Disassembling a solar barrel requires careful attention to detail and a step-by-step approach. 1. Understand the components, 2. Gather the necessary tools, 3. Follow safety protocols, 4. Document the process are essential steps in ensuring a successful disassembly. A detailed examination of the solar barrel’s structure will reveal various parts, such as the collector panel, the storage tank, and the piping. Each component may have specific fasteners that need to be addressed appropriately.

The tools required typically include a screwdriver set, adjustable wrenches, safety goggles, and gloves to prevent injuries. A thorough understanding of the assembly layout will be beneficial, especially when attempting to reassemble later. Additionally, documenting the process through annotations or photography ensures that no steps are missed, preventing potential issues when putting the system back together. The disassembly process often involves several stages, and patience along with adherence to safety protocols will ultimately lead to success.

1. UNDERSTANDING THE SOLAR BARREL

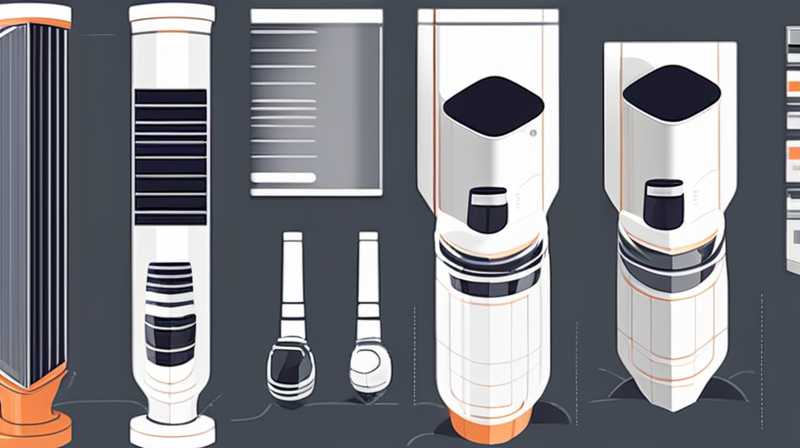

The solar barrel is a vital component in solar energy systems, functioning primarily as a heat collector and storage unit. Its design consists of several layers, including insulation and structural materials tailored to enhance energy efficiency. The inner components, such as the solar collector plates and connecting pipes, play crucial roles in heat conversion and retention, making it essential to comprehend them before undertaking the disassembly.

The first step in this analytical process involves identifying each part. The solar collector, usually located on top, captures sunlight and converts it into thermal energy. This energy is transferred to a fluid, commonly water or a glycol mixture, circulating through the system. Understanding the interplay of these components is crucial for anyone looking to maintain or upgrade a solar barrel. Furthermore, knowing the materials used in construction will aid in choosing the right tools for disassembly. Different metals, plastics, and composites may require varying degrees of care when disconnected, thus preventing damage to both the components and the user during the process.

2. GATHERING THE NECESSARY TOOLS

Equipping oneself with the right tools significantly influences the disassembly procedure. The most commonly needed tools include a set of screwdrivers that can handle different screw types, an adjustable wrench, pliers, and safety equipment. Each tool serves a defined purpose, and using them correctly will safeguard against unnecessary damage during navigating the disassembly process.

Safety gear such as gloves and goggles is indispensable. These tools protect the user from potential injuries caused by sharp edges or falling components. Understanding how to employ these tools is equally important; misuse can complicate the disassembly, leading to injuries or damaging components that would otherwise be usable. Selecting tools that are ergonomically designed can facilitate better handling and reduce physical strain during the lengthy process, ensuring comfort while maintaining efficiency.

3. FOLLOWING SAFETY PROTOCOLS

Engaging in the disassembly of a solar barrel mandates adherence to strict safety procedures. Before initiating the process, it is imperative to disconnect all power sources to avoid electrical hazards. This precaution not only secures personal safety but also protects valuable equipment from damage during disassembly. Understanding how to safely disconnect various components is crucial; for instance, a fluid drain should be performed using specific methods to avoid spills or exposure.

Layered safety measures further enhance the disassembly approach. Including informing bystanders about the ongoing procedure and maintaining a clean workspace can mitigate the risk of accidents. Creating a clear path for accessing the solar barrel and ensuring all tools are within easy reach will enhance efficiency while keeping safety in focus. These protocols collectively transform the disassembly environment into one that is both productive and secure.

4. DOCUMENTING THE PROCESS

Documentation during the disassembly of a solar barrel is essential for efficient reassembly and future maintenance. Taking careful notes or photographs helps keep track of the order of assembly and component positions. Each fastener removed should be noted, especially if various sizes or types are involved; labeling them as they are taken out can save time and confusion later on.

The use of a digital camera or smartphone to capture photos at each step can serve as a visual guide. Such records allow individuals to revisit the original configuration of components, simplifying the reassembly process. This not only reduces the chances of errors during reinstallation but also enhances comprehension of the system’s design and functionality, ultimately contributing to improved maintenance and longevity of the equipment.

