1. Be well-informed about the tools and materials needed, ensure proper safety precautions are taken, carefully take note of the assembly order, and work in a suitable environment with ample light. Effective disassembly begins long before the wrench meets the valve, as being organized can streamline the process significantly. 2. Understand the valve’s construction and working mechanism, and identify the various components before disassembly. Familiarizing oneself with the solar angle valve’s function can mitigate the risk of components breaking or misplacing them during the procedure. 3. Maintain focus on the task at hand, helping to prevent damage or loss of components. Many individuals underestimate the importance of concentration, but it is crucial for avoiding costly mistakes. 4. Adhere strictly to directions to reassemble the parts accurately, ensuring the effectiveness of the valve in future applications. These operational precautions will promote success in disassembling and reassembling the solar angle valve effectively.

1. UNDERSTANDING THE SOLAR ANGLE VALVE

Solar angle valves serve an essential role in solar water heating systems, functioning as key components that control the flow of water in such setups. Understanding the fundamentals of these valves is the first step towards knowledgeable disassembly. Solar angle valves typically regulate water flow based on temperature changes, allowing for efficient heating and cooling processes. They often have an internal mechanism that allows them to open or close depending on environmental conditions, and thus they must be properly maintained to ensure their functionality.

In the context of solar energy systems, the efficiency of these valves can have a direct impact on overall system performance. A malfunctioning valve can lead to inadequate heating, leading to wasted energy and increased costs for users. Consequently, understanding the inner workings of the solar angle valve offers insights into its essential functions and the importance of effective maintenance.

2. TOOLS AND MATERIALS REQUIRED

Before embarking on the disassembly, it is vital to gather all necessary tools and materials. A set of basic tools typically includes a wrench, screwdriver, pliers, and a clean workspace, ensuring that the process is as efficient as possible. Each tool plays a significant role in disassembling components without causing unnecessary damage or wear.

Additionally, preparing specific materials such as a clean cloth, container for small parts, and perhaps lubricant for re-assembly is essential. Using a clean cloth prevents contaminants from entering valve systems during disassembly. The organization of small components in a dedicated container ensures that no pieces are lost, an occurrence that could complicate reassembly considerably.

3. SAFETY PRECAUTIONS

Prior to starting the disassembly process, one must recognize the importance of safety precautions. It is crucial to turn off the solar water heater system to prevent accidental burns and water flow, which could cause injury or damage during the procedure. Proper ventilation is important if any solvents or lubricants are utilized, as chemical exposure can pose health risks.

Wearing protective gear is also advisable, including gloves and goggles. This gear acts as a safeguard against sharp edges or potential chemical splashes during the disassembly process. By adhering to safety measures diligently, practitioners can mitigate risks and maintain a secure environment while ensuring the integrity of the valve and adjacent components.

4. DISASSEMBLY PROCESS

Now that the preparatory phase is concluded, one can proceed to the actual disassembly of the solar angle valve. The process begins by ensuring you have access to the valve by removing any encasing or insulation that may obstruct the component. Such preparations provide unobstructed access and enable a thorough examination of the valve situation.

The next step entails loosening and removing the bolts or screws that secure the angle valve in its place. Using the appropriate wrench size for the bolts prevents rounding them off or causing other damage, which can complicate reassembly. Patience is key during this phase, as applying too much force may lead to breakage. Once loosened, carefully place the removed bolts and screws into the designated container.

After removing the securing hardware, the valve itself will be free to detach from its fittings. Gently wiggling the valve free is suggested, as this motion can dislodge any seals or gaskets without damage. Once removed, inspect the component closely for any worn or damaged parts to inform decisions for required replacements.

5. INSPECTING COMPONENTS

Following disassembly, the inspection of each component is critical. Valves consist of various parts, including stems, O-rings, and other gaskets, all which may wear over time. Scrutinizing these pieces for cracks, wear, or corrosion informs the need for repairs, replacements, or even a complete valve replacement if major issues are detected.

If parts appear intact but dirty, clean them gently without using corrosive chemicals that may damage sensitive materials. Drying thoroughly after cleaning is essential, as moisture can lead to performance issues or rust during reassembly. Comprehensive inspections coupled with thoughtful cleaning practices promote the longevity of components once reassembled.

6. REASSEMBLY PREPARATIONS

Once inspections are completed, preparing for reassembly warrants attention. Ensure that all cleaned and inspected parts are ready before beginning to reassemble the valve. This proactive approach facilitates a smoother and more streamlined process.

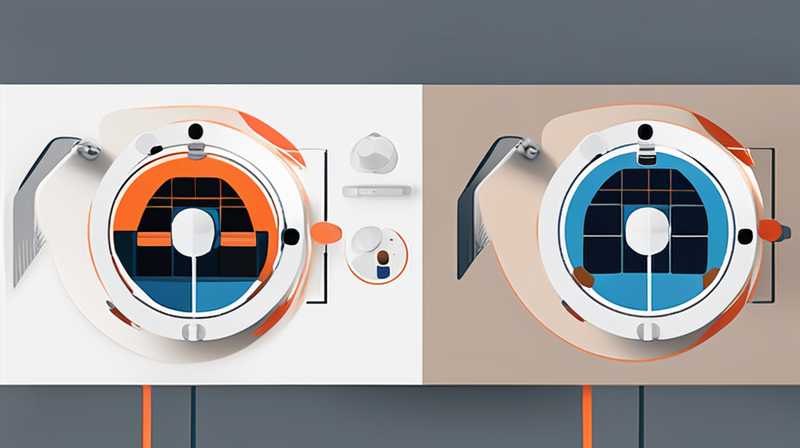

It is wise to refer to the assembly guidelines or diagrams if available, to ensure that every piece is returned to its original position correctly. Organizing items in the sequence of assembly drastically reduces the risk of overlooking parts or forgetting the assembly order. By attending to these reassembly preparations, one sets the stage for successful completion.

7. THE REASSEMBLY PROCESS

Recomposing the various valve components requires patience and care. Begin by placing the main body of the valve back into position, aligning it with the corresponding fittings. This alignment is critical for ensuring a proper seal and correct function once the system is operational again.

Next, one must secure the valve using bolts or screws that were previously removed. Applying even pressure is important to avoid misalignment, and employing a torque wrench can assist in achieving the correct tension. Over-tightening can lead to damage, while insufficient tightening could create leaks, negatively impacting performance.

Once the valve is in place, utilizing lubrication on O-rings and gaskets is prudent. Lubrication helps in creating an efficient seal, thereby preventing leaks as well as making disassembly easier in future maintenance tasks. Final inspections for proper alignment, functionality, and the tightness of fittings must occur before reactivating the system.

8. TESTING THE SYSTEM

Upon successfully reassembling the angle valve, conducting a thorough test ensures that all systems work as intended. Restarting the solar heater and allowing the system to reach operational temperatures provides insight into the efficacy of the reassembled valve. Observing for leaks and measuring water temperatures at different points help gauge performance.

If any anomalies occur through this testing phase, revisiting assembly steps to troubleshoot is essential. Such diligence ensures that the valve operates with maximal efficiency and safety, addressing any potential failures head-on. Both prolonged testing and consistent monitoring post-disassembly indicate the overall success of the process, ultimately leading to sustenance in performance.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR ANGLE VALVE?

A solar angle valve is a crucial component in solar water heating systems, utilized to regulate water flow based on temperature changes within the system. These valves assist in both the heating and cooling processes, allowing for improved efficiency in solar energy use. Understanding their operation provides insight into why proper maintenance and occasional disassembly is necessary. Problems with these valves can lead to inefficiencies and increased costs, making it imperative to ensure they function correctly. Regular checks and professional insights can help maintain optimal operating conditions.

HOW CAN I DETERMINE IF MY SOLAR ANGLE VALVE NEEDS REPLACEMENT?

Several signs indicate that a solar angle valve may require replacement. First, visible leaks or corroded components typically signal that a thorough inspection is needed. Furthermore, if the valve fails to open or close mechanically as required, or if the temperatures in the system are inconsistent, these can also point toward failures within the valve. Regular maintenance checks are fundamental in identifying issues early. By monitoring performance and seeking professional advice whenever issues arise, homeowners can ensure prolonged functionality of their solar systems.

CAN I DISASSEMBLE AND REASSEMBLE THE valve MYSELF?

Yes, individuals with suitable basic knowledge and tools can disassemble and reassemble a solar angle valve themselves. However, it is crucial to adhere to safety procedures, ensure all components are organized, and understand the potential for accidentally damaging parts. Comprehensive guides and resources are available that detail the processes involved. Although DIY efforts can save costs, individuals should seek professional help if they feel uncertain at any point. Proper training or assistance can significantly improve the outcome of the procedure while preventing mistakes.

In summary, understanding the solar angle valve’s construction, preparing the proper tools and safety measures, and following a meticulous disassembly and reassembly process are critical. By ensuring diligent inspection and testing, homeowners can successfully maintain this essential component of their solar heating systems, ultimately contributing to long-term efficiency and performance. The knowledge imparted through this exploration emphasizes the importance of proper maintenance procedures, enabling effective care for solar angle valves.

Embracing these practices will not only sustain their functionality but also empower individuals to manage future challenges, optimizing the utilization of renewable energy in their homes. Proper maintenance nurtures a proactive approach that can lead to greater energy savings and lower expenses in the long run.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-solar-angle-valve/