Disassembling a solar charging connector requires a systematic approach to ensure safety and maintain the integrity of the components. 1. Ensure you understand the type of connector, 2. Gather appropriate tools, 3. Follow a step-by-step disassembly routine, 4. Maintain a clean workspace. Each of these points is essential for successful disassembly. For instance, understanding the type of connector involved is crucial; different connectors may have unique locking mechanisms. This includes recognizing if any screws, clips, or specific release levers must be engaged. Proper tools are also necessary to avoid stripping screws or damaging the connector housing. Following a methodical process minimizes confusion and maximizes efficiency. Lastly, a clean workspace prevents losing small components and allows for a focused effort on the disassembly task.

1. UNDERSTANDING THE SOLAR CHARGING CONNECTOR

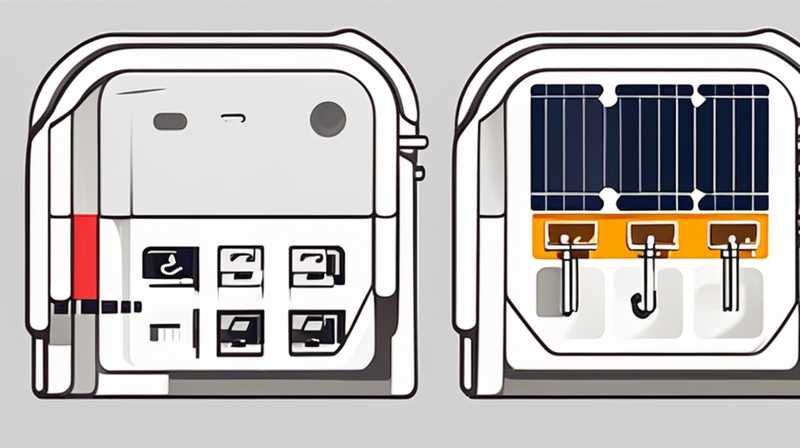

Disassembling any electronic component begins with a thorough understanding of the connector design. Solar charging connectors come in various types, such as MC4, Anderson Powerpole, or SAE connectors. Each type features a specific locking mechanism or method of attachment that must be understood prior to any disassembly attempts. Identifying the connector type is vital, as each has unique properties.

For example, MC4 connectors, widely used for their reliability and weather resistance, typically utilize a two-piece design that locks securely. One must be aware of how this locking mechanism operates. A good approach is to conduct research or consult the manufacturer’s documentation. Understanding how to release or disengage the locking mechanism will eliminate unnecessary damage to the components and facilitate a smoother disassembly process.

Familiarizing oneself with the electrical specifications and the components housed within the connector further aids in the disassembly process. Solar charging connectors often contain delicate wiring or sensitive electronic components that may be affected by mishandling. Thus, understanding the layout and function of these internal elements can help prevent mishaps.

2. GATHERING TOOLS AND MATERIALS

Before embarking on the task of disassembling a solar charging connector, having the right tools is essential. Utilizing the proper tools prevents damage and ensures a safe disassembly process. Commonly needed tools may include a small flathead screwdriver, Phillips screwdriver, wire cutters, and pliers.

Having a small flathead screwdriver allows for prying open locked components without causing damage to the plastic housing of the connector. Similarly, a Phillips screwdriver will be useful for any screws that need removal. Wire cutters can be handy in situations where the connector is permanently affixed and cannot be delicately pried apart. Keeping these tools organized and within reach speeds up the disassembly process significantly.

Moreover, additional materials such as a clean workspace and small containers for small parts are beneficial. Creating a dedicated space minimizes distractions and significantly decreases the chances of losing small components. It is prudent to have label stickers or notepads handy to document any removed parts and their respective locations or connections, thus aiding in reassembly.

3. DISASSEMBLY STEPS

With the correct understanding of the connector type and necessary tools in hand, one can begin disassembling the solar charging connector. Following a structured approach simplifies the overall process and reduces potential errors. The disassembly process can vary slightly depending on the connector type; however, a basic outline generally applies across most types.

Start by removing any external protective caps or covers. These are designed to safeguard the internal components and may simply slide off or require a gentle twist to remove. Once these parts are out of the way, inspect the connector for any visible screws or latches. If screws are present, utilize the appropriate screwdriver to remove them before proceeding. Ensure to keep the screws in a container to prevent loss.

If the connector utilizes a snap-fit design without visible screws, identify any latches or tabs that may need pressing or releasing. Employ the small flathead screwdriver, applying gentle pressure to lift locks and tabs. It’s crucial to avoid excessive force, as this can easily lead to plastic breakage or irreversible damage to the connector housing.

Following the release of external components, it is time to examine the internal wiring and connect the terminals. Carefully detach any wires from their terminals while keeping note of their configurations. Documenting the original connections and configurations at this stage will greatly facilitate the reassembly process later. Utilize the wire cutters if necessary to cut any cables that are soldered or tightly secured. This step must be done with caution, ensuring that the connections are flowing smoothly without twisting or damaging the wire strands.

