To properly disassemble old solar tubes, one must follow a meticulous process that ensures safety and effectiveness. 1. Ensure Safety Measures, 2. Gather Necessary Tools, 3. Examine the Installation, 4. Disconnect any Electrical Components, 5. