1. Disassembling a mini solar street light requires specific steps to ensure proper separation of components, a safe environment, and a proactive approach to address any obstacles. 2. Gathering appropriate tools is crucial for efficiency, as inadequate equipment may impede the process. 3. Identifying the components, including the solar panel, battery, LED fixture, and pole, leads to a methodical disassembly. 4. Understanding the manufacturer’s instructions is essential, as variations exist among different models and brands. Detailed adherence to these steps minimizes the risk of damage and enables successful reassembly if necessary.

1. UNDERSTANDING THE COMPONENTS OF A MINI SOLAR STREET LIGHT

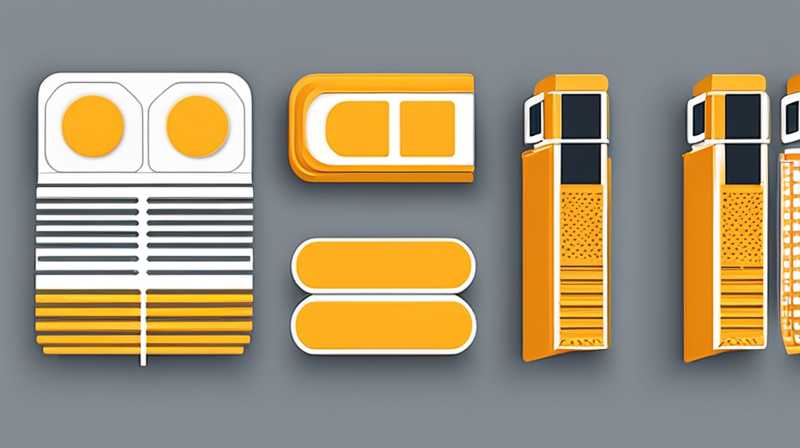

The mini solar street light typically consists of several crucial components, each serving a specific function. The main elements include the solar panel, the rechargeable battery, the LED light source, and the mounting pole. Each of these pieces works in harmony to provide an energy-efficient lighting solution. The solar panel captures sunlight and converts it into electrical energy, which is stored in the battery for nighttime use. The LED fixture emits light, while the pole supports the entire structure, allowing it to be mounted at an appropriate height.

It is important to recognize that the layout and assembly of mini solar street lights can vary depending on the specific manufacturer and model. Familiarizing oneself with the user manual provides valuable information regarding the arrangement of components, potential wiring configurations, and manufacturer-specific safety precautions. Evaluating the design of the specific model being disassembled ensures a smoother disassembly process, limiting surprises that could arise from unforeseen configurations.

2. PREPARING FOR DISASSEMBLY

Before initiating the disassembly process, one must gather all necessary tools and materials. Essential tools may include a screwdriver set, pliers, gloves, and safety glasses. Having the right tools on hand facilitates the process, ensuring that the components can be safely and efficiently detached without incurring harm. A clean and spacious workspace is also imperative, as it allows for the organized arrangement of parts and reduces the risk of misplacing or damaging components.

Another important preparatory step involves ensuring the solar light is not operational during disassembly. This typically means removing the device from direct sunlight and ensuring the light is turned off. Additionally, any attached wiring should be carefully assessed to confirm it doesn’t present any hazards. Taking time to prepare adequately can save significant frustration during the disassembly process and safeguard against inadvertent errors or accidents.

3. DISASSEMBLING THE SOLAR PANEL

The solar panel is often the first component to be disassembled due to its location at the top of the light fixture. Typically secured with screws or clips, careful handling is essential to avoid damaging the panel. The connection between the solar panel and the LED fixture should be examined for wires or connectors that may need to be detached before the panel can be completely removed.

When approaching the solar panel, ensure the workspace is free of debris to prevent scratches or breaks while handling the component. Support the panel adequately to avoid bending or damaging it during removal. If applicable, refer to the manual for guidance on disengaging any locking mechanisms or brackets that may secure the panel in place. Upon successfully detaching the solar panel, this component can be placed aside for further inspection or cleaning, if necessary.

4. REMOVING THE BATTERY

Following the disassembly of the solar panel, the next focus should be the rechargeable battery. Typically housed within the light fixture, accessing the battery may require additional detachment of surrounding covers or panels. Batteries can vary in configuration, meaning they may require specific techniques for safe removal. Avoid forcing any components as this can damage circuitry or connectors in the unit.

When extracting the battery, wear gloves to avoid potential hazards associated with lithium-ion batteries. Additionally, ensure that you are familiar with the battery’s specifications and type, as different batteries may have unique features or attachment methods. Once disconnected, the battery should be stored securely away from heat sources and in a dry location to mitigate the risk of leaks or other issues.

5. DETACHING THE LED LIGHT FIXTURE

After the battery has been removed, attention should shift to the LED light fixture. Most LED fixtures are secured via screws or clips, and care must be taken to ensure that the fixture is adequately supported before disconnection. LED components can be delicate, and applying excessive force can lead to damage.

Once the screws are undone, gently lift the LED fixture out of the housing unit. Be careful of any attached wires, ensuring they do not get snagged or damaged in the process. If any significant resistance is encountered, reassess the fixture for any additional fasteners that may have been overlooked. Proper care should be taken to store this component separately to prevent physical damage.

6. REMOVING THE MOUNTING POLE

The last significant component to disassemble is the mounting pole. Typically bolted into place either at the base or midsection, the removal of this pole requires attention to the securing methods used. Bolts and anchors should be removed methodically, ensuring that the pole is correctly supported while being disengaged.

Depending on the model, some poles may have adjustable height capabilities, and special attention should be paid to any mechanisms that can lead to changes in length. Once the pole is completely detached, it can be set aside for potential cleaning or maintenance. Understanding both the structure and materials used in constructing the pole is essential for maintaining the longevity of the component.

7. TROUBLESHOOTING COMMON ISSUES

Even when following all outlined procedures, various unforeseen issues can arise during disassembly. Common problems may include worn screws or damaged connectors, leading to complications throughout the process. Therefore, troubleshooting is an essential skill set when working on mechanical disassembly.

When faced with stubborn screws, employing penetrating oil can aid in loosening rusted or corroded fasteners. Utilizing tools such as pliers or screw extractors may also become necessary in problematic situations. Whenever possible, it is crucial to document any issues encountered in order to avoid recurring mistakes in the future.

8. REASSEMBLY CONSIDERATIONS

Upon successful disassembly, attention should be turned toward reassembly, whether for maintenance, part replacement, or upgrades. Ensuring that all components are cleaned and inspected is paramount, as dust or residue can impede performance. Following the reverse order of disassembly can streamline the process; however, it is crucial to reference the user manual whenever ambiguity arises.

In reassembly, careful calibration of electrical connections is also necessary to maintain efficient performance. Taking the time to ensure each connection is secure and functioning properly will enhance the longevity of the assembled unit. Thorough and meticulous reassembly will not only restore your mini solar street light but also improve its overall functionality.

9. MAINTAINING YOUR MINI SOLAR STREET LIGHT

Regular maintenance after disassembly and reassembly ensures proper functionality over time. Routine inspections, cleaning of solar panels, and battery management can significantly enhance performance. Recognizing the lifespan of components and addressing any deterioration can significantly extend the life of the unit.

It’s advisable to remain vigilant about outdoor conditions, especially in winter or extreme climates, as humidity and heavy debris can negatively impact functionality. Taking a proactive approach to maintenance will ensure consistent operation and prevent premature failure of critical components. This vigilance can also lead to cost-saving benefits, as minor repairs are significantly less expensive than full replacements.

QUESTIONS AND ANSWERS

1. HOW OFTEN SHOULD I DISASSEMBLE MY MINI SOLAR STREET LIGHT FOR MAINTENANCE?

It is advisable to conduct an inspection of your mini solar street light at least twice a year. This preventative measure comprises examining the solar panel for dirt or debris, checking battery health, and assessing the LED light for any flickering or dimming issues. Increased frequency may be required if the light is positioned in an area with heavy foliage or is subject to severe weather conditions. Engaging in seasonal maintenance not only prolongs the life of the components but also ensures maximum efficiency.

The disassembly process during maintenance should ideally focus on cleaning and checking connections rather than complete removal of components. While full disassembly may not be necessary each time, familiarity with the process will allow for quick access to parts when replacements or repairs are needed. Being proactive about maintenance minimizes the risk of unexpected failures and enhances performance longevity.

2. WHAT TOOLS ARE REQUIRED TO DISASSEMBLE A MINI SOLAR STREET LIGHT?

The tools needed to dismantle a mini solar street light largely depend on the specific model and manufacturer, but typically include essential items such as a screwdriver set, pliers, and gloves. A variety of screwdrivers (Phillips and flathead) is crucial to handle various screw types commonly encountered in these fixtures. Additionally, having a pair of pliers or wire cutters can be advantageous for disconnecting any stubborn or tightly secured components.

In some cases, innovative designs may require specialty tools. Therefore, it is recommended to consult the manufacturer’s guidelines for any specific tools or equipment that might be necessary for safe disassembly. Safety gear such as gloves and protective eyewear can safeguard against injury while handling sharp pieces or electrical elements.

3. CAN I RESUSE PARTS FROM AN OLD SOLAR STREET LIGHT?

Repurposing parts from an old solar street light can be an excellent way to save costs while maintaining functionality. Components such as solar panels and LED fixtures are designed for longevity, making them suitable for reuse if they remain in good working condition. However, inspecting each element thoroughly for wear and tear ensures reliability in continued use.

Reusing parts not only minimizes waste but can also provide a cost-effective solution for repairs or upgrades. Before taking on this task, it is essential to understand the compatibility of reused components with existing mechanisms to avoid future issues. Recyclability is instrumental to modern sustainability practices, and maximizing the lifespan of each component contributes positively to both environmental and economic factors.

Maintaining and disassembling a mini solar street light reflects a meaningful investment in sustainable energy methods. Through careful consideration of each step, tools, and ongoing maintenance, anyone can navigate this process successfully. Undoubtedly, undertaking such tasks not only boosts user understanding of solar technology but also enhances responsible energy consumption practices. Over time, the knowledge acquired complements both personal satisfaction and contributes to broader environmental initiatives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-the-mini-solar-street-light/