4. TROUBLESHOOTING COMMON ISSUES

As one navigates the disassembly process, encountering obstacles is common. Being prepared for potential issues is key to a successful disassembly. Some common problems include stuck components, stripped screws, or cables that refuse to detach easily.

In the case of a stuck connector component, you may gently wiggle it back and forth while applying minimal upward pressure. Sometimes, a gentle tap can loosen stuck parts, but never apply excessive force, as doing so can lead to damage. If reaching the internal components is problematic, troubleshooting by inspecting for hidden screws, clips, or misalignments may help.

Stripped screws can be an especially frustrating hurdle. If the head of a screw becomes stripped, it may render it challenging or impossible to remove. Using rubber bands can provide extra grip on the screw head for removal. Alternatively, one may try to drill a small hole in the center of the screw to create a new slot for a screwdriver. Always exercise caution during this process, as aggressive drilling can damage surrounding components.

Lastly, if you encounter difficulty detaching cables, inspect the connectors for any locks or safety mechanisms. Forcing cables can lead to damage, so taking a moment to examine can prevent further issues.

5. SAFETY CONSIDERATIONS

Disassembling solar charging connectors does require certain precautions. Safety should always be prioritized to prevent injury and ensure that components remain functional after disassembly. First and foremost, ensure that no power source is connected to the solar panel or battery system while performing disassembly tasks. This step minimizes the risk of electrical shock or short circuits.

Wearing safety glasses is advisable to protect the eyes from any accidental debris or component fragments that may break during disassembly. Additionally, gloves can provide a cushioned grip on components, making it easier to manipulate parts without concern for slipping. These safety measures are necessary to promote an efficient and accident-free workspace.

Furthermore, after disassembling the connector, it is essential to avoid touching the internal components with bare hands. Oils and contaminants from fingertips can adversely affect electronic connections. Instead, hold components by their edges or use tweezers.

Finally, always double-check the condition of components before and after disassembly. If any debris is present, carefully clear it before reconnecting or utilizing the solar charging system again. Implementing such safety considerations ensures a seamless disassembly experience and promotes the longevity of equipment involved.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING A SOLAR CHARGING CONNECTOR?

When disassembling a solar charging connector, having the appropriate tools on hand is essential. The most common tools needed include a small flathead screwdriver, Phillips screwdriver, wire cutters, and pliers. While the flathead screwdriver aids in prying open locked components, the Phillips screwdriver is necessary for any screws present. Wire cutters are essential if the wires are tightly secured or soldered.

Keeping these tools organized and within reach can greatly facilitate the disassembly process. Additionally, small containers to hold screws and other volatile parts can prevent loss and streamline the workflow. Creating a clean workspace ensures a focused effort on the task and lessens the chance of losing components. Having the correct tools is a critical aspect of successfully and efficiently disassembling solar charging connectors.

HOW CAN I AVOID DAMAGING COMPONENTS DURING DISASSEMBLY?

To minimize the risk of damaging components during the disassembly of a solar charging connector, one should take a systematic and careful approach throughout the entire process. Begin by thoroughly understanding the type of connector, including its locking mechanisms and configurations. Familiarity with how the components interact aids in disassembly without excessive force that could lead to breakage.

Tool selection is equally important. Using the appropriate tools—such as a small flathead screwdriver for prying open locks and a proper size Phillips screwdriver for removing screws—ensures that pressure is applied effectively. Always check for visible screws or clips, avoiding confusion regarding how components come apart.

When handling internal wiring and connections, note each component’s placement. Keeping a detailed log of the configuration can prevent accidental damage and mistakes. Lastly, maintaining a clean workspace can prevent the unnecessary loss of small parts and allow for effective component handling.

WHAT SHOULD I DO IF A COMPONENT IS STUCK AND WON’T COME APART?

A common situation encountered during the disassembly of solar charging connectors is dealing with stuck components. When faced with such a challenge, patience and caution are essential; applying excessive force can cause irreversible damage to the connectors. Start by examining the connector for any screws, clips, or hidden latches that may secure the stuck part.

If slated components are not budging, try wiggling them gently while applying minimal pressure in the opposite direction. This gentle movement may help to loosen stuck parts. A gentle tap with a soft tool can also help dislodge components without applying too much force.

If the component remains stubborn, consider using a lubricant designed for electronic parts sparingly. Apply a small amount to the junction where it’s stuck, allowing the lubricant to seep before retrying to disengage. Always remember that if resistance persists, taking a moment to reassess the connector’s design will often reveal a solution without causing damage.

Carefully orchestrating the disassembly of a solar charging connector requires a comprehensive understanding of the components involved. Identifying the type of connector, selecting the appropriate tools, and adhering to a detailed disassembly routine are paramount. Remaining aware of the potential challenges one may encounter and implementing safety precautions fosters a smooth disassembly process and protects the integrity of the components. Practicing diligence and meticulousness throughout prepares one to reassemble the connections expertly, ensuring that the solar charging system operates effectively post-disassembly.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-charging-connector/