Disassembling solar pipe fittings involves a systematic approach that requires attention to detail and proper tools. 1. Preparation is crucial; gather all necessary tools and materials such as wrenches, pliers, and safety equipment. 2. Identify the type of fittings used in the solar piping system, as this can vary significantly based on the installation. 3. Remove any insulation or coverings that may obstruct access to the fittings. 4. Finally, follow the manufacturer’s guidelines precisely to avoid damaging components or compromising the system’s integrity. For instance, fittings may be glued or soldered in certain systems, necessitating a different disassembly strategy than mechanical fittings that merely screw together.

1. UNDERSTANDING SOLAR PIPE FITTINGS

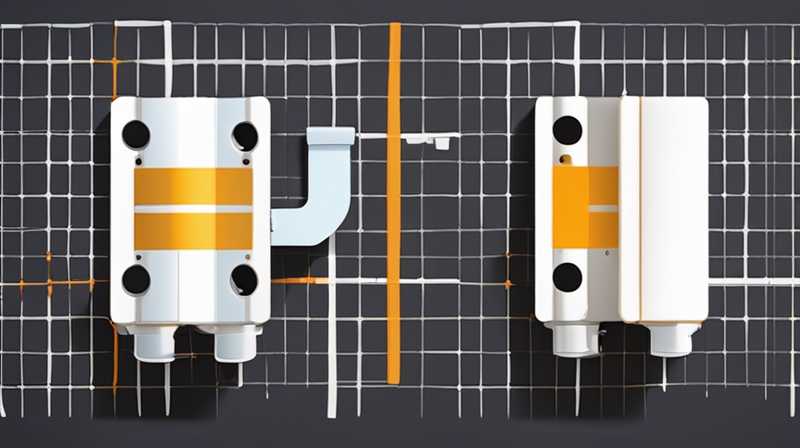

When contemplating the disassembly of solar pipe fittings, one must first grasp the fundamental construction and purpose of these components. Solar pipe fittings serve as crucial connections within a solar thermal system, facilitating the flow of heat transfer fluids. These fittings come in numerous styles, including threaded, compression, soldered, and push-fit, each designed to create a secure seal between pipes and components.

Understanding the different types of materials used is essential. Most fittings are made from metals such as copper, stainless steel, or thermoplastics. Metallic fittings tend to be more durable and suitable for high-pressure systems, while plastic fittings are lighter and often more resistant to corrosion. Comprehending the specific materials involved is vital, as it influences the approach to disassembly. For instance, a copper fitting may require a different method compared to a PVC one, particularly regarding heat application or the need for specific tools.

2. GATHERING THE NECESSARY TOOLS AND MATERIALS

To embark on the disassembly task effectively, one must equip themselves with the appropriate tools and materials. The primary tools typically include wrenches, pliers, a heat source for soldered fittings, and safety goggles to protect the eyes. Having high-quality tools not only fosters efficiency but also minimizes the chances of causing damage to the fittings or surrounding pipes.

Moreover, some procedures may necessitate additional materials such as thread sealant or replacement O-rings. Identifying whether any replacement parts will be needed post-disassembly can save time and alleviate frustration later. For instance, if the fittings are especially old or corroded, it’s prudent to plan for possible replacements to ensure the system operates optimally after reassembly. Therefore, assessing the condition of existing fittings and having a complete toolkit ready enhances the disassembly process significantly.

3. SAFETY MEASURES AND PREPARATION

Safety should always be a foremost consideration when working with plumbing systems, especially those associated with solar energy. Before starting the disassembly process, one must de-pressurize the system completely and ensure no fluids remain in the pipes. A significant risk arises if pressurized fluid escapes during disassembly, potentially resulting in injuries or damage.

Utilizing personal protective equipment is equally important. Safety goggles protect your eyes from debris, while gloves can shield hands from sharp edges and hazardous materials. Additionally, wearing long sleeves and closed-toe shoes can further mitigate the risk of injury. Preparing the workspace by ensuring it is clean and well-lit contributes to a safer environment as well. By taking these measures, one not only safeguards themselves but also promotes a smoother procedure without complications arising from environmental factors.

4. REMOVING INSULATION OR COVERS

Many solar pipe systems are insulated to enhance energy efficiency and minimize heat loss. Before attempting to disassemble any fittings, it is essential to remove insulation or coverings without damaging the underlying pipes. This task requires careful execution to maintain the integrity of the pipes and fittings, particularly if re-insulation will occur afterward.

There are various types of insulation, from foam to fiberglass wraps. Using a utility knife or scissors, cut the insulation carefully, taking care not to penetrate too deeply. Once the insulation has been removed, inspect the fittings for any additional coverings such as tape or protective casings that may also need to be eliminated for easier access. By ensuring all barriers are cleared, one lays the groundwork for a more efficient disassembly process, allowing for unobstructed access to the fittings.

5. INSPECTING AND IDENTIFYING THE FITTINGS

Once the preparatory steps are completed, the next phase involves inspecting the fittings to determine their specific type and condition. Identifying whether a fitting is threaded, soldered, other types enables an appropriate disassembly method to be selected. Each type presents unique challenges and requires a tailored approach for removal and potential reinstallation.

For example, threaded fittings can typically be unscrewed by hand or with a wrench. In contrast, soldered fittings require heat application to melt the solder, facilitating the disassembly process. Similarly, push-fit connections often only need a simple compression or release of the fitting lock. Understanding the makeup of the fittings will not only simplify the disassembly task but also aid in planning for replacements or reassembly, ensuring that the fitting’s functionality is preserved in the solar system.

6. DISASSEMBLING THREADED FITTINGS

When dealing with threaded fittings, the process tends to be straightforward. Begin by turning each fitting counter-clockwise using an appropriately sized wrench. Adequate grip is essential; for particularly stubborn connections, a penetrating oil may be applied beforehand to loosen any rust or corrosion that may be present.

After unscrewing the fittings, inspect the threads for wear or damage, allowing for informed decisions regarding future replacements. Should new fittings be necessary, ensuring they are of compatible size and material promotes system reliability. One must also clean any remnants of pipe sealant or tape from the threads of both the fitting and pipe to ensure a secure connection upon reassembly, thereby influencing the efficacy of the overall solar thermal system.

7. HANDLING SOLDERED FITTINGS

Soldered fittings require a more nuanced approach, as they are bonded through heated metal. Initiate the disassembly process by applying a heat source to the fitting area, focusing on melting the solder. Care must be taken to apply heat evenly to avoid damaging surrounding components or pipes.

Once the solder reaches its melting point, gently pull the fitting away while ensuring the molten solder does not re-solidify. After successful removal, allow both the pipes and fittings to cool down; at this stage, one may inspect the condition of the fitting for any signs of wear. If any solder residue is present on the pipes, it should be cleaned off to allow for a smooth connection during reassembly. This careful consideration in method execution amplifies the lifespan and efficiency of the solar system.

8. DISASSEMBLING COMPRESSION FITTINGS

Compression fittings operate through mechanical force, making them relatively easy to disassemble compared to other types. To begin, loosen the compression nut with a wrench, ensuring not to apply excessive force that may damage the fitting. It is important to proceed slowly and check for resistance, indicating potential cross-threading or damage to the components.

After the nut is sufficiently loosened, the fitting can be unscrewed from the pipe without requiring heat or extensive force. Once removed, inspect the sealing rings or olives for wear; if found defective, replacements should be on hand to ensure a tight seal upon reassembly. Proper handling of compression fittings contributes to the longevity of the components and minimizes leakage in the solar piping system.

9. DISASSEMBLING PUSH-FIT FITTINGS

Push-fit fittings rely on an internal mechanism that grips the pipe and enables quick disassembly without the need for tools. To separate these fittings, simply pull the pipe away from the fitting while applying a slight pinch to the release tab if one is present. Care must be taken to avoid excessive force, which may damage the fitting or pipe.

After successful removal, inspect the pipe and fitting for wear or damage. If a fitting is to be reused, it is vital to check the integrity of its internal components to prevent leaks. Push-fit connections are preferred for their ease of installation and removal, making them an excellent choice for future upgrades or adjustments within a solar thermal system.

10. INSPECTING AND REPLACING COMPONENTS

After disassembly, it is essential to conduct a thorough inspection of all components that have been removed. Look for signs of wear, corrosion, or damage that may prevent optimal functioning of the solar system upon reassembly. Identifying defective parts early on prevents costly repairs in the future and ensures that the system operates efficiently.

If any components must be replaced, ensure that the new parts align with the specifications of the existing system. This includes verifying compatibility with the material of the pipes and fittings as well as the dimensions involved. Equipping oneself with appropriate replacement parts streamlines the reassembly process and promotes the longevity and effectiveness of the solar piping system in general.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NEEDED FOR DISASSEMBLING SOLAR PIPE FITTINGS?

When undertaking the task of disassembling solar pipe fittings, a variety of tools and materials are essential to ensure a smooth and efficient process. Tools typically required include wrenches of varying sizes, pliers, a utility knife for any insulation removal, and, in the case of soldered fittings, a torch for heating the connections. Safety equipment such as gloves, safety goggles, and a well-lit workspace is also crucial. A thorough preparation stage where all necessary equipment is gathered can save time and reduce frustration during disassembly. Additionally, having a threading sealant or O-rings on hand for replacement can further streamline the reassembly process, ensuring that all components function effectively after the fittings have been disconnected.

HOW TO IDENTIFY THE TYPE OF SOLAR PIPE FITTINGS?

Identifying the type of solar pipe fittings is vital for determining the appropriate method of disassembly. Fittings come in various forms including threaded, soldered, compression, and push-fit. A visual inspection is the simplest way to assess what type is present; threaded fittings exhibit visible threads, whereas soldered ones have a smooth appearance where the solder has sealed the join. Compression fittings will typically present a nut at the junction, and push-fit fittings appear as slightly larger connections that don’t require threading. Further research into the specific solar installation may provide additional insights into the types of fittings used, enabling more informed handling during disassembly.

ARE THERE ANY SAFETY RISKS WHILE DISASSEMBLING SOLAR PIPE FITTINGS?

Engaging in the disassembly of solar pipe fittings does entail certain safety risks, primarily associated with pressurized fluids and heating components. Before starting, it is imperative to completely depressurize the system to prevent the sudden release of fluids that could cause injury. Furthermore, when dealing with soldered fittings, the application of heat introduces the risk of burns. Protective gear such as gloves and goggles should be mandatory to mitigate these risks. A well-prepared workspace also aids in ensuring safety; keeping it organized reduces the chances of accidents and promotes an efficient disassembly process. Therefore, prioritizing safety is essential to prevent injuries and ensure a successful operation.

In summary, disassembling solar pipe fittings is not merely a mechanical task but rather involves a series of carefully considered steps that ensure the integrity and functionality of the solar thermal system. Each stage, from understanding fitting types to gathering tools, includes meticulous measures aimed at safety and effectiveness. Rarely is a single method applicable as various fitting types demand distinct techniques. When encountering threaded fittings, the process is straightforward, whereas soldered ones call for heat application and added caution. Furthermore, recognizing the nuances involves comprehensively inspecting and replacing components when necessary. Throughout, prioritizing personal safety and proper tool usage enhances the overall operation, ensuring longevity and optimizing performance within the solar system. Hence, approaching the task methodically is critical, as it ultimately influences the efficiency and reliability of the solar energy system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-solar-pipe-fittings/