To effectively disassemble a solar ball valve, attention must be given to specific steps crucial for ensuring the valve’s integrity during and after the process. 1. Understanding the valve’s components, 2. Preparing the necessary tools, 3. Executing the disassembly procedure, 4. Ensuring proper handling and maintenance. It is vital to recognize that the solar ball valve plays a significant role in controlling the flow of fluids in various renewable energy applications, typically solar heating systems.

UNDERSTANDING THE VALVE’S COMPONENTS

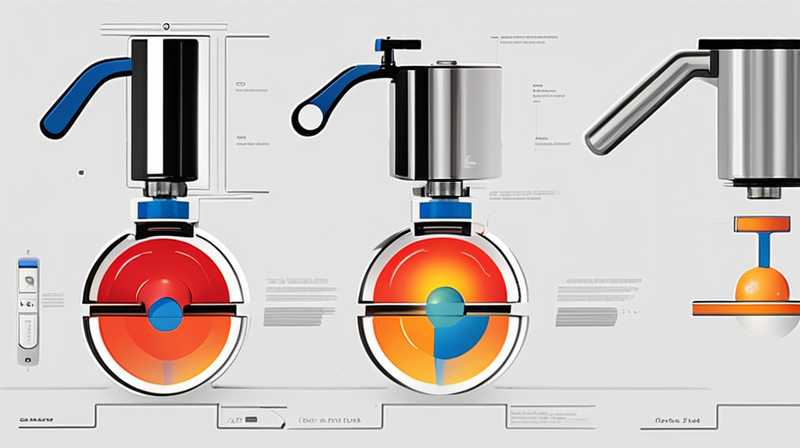

Solar ball valves function by utilizing a spherical disc that moves within the valve body, enabling or obstructing flow based on its position. The primary components include the valve body, the ball, and the stem. The valve body is crafted from durable materials to withstand external pressures. Understanding each component’s purpose aids in the task of disassembly, ensuring that no parts are damaged during the process.

In addition to these primary components, one should be aware of secondary elements such as seals and gaskets that ensure a tight closure. These components can degrade over time, leading to leaks if not properly maintained. By recognizing these aspects before disassembly, one can mitigate risks and prepare for the effective reassembly of the valve.

PREPARING THE NECESSARY TOOLS

Prior to initiating the disassembly process, it is essential to gather all necessary tools. A comprehensive toolkit for this task typically includes adjustable wrenches, screwdrivers, pliers, and possibly a torque wrench for specific applications. Each tool has a particular role, and ensuring they are in good condition will facilitate a smoother disassembly procedure.

Moreover, having protective gear is vital during this process. Safety goggles and gloves will reduce the risk of injury, especially if the valve has been under pressure. Preparing the workspace is equally important; a clean and organized area reduces the chance of losing small components or tools during the disassembly process and helps maintain focus on the task at hand.

EXECUTING THE DISASSEMBLY PROCEDURE

Initiating the disassembly begins with ensuring that the valve is free from any fluid pressure. If the valve is still pressurized from ongoing use, it poses significant risks of injuries and potential damage to the components. Gradually relieve the pressure by opening downstream valves, allowing fluid to escape safely.

Once the pressure is confirmed to be zero, the next step is to detach the valve from its installed location. This might involve loosening bolts or fittings that connect it to the solar heating system. Care must be taken here to prevent stripping any threads on the fittings.

As you proceed, carefully inspect each part as it is removed. Be mindful of the orientation and position of components, which is crucial for accurate reassembly. Labeling components or documenting their arrangements can be invaluable later on, particularly if someone else will be reassembling the valve.

ENSURING PROPER HANDLING AND MAINTENANCE

Once all components have been detached, it’s important to maintain each part correctly. Cleaning the components thoroughly prevents dirt and debris from interfering with the valve’s functionality. Utilize appropriate cleaning solutions that are compatible with the valve’s material.

Inspect each part for signs of wear, especially seals, gaskets, and the ball itself. Determine if any components require replacement before reassembly. Properly handling each item prevents scratches and wear, extending the lifespan of the valve and ensuring function when reinstalled.

After cleaning and inspection, storing all components in a safe place will be integral until reassembly can occur. Organizing parts methodically will aid in tracking where each component resides, minimizing confusion as the reinstallation phase approaches.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD SOLAR BALL VALVES BE DISASSEMBLED FOR MAINTENANCE?

Regular maintenance is crucial for the efficiency of solar ball valves. The recommended frequency varies widely based on environmental conditions. In regions with harsh weather, it’s advisable to inspect and possibly disassemble the valve annually. However, in more temperate climates, every two to three years may suffice.

During these inspections, it’s key to check for leaks, assess the integrity of seals, and ensure that moving parts operate smoothly. Neglecting the valve can lead to significant issues such as reduced efficiency or complete system failure, which are detrimental not only to the solar setup but also to financial investments into renewable energy.

WHAT TOOLS ARE ESSENTIAL FOR DISASSEMBLING A SOLAR BALL VALVE?

Equipping oneself with the right tools is essential for an effective disassembly. At a minimum, a pair of adjustable wrenches, various screwdrivers (including flathead and Phillips), and pliers are crucial. Furthermore, depending on installation specifics, you might require a torque wrench for specific fittings or nuts.

Having these tools handy streamlines the disassembly process and allows for corrections as challenges arise. Remember to have protective gear on hand, such as gloves and goggles, to safeguard against potential injuries during the procedure.

CAN I DISASSEMBLE A SOLAR BALL VALVE MYSELF OR IS PROFESSIONAL HELP REQUIRED?

While many individuals can disassemble a solar ball valve themselves, guidance is encouraged if one is unfamiliar with plumbing components. Comprehensive understanding of the valve and appropriate tools can lead to successful disassembly without professional assistance.

However, for individuals who lack experience in this area, seeking help from a professional is advisable. This not only ensures proper handling of the equipment but also lowers the risk of missteps that can lead to further complications down the line.

In summation, handling the disassembly of solar ball valves demands careful attention to detail and awareness of each component, tools, and techniques involved. Proper preparation and knowledge guarantee that the task can be completed proficiently while safeguarding the system’s integrity. Keeping meticulous records and orienting parts for later assembly is just as critical as the disassembly itself. If you maintain the valve and its components correctly, the system will function effectively for years, yielding substantial benefits from the solar application. Proper care reinforces the sustainability goals of utilizing renewable energy—and thereby extends the life of the system, all while ensuring it operates at peak performance. Always remember that safety should take precedence; engaging professional services when uncertain may save time and resources in the long run. Respecting the intricate balance of components will ultimately lead to a successful reinstallation, maintaining both the efficiency and functionality inherent in solar technologies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-ball-valve/