To disassemble the side of a solar barrel, a sequential approach involving careful assessment, appropriate tools, and safety precautions is essential. 1. Gather necessary tools and materials, 2. Assess the structure and design of the solar barrel, 3. Follow systematic disassembly instructions, and 4. Ensure safety measures are adhered to throughout the process. Each of these points plays a critical role in effectively removing components without causing damage or compromising safety. This process should begin with gathering the appropriate tools, including screwdrivers, socket sets, and safety equipment.

1. GATHER NECESSARY TOOLS AND MATERIALS

Before embarking on the disassembly of the solar barrel’s side, it is imperative to gather a comprehensive set of tools. An adequate toolbox is essential for facilitating the process, particularly those tools that are specifically designed for different types of screws and fittings. Common tools include a flathead and Phillips screwdriver, as well as a socket wrench set. Each of these tools serves a distinct purpose in the disassembly process. The screwdriver may be needed for removing various screws, while the socket wrench aids in loosening nuts or bolts that may secure the side panel.

In addition to primary tools, having a method for organizing screws and other tiny components is beneficial. Plastic containers or magnetic trays can be used effectively to prevent loss, which can become a significant issue during disassembly. It is prudent to label these containers based on the order of disassembly or the location of the screws to make reassembly easier. Maintaining an organized workspace alleviates potential frustrations and contributes to a smoother process.

2. ASSESS THE STRUCTURE AND DESIGN OF THE SOLAR BARREL

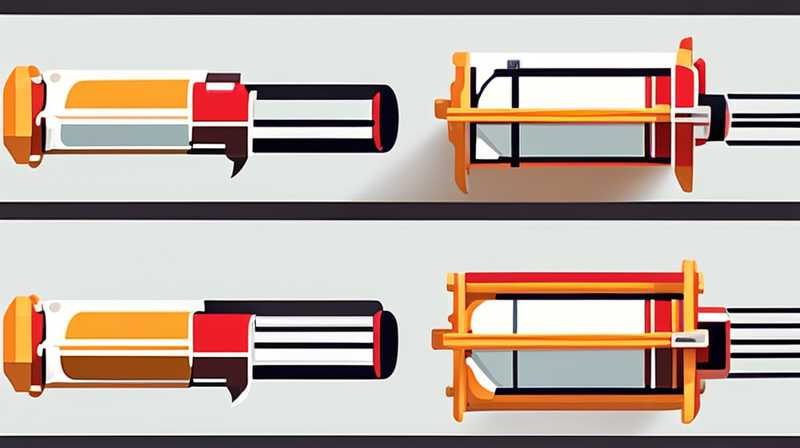

Understanding the design of the solar barrel is critical prior to any physical disassembly. Solar barrels, depending on the manufacturer, may have a unique configuration that dictates the method of disassembly. Thus, reviewing any available documentation or instruction manuals is advisable. These documents frequently outline specific procedures relevant to the model, which can aid significantly in achieving a seamless disassembly.

Furthermore, closely examining the solar barrel upon visual inspection allows one to identify screws, bolts, or clips that might be engaging the side panel. Understanding the design also allows for a better grasp of how various components are interconnected. Take note of any electrical components, sensors, or wiring that may need to be disconnected before the side can be removed. Documenting these components can be invaluable if reconnection or reassembly becomes necessary later on.

3. FOLLOW SYSTEMATIC DISASSEMBLY INSTRUCTIONS

Once the tools and knowledge of structure are in hand, the systematic process of disassembly can commence. Starting at the top or the back of the barrel is often recommended, working your way towards the side that requires removal. Removing screws and connectors in a logical order prevents confusion and reduces the risk of damaging any components. Pay attention to any specific requirements the manufacturer might indicate about panel removal; they might use proprietary fittings or clips that differ from standard fixtures.

If at any point resistance is encountered, avoid forcing components apart. This could lead to structural damage. Instead, review the area for any overlooked fasteners or connections. If necessary, consult the product documentation or seek assistive resources online that may provide solutions to common disassembly challenges. Documentation can also serve as a checklist, ensuring that every necessary step has been completed before attempting to remove the side panel.

