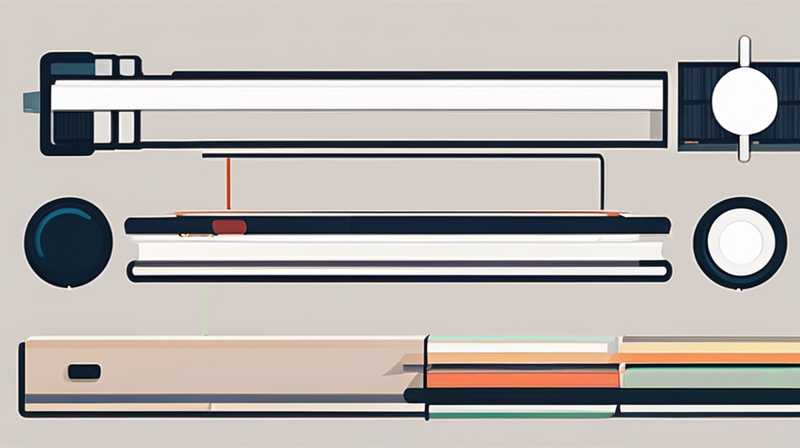

1. To disassemble a movable solar light strip requires careful attention to the structural components and the tools needed to avoid damaging the device. 2. Begin by removing any screws or bolts securing it in place. 3. Next, gently pull apart the housing, ensuring that the internal wiring remains intact. 4. Lastly, disconnect the solar panel and battery units for safe handling. The process demands a systematic approach, ensuring all parts are accounted for and that the light strip can be reassembled seamlessly if necessary.

1. INTRODUCTION TO MOVABLE SOLAR LIGHT STRIPS

Movable solar light strips represent a versatile solution to outdoor lighting, combining energy efficiency with portability. As these lighting systems become increasingly popular, enthusiasts often find themselves curious about the mechanics behind them. Understanding how to disassemble these strips empowers users to maintain, repair, or repurpose their units as needed. By delving into the construction and inner workings, individuals can also become more adept at troubleshooting issues that may arise over time.

These strips generally consist of a few primary components: the light-emitting diodes (LEDs), a solar panel, a battery for energy storage, and the housing that serves as a protective outer layer. The light’s design allows it to withstand varying environmental conditions while providing a reliable light source powered by renewable energy. Innovations in technology mean that these devices can be lightweight yet durable, permitting a variety of applications.

2. TOOLS REQUIRED FOR DISASSEMBLY

Before initiating disassembly, gathering suitable tools is critical. Common tools needed include a screwdriver set, pliers, a non-conductive pry tool, and safety goggles. Each tool plays a distinct role, making the disassembly process smoother and safer.

TOOL SELECTION

Choosing the correct screwdriver is essential since solar light strips can have screws made from different materials, including stainless steel or plastic. A flathead screwdriver may cater to larger screws, while Phillips heads handle cross-headed screws. Pliers facilitate the removal of stubborn components, ensuring that brute force does not damage delicate parts.

Using a non-conductive pry tool can help prevent electrical shorting during the disassembly. This straightforward device allows for the gentle separation of components without risking damage to plastic or electronic elements. Safety goggles protect the eyes from any flying debris or accidental contact with sharp edges during the process.

3. SAFETY CONSIDERATIONS

Engaging in any form of disassembly introduces certain risks. Understanding these risks and preparing accordingly will help ensure a successful procedure.

RISK AWARENESS

A primary concern involves electrical components. Although the solar panel converts sunlight into energy, stored battery power can present potential hazards if mishandled. Among the precautionary measures, turning off the solar light strip and draining any remaining power is advised. Disconnecting the batteries before beginning work ensures that there are no unintended shocks during manipulation.

Moreover, consider the environmental conditions where the device is being handled. Wet or moist environments may introduce hazards to electrical components, potentially leading to short circuits or damaging the components. It’s advisable to work in a dry, well-lit area to ensure comprehensive visibility during disassembly.

4. DISASSEMBLY STEPS

Having identified tools and safety considerations, the actual disassembly process can commence. Proceeding methodically through each step will facilitate a smoother experience.

STEP ONE: REMOVING FIXINGS

Start by inspecting the solar light strip for any visible screws or fasteners. Employing the previously selected screwdriver, carefully remove these fixings, taking care to set them aside for reassembly later. If the device features clips rather than screws, employ a non-conductive pry tool to gently disengage the housing. Always ensure that pressure is applied evenly to avoid breaking the housing.

STEP TWO: SEPARATING HOUSING

Once screws or clips are removed, gently pull the housing apart to reveal the internal components. Handle this step with care; applying excessive force can damage not only the housing but also the integral electronic parts hidden inside.

When separating the housing, it might be beneficial to have a secondary person on hand to stabilize the device, preventing it from shifting position or falling while work is being performed. Pay attention to how pieces are oriented, as this aids in an effortless reassembly process later.

STEP THREE: DISCONNECTING ELECTRONIC ELEMENTS

With the housing open, the next step involves safely disconnecting the solar panel and battery connections. Look for plug connectors, which typically allow for straightforward disconnection without the need for tools. Always remember to keep track of these connections, perhaps labeling them or taking photographs for clarity.

In some instances, wires may be soldered directly to the circuit board. In such cases, using a soldering iron may be necessary. If unfamiliar with soldering techniques, it’s advisable to seek assistance from someone experienced, as mistakes can lead to irreparable damage.

5. EVALUATING INTERNAL COMPONENTS

With separations completed, the examination of the internal components is crucial. Assessing each element allows users to identify any faults, plan repairs, or even upgrade parts if desired.

LED STRIPS

LEDs are the core of the lighting system, and careful examination can reveal performance issues or burnt-out bulbs. Should any bulbs be malfunctioning, options include replacing individual LED units or upgrading the entire strip for improved brightness. As technology evolves, better-quality LEDs give enhanced energy efficiency and illumination.

Additionally, consider how dust or grime build-up might affect LED performance; regularly cleaning these strips ensures longevity. Using a soft brush or cloth may solve minor issues, while replacements become necessary for more significant problems.

BATTERY SYSTEM

The battery’s condition is another essential component to evaluate. Most solar lights utilize rechargeable lithium-ion batteries; as such, knowing how to spot performance degradation aids in determining whether a replacement is necessary. Observing charge cycles and overall longevity affords insights into optimal battery health.

Often, battery replacement proves more efficient than trying to salvage existing units, which may have reached their effective lifespan. It is essential to choose batteries that match the specifications of the old ones, ensuring compatibility and effectiveness in enhancing performance.

6. REASSEMBLY PROCESS

Once tasks are complete, a return to assembly is warranted. Properly reconnecting components is pivotal for functionality upon completion.

RECONNECTING COMPONENTS

Begin by reversing the disassembly steps. Holiday attention to ensuring that all connections are securely fastened, especially regarding solar panels and batteries. Employ photographs taken during disassembly as a guide to ensure accurate assembly.

Check that screws are tightened evenly to maintain the housing’s integrity and prevent moisture intrusion, which could lead to long-term damage. If any wires or connections were detached, ensure they are securely reattached to avoid short-circuits or disconnections during usage.

FINAL CHECKS

Before placing the solar light strip back in its original position, conducting final checks becomes crucial. Testing each component ensures that any repairs or replacements performed were successful. Observing the illumination output tests the effectiveness of the LED bulbs and confirms seamless power transfer from the solar panel to the batteries.

Consider observing the solar panel’s ability to charge under sunlight conditions. Leaving the unit exposed to sunlight for a few hours permits monitoring of its overall functionality and efficiency, ensuring all parts are working harmoniously.

7. MAINTENANCE TIPS

Functionality and longevity hinge upon maintenance. Understanding simple upkeep practices can lead to a more fulfilling experience with movable solar light strips.

ROUTINE CHECKS

Regular inspections of the solar light strip can assist in the early identification of issues before they escalate. Elements to check include the integrity of the solar panel, the condition of the housing, and the cleanliness of LED bulbs.

Removing debris and dust regularly ensures that light output remains at optimal levels. Regular monitoring also affords insights into how environmental factors affect performance. For instance, ensuring there are no obstructions such as overgrown vegetation can substantially influence light efficiency.

TIMELY REPLACEMENTS

Engaging in timely replacements of batteries and LED components can offer sustained performance. Investing in high-quality, compatible parts ensures that replacements do not lead to further complications.

Moreover, familiarizing oneself with warranty details enables one to seek repairs or replacements from manufacturers when necessary, negating potential losses related to buying additional units prematurely.

WHAT TO DO IF THE LIGHT STRIP DOESN’T WORK?

TROUBLESHOOTING STEPS

If the light strip fails to operate post-disassembly and reassembly, following systematic troubleshooting steps can identify root causes. First, analyze if the batteries have adequate charge; if they appear depleted, charging for an uninterrupted duration may resolve the issue.

Next, examine the solar panel. The panel must receive unobstructed sunlight to function effectively. If it has been covered by foliage or dirt, cleaning the panel can significantly enhance performance. Investigate any wiring connections and solder points to ensure everything is securely fastened.

SEEKING PROFESSIONAL HELP

If all troubleshooting efforts do not yield results, it may be time to consult with a professional electrician or an expert in solar technology. They can provide insights that may not be immediately evident and potentially diagnose issues that require advanced tools or expertise.

IS DISASSEMBLING A MOVABLE SOLAR LIGHT STRIP SAFE?

SAFETY GUIDELINES

Disassembling a movable solar light strip is generally safe if proper precautions are taken beforehand. Wearing safety goggles and ensuring that the unit is unpowered can eliminate risks of injury from electrical shocks or flying debris while working.

Moreover, utilizing non-conductive tools minimizes potential hazards during the procedure. Ensuring the environment is dry and well-lit serves to further enhance safety, reducing the likelihood of accidents occurring during disassembly.

IMPORTANCE OF CAUTION

Moreover, it is crucial to handle internal components gently, as breaking small bits such as LED units or circuit boards can lead to costly repairs or replacements. Proceeding with caution and patience will ensure a secure and effective disassembly process.

CAN I REPLACE COMPONENTS MYSELF?

REPLACEMENTS AND SKILLS

Yes, many users can confidently replace components independently. However, having some basic knowledge about electronics and how various components function together aids in the process. Familiarity with soldering techniques and comfort working with small electronic parts greatly enhances successful replacements.

Moreover, consulting user manuals or online resources can offer guidance and detailed instructions specific to the light strip in question.

SEEKING EXPERTISE

If an individual is unsure about their ability to make effective replacements without risk to the device, consulting a certified technician remains a wise choice. Seeking expert assistance guarantees safety and effectiveness in preserving the light strip’s lifespan.

Utilizing a systematic approach for disassembling a movable solar light strip not only facilitates the maintenance and repair process but also ensures a deeper appreciation for the device’s functions. Emphasizing the importance of using appropriate tools, maintaining safety, and handling components with care ultimately leads to a rewarding experience. Adequate knowledge of how to disassemble, diagnose, and reassemble these strips cultivates user expertise and confidence in handling solar lighting technologies. Routine inspections and maintenance practices fortify longevity and functionality, promoting the continued usability of these utilities in diverse settings. This expertise makes it easier to troubleshoot, repair, or enhance movable solar light strips with minimal disruption and maximum effectiveness.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-movable-solar-light-strip/