To effectively disassemble solar hose parts, precision and a systematic approach are paramount. 1. Wear appropriate safety gear to protect your eyes and hands, ensuring a secure workspace. 2. Identify and document each component’s arrangement to facilitate proper reassembly. 3. Utilize the correct tools, such as pliers and a wrench, to detach fittings carefully. 4. Place all parts in separate, labeled containers, preventing confusion during reassembly. In detail, the methodical disassembly of each part includes understanding the structural design and avoiding damage to any components. By adopting these practices, the overall task can be executed seamlessly and efficiently.

1. PREPARATION FOR DISASSEMBLY

Preparation plays a critical role in the success of disassembling solar hose parts. The initial phase necessitates gathering essential tools and protective gear to ensure both safety and efficiency. Safety goggles and gloves are a must, as they safeguard against potential injuries from sharp edges or pressurized components. In addition to safety equipment, appropriate tools, including adjustable wrenches, Vise-Grips, and screwdrivers, should be assembled. Choosing the right tool that fits the fittings can significantly ease the process.

Additionally, the workspace must be organized and well-illuminated. Utilizing a clean, flat surface can minimize accidents and enhance focus. Anxiety during disassembly may arise if multiple fittings or components are cluttered. It would be prudent to strategically lay out towels or open boxes to prevent small components from rolling away. Prioritizing a methodical approach not only streamlines the disassembly process but also prepares for an organized reassembly later on.

2. IDENTIFYING COMPONENTS

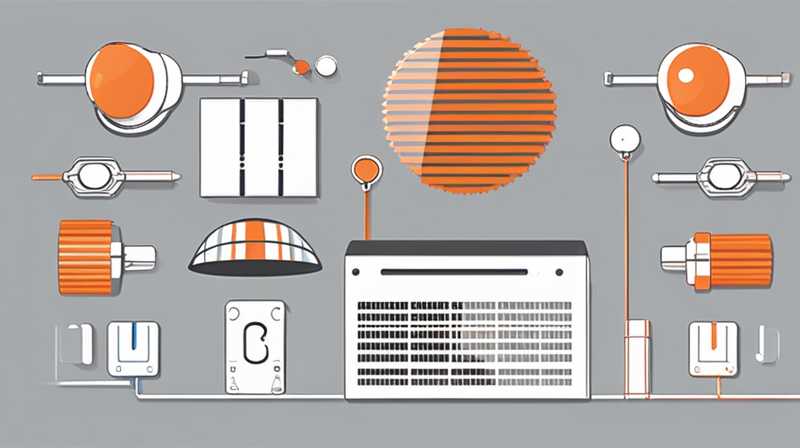

Understanding the various elements of a solar hose system is crucial for effective disassembly. The solar hose system typically consists of several components, including connectors, valves, and the hose itself. Familiarity with each section aids in ascertaining which elements require disassembly. It is advantageous to consult the manufacturer’s manual if available, as it provides specific diagrams and descriptions of various parts, facilitating informed decisions during the disassembly process.

Moreover, noting the function of each component assists in determining the appropriate disassembly sequence. For example, disconnecting a valve may be necessary before removing the hose to prevent residual fluid from leaking. Ensuring clarity on the operational aspects of each part will lead to a more streamlined process, ultimately augmenting the efficiency of the operation.

3. DISCONNECTING THE HOSE

The disconnection of the hose from other elements is a crucial step in the disassembly of solar hose parts. Start by identifying how the hose is connected to the system, as connections can vary widely based on design and manufacturer. Some hoses may simply have a clamp holding them in place, while others might feature twist-loc connections or specialized quick-connect fittings. Understanding the specific connection type is vital to avoid damaging both the hose and the connecting components.

Once the connection type is identified, the next step involves the careful removal of the hose. If clamps are present, utilize a suitable tool to loosen and remove them. Ensure a controlled approach to prevent any sudden releases or damages to adjacent parts. Following the removal of the hose, inspect both the hose and the connectors for wear, damage, or buildup, which could indicate underlying issues. Documenting these findings can be beneficial for future repairs or replacements.

4. REMOVING VALVES AND CONNECTORS

The elimination of valves and connectors after disconnecting the hose is pivotal. Whether the valve serves a critical or incidental purpose, having a comprehensive understanding of its function will dictate the removal procedure. Like hoses, valves may have different connection types, such as threaded ends that require twisting or integrated clips that need to be unpinned for removal. Recognizing this variation enables a more precise and straightforward disassembly.

During valve removal, it is essential to collect any seals or O-rings that may detach in the process. These components are often critical for maintaining system integrity. Inspecting these parts for wear can inform future maintenance efforts. Simultaneously, ensure that all parts remain organized by placing them in labeled containers. This meticulous documentation ensures easy reassembly post-maintenance or repair.

5. HANDLING SMALL COMPONENTS

Handling small components requires particular attention to detail. Items such as nuts, screws, or washers can often be overlooked during disassembly but are crucial for the fastening of larger parts. The loss of even a single component can hinder reassembly or threaten the functionality of the solar hose system. Consider utilizing magnetic trays or small containers to securely collect these components throughout the disassembly process.

Moreover, each small component should be identified and labeled, ensuring that reassembly is as efficient as the disassembly was meticulous. Keeping a detailed inventory of parts may prove especially useful when several hoses or devices are being worked on simultaneously. Properly accounting for these elements will ensure a smoother workflow and prevent any potential mishaps further down the line.

