitment to maintaining quality workmanship throughout the process. Following established methods increases the likelihood of successful reassembly, thus ensuring optimal performance in solar heating applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-copper-pipe-joint/