5. DISASSEMBLY STEPS

As one prepares to initiate the disassembly of the solar barrel, it is imperative to follow a systematic approach. Starting with the external components, such as the casing or panels, is advisable. These parts typically need to be removed first to grant access to critical internal sections. A series of screws, clips, or bolts usually secure these panels; thus, an appropriate set of tools will facilitate their removal.

Once external components are removed, the focus shifts to disassembling the internal components. Components like the collector plate must be approached with care, as they are often connected to the piping and heat transfer fluids. Rigorously following the documented structure becomes essential to ensure that all connections are intact throughout the disassembly.

6. HANDLING COMPONENTS

Throughout the disassembly process, having a clear plan for handling each component is vital. Components should be organized logically to maintain clarity and facilitate easy reassembly. Use separate containers labeled appropriately for screws, washers, and other small parts, preventing loss and confusion in the future.

Special care must be given to fragile components, including collector plates and tubing. These parts may be susceptible to bends or fracturing if mishandled. Understanding how to support these components safely during removal can prevent potential damage that may render them unusable.

7. REASSEMBLY PREPARATION

Once the disassembly is complete, reassembly planning becomes paramount. This phase begins with the inspection of each component for wear or damage. By assessing the state of components before reinstallation, an individual can identify any necessary replacements or repairs beforehand, assuring integrity in the reconnected system.

Creating an organized workspace and re-applying documentation skills from the removal process will foster an efficient reassembly. Recollecting the notes and images taken during disassembly will guide the user in reintroducing each part accurately back into the barrel, minimizing the risk of errors and subsequent issues.

8. MAINTENANCE AND LONGEVITY

Understanding the nuances of disassembly lays the groundwork for effective maintenance practices. Regular checks and preventative maintenance can ensure optimal functionality of the solar barrel, prolonging its life. Familiarity with the disassembled components allows for easier identification and addressing of potential issues that may arise.

Regular inspections throughout the operational life of the solar barrel can catch problems early when they are more manageable. This proactive approach minimizes downtime and contributes to the system’s overall efficiency. Practicing preventive care will yield substantial benefits, not only for the efficiency of energy conversion but also in reducing long-term maintenance costs.

FREQUENTLY ASKED QUESTIONS

HOW LONG DOES IT TAKE TO DISASSEMBLE A SOLAR BARREL?

The time required to disassemble a solar barrel can vary significantly based on several factors, including the size of the barrel, the complexity of its design, and the user’s experience level. Typically, for individuals familiar with the process, disassembly could take anywhere from a few hours to a full day. Those less experienced might find the task takes longer, as they may need to pause frequently to consult documentation or seek guidance.

To facilitate a smoother process, it would be wise to dedicate an entire day for disassembly, especially if additional maintenance or assessments are planned. Take time to familiarize oneself with the components and layout prior to starting the disassembly process, as this can greatly reduce the likelihood of encountering unexpected issues that may elongate the time frame. Making careful notes or visual records throughout the disassembly will also speed up potential future reassembly efforts.

WHAT ARE COMMON MISTAKES DURING DISASSEMBLY?

Common pitfalls during the disassembly of a solar barrel can lead to significant complications and even damage. Improper labeling of components, failing to document the order of removal, and neglecting to follow safety precautions are frequent occurrences. When individuals do not label small parts, they run the risk of creating confusion when trying to reassemble the unit.

Additionally, a lack of attention to safety measures may cause physical harm or damage to components. It is imperative to have a well-structured approach in place, prioritizing documentation, labeling, and remaining vigilant about safety protocols. Preemptively addressing these common mistakes can streamline the disassembly process, ensuring a higher likelihood of success both in removal and eventual reassembly.

CAN I REASSEMBLE A SOLAR BARREL WITHOUT PROFESSIONAL HELP?

Yes, an individual can typically reassemble a solar barrel without professional assistance, provided they have accurately documented the disassembly process and are confident in their understanding of the components. However, familiarity with the system is crucial for a successful outcome. Those who take detailed notes and photographs during disassembly will find their task significantly easier during reassembly, as they can reference these materials to guide their steps effectively.

Nonetheless, if one encounters uncertainties or complexities, seeking advice from a knowledgeable source may provide critical insights that further enhance the reassembly process. Consider consulting with experienced professionals or referencing instructional materials to gain additional confidence in undertaking a successful reassembly without professional intervention.

Mastering the disassembly and recommissioning of a solar barrel entails a well-planned approach, a thorough understanding of the components involved, gathering the appropriate tools, and adhering to safety measures. With detailed documentation throughout the process, individuals can efficiently tackle both disassembly and future maintenance, ensuring the longevity and optimal performance of their solar energy systems. Proper organization, respect for components, and a commitment to safety can transform what may seem an overwhelming task into a systematic and fulfilling experience. The knowledge gained from successfully navigating this process can empower individuals in both their current undertaking and future projects.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-barrel/