4. ENSURE SAFETY MEASURES ARE ADHERED TO THROUGHOUT THE PROCESS

The final step of this process encompasses ensuring the user’s safety throughout the entire disassembly procedure. Safety goggles, gloves, and proper footwear should be utilized to protect against components that may fall or sharp edges that may present themselves. Moreover, if any electrical or high-voltage components are present, ensuring the barrel is properly de-energized before commencing work is crucial. Disconnecting any power supply should be the first action taken to avoid accidents.

Always remain aware of your surroundings, especially if disassembling outdoors or in a cluttered environment. Keep the workspace well-lit to see any small parts clearly and to avoid any missteps that could result in injury. By adhering to these safety measures, the disassembly process can proceed efficiently and effectively, with a lower risk of accidents or damaged components throughout the journey.

FAQS

WHAT TYPE OF TOOLS DO I NEED TO DISASSEMBLE A SOLAR BARREL?

To effectively disassemble a solar barrel, it’s crucial to have the right tools on hand. The most commonly used tools include a range of screwdrivers, specifically both flathead and Phillips types. The choice of screwdriver often depends on the screws used in your specific model, so it is important to review the configuration beforehand. Additionally, a socket wrench set is essential if there are bolts securing panels or structures, enabling easier loosening and removal.

Safety gear is equally important when undertaking any disassembly task. Protective goggles help guard against debris that may be dislodged during the process, while gloves provide grip and protection from sharp edges. Using magnet trays and small containers to sort screws and components can also be beneficial. This organizational strategy not only simplifies the process but also helps to ensure that nothing goes missing, making reassembly more manageable. Overall, equipping oneself with both the necessary tools and safety gear is essential for a seamless disassembly experience.

HOW DO I SAFELY DISCONNECT ELECTRICAL COMPONENTS IN A SOLAR BARREL?

Connecting and disconnecting electrical components within a solar barrel should be approached with caution to prevent both system damage and personal injury. The first and foremost step involves disconnecting any power supply by turning off the system at the circuit breaker or appropriate safety switch. Only after ensuring that no electricity is flowing through the system can work proceed on the electrical components.

Next, it’s advisable to document the location of each wire and connection prior to disconnection. Utilizing color-coded labels or a camera to take detailed photographs can significantly aid the reassembly effort later. Be gentle when pulling wires from their connectors, as excessive force may cause damage to the connections or wires themselves. Also, make certain to examine for any visible signs of wear or corrosion before disconnecting components, as this could pose an additional risk during the disassembly process. Following this structured approach ensures that the process remains as safe as possible while entirely effective.

WHAT SHOULD I DO IF I ENCOUNTER STUCK PARTS DURING DISASSEMBLY?

Encountering stuck parts during the disassembly of a solar barrel can be frustrating, yet there are multiple methods to address this challenge effectively. First, review the disassembly plan and ensure that you have removed all screws and bolts that may be securing the component in question. Minor components can sometimes be hidden or overlooked, leading to unnecessary force being applied to stuck parts.

If a part remains stuck even after checking for obstructions, applying gentle pressure is often the best approach. Using a rubber mallet or tapping the part lightly may help to loosen any friction without causing damage. If the part is still resistant, consider using lubrication such as a penetrating oil that can seep into joints and facilitate loosening. Patience is paramount in these scenarios; forcing parts apart can result in breakage. Always prioritize methodical evaluation and gentle handling to preserve the integrity of the barrel during disassembly.

To ensure a structured approach to disassembling the side of a solar barrel, it is vital to gather the right tools, understand the design of the barrel, follow detailed instructions, and uphold safety measures. Each of these steps contributes cohesively to achieving a successful disassembly process, providing a clear path while minimizing risks. Planning and methodical execution facilitate an improved experience during the disassembly journey, allowing for any subsequent repairs or maintenance to be conducted with confidence. Safety, too, plays an integral role, ensuring that the risks associated with such a process are significantly mitigated. Fostering an awareness of these elements enables individuals to approach solar barrel disassembly with assurance and competence, whether for troubleshooting, upgrades, or repairs. Adapting these practices builds a foundational understanding that can benefit a variety of situations involving solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-side-of-the-solar-barrel/