6. DOCUMENTING THE PROCESS

Meticulously documenting each step of the disassembly process is instrumental for future reference. Creating a clear, step-by-step outline of the disassembly can be invaluable for future projects or maintenance. This documentation may include photographs, written notes, and annotated diagrams, which offer visual cues when reassembling components. Recording how each part fits with others can significantly reduce the risk of mistakes.

Additionally, thorough documentation can aid in identifying potential issues or maintenance needs within the system. For instance, noting any signs of wear or malfunctioning parts allows for proactive replacements before an issue escalates. This foresight saves time and reduces costs, enhancing the overall longevity of the solar heater system.

7. TIPS FOR REASSEMBLY

Reassembly should proceed methodically, following the inverse order of disassembly. Refer to the documentation created during the disassembly to ensure each component has its rightful place. Check each part for wear or damage before reattaching it, as prevention of future issues is more efficient than reaction-based solutions.

Furthermore, utilize new seals or O-rings where necessary. Old or compromised seals may lead to future leaks or equipment failure. Take care to tighten fittings appropriately, ensuring they are snug without risking damage to threads or components. Following procedures, aligning parts properly, and ensuring cleanliness can promote optimal function upon completion of the reassembly process.

8. COMMON MISTAKES TO AVOID

Awareness of common mistakes can greatly improve the efficiency of disassembly and reassembly. Rushing through the disassembly process often leads to careless damage to parts. Ensuring each step is approached with focus and clarity mitigates these risks.

Another common mistake involves neglecting to properly secure small components during the disassembly. Precautionary measures should be taken to safeguard against the accidental loss of these vital pieces. Furthermore, failings to document the process entirely may lead to confusion during reassembly. Staying diligent and methodical can greatly enhance efficiency and lead to fewer complications.

9. APPRECIATING THE SYSTEM

An appreciation for the solar hose system and its components is essential. Understanding how each hose, valve, and connector contributes to the efficiency of the solar heating system instills a sense of purpose in the maintenance process. This foundational knowledge fosters respect for the engineering behind such systems, elevating the approach toward repairs and replacements.

Moreover, this deeper level of comprehension encourages proactive maintenance, enhancing the longevity of the solar heating system. Taking the time to learn and appreciate these components ultimately benefits both functionality and sustainability, as maintaining these systems supports energy-efficient solutions.

10. RESOURCES FOR FURTHER EDUCATION

Those looking to deepen their understanding of solar hose systems and their components can benefit from various resources. Online forums and community boards can provide insights from other experienced users who’ve navigated similar processes. Additionally, manufacturer manuals often contain rich, detailed instructions and troubleshooting tips for specific products.

Specialized training sessions or workshops can improve skill sets related to disassembly and maintenance. Engaging in educational opportunities fosters a deeper understanding of the technology and maximizes the effectiveness of one’s own systems.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NEEDED FOR DISASSEMBLING SOLAR HOSE PARTS?

When preparing for the disassembly of solar hose parts, assembling an appropriate toolkit is crucial. Typically, essential tools include adjustable wrenches, pliers, screwdrivers, and safety goggles. The adjustable wrenches are particularly useful for loosening and tightening fittings at different angles without needing multiple sockets. Pliers can help grip smaller components while offering leverage for stubborn parts.

Safety goggles are non-negotiable as they protect the eyes from debris or unexpected fluid sprays that can occur when disconnecting hoses or fittings. In addition to these primary tools, a clean work surface, magnetic trays for collecting small parts, and labeled containers can vastly enhance the efficiency of the work process.

IS IT NECESSARY TO REPLACE SEALS AND O-RINGS DURING REASSEMBLY?

Yes, while reassembling solar hose components, addressing seals and O-rings is essential. Over time, these components can wear out or become degraded due to exposure to sunlight or constant pressure changes. Using old seals may lead to leaks or improper functioning of the system.

Incorporating new seals and O-rings during reassembly can enhance the unit’s efficiency and longevity. This preventive maintenance ensures that all connections remain watertight and assists in maintaining optimal operational levels in solar heating systems, thereby saving on potential repairs in the future.

ARE THERE SPECIFIC SAFETY PRECAUTIONS TO KEEP IN MIND?

Absolutely, there are significant safety precautions to consider while disassembling solar hose parts. Wearing safety goggles and gloves is non-negotiable to protect oneself from possible injuries. Furthermore, ensuring that the system is depressurized and drained before starting disassembly is vital.

Taking time to assess the workspace for potential hazards can minimize the risk of accidents. Additionally, being aware of how components are interconnected will help prevent unexpected releases of fluids or pressure. Overall, maintaining a diligent and cautious approach fosters a safer working environment.

Each aspect of the disassembly process is critical for ensuring a functional and efficient solar heating system. As each step is carried out with care, maintaining an organized workspace and a comprehensive understanding of parts leads to a successful operation. Documentation plays a significant role in ensuring that future endeavors run smoothly. Emphasizing safety and employing a systematic approach contributes to the long-term efficacy of solar equipment, ensuring a sustainable and reliable energy solution. Having a firm grasp on the importance of proper maintenance not only extends the life of the solar hose system but also promotes a functional environment conducive to learning and improvement.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-solar-hose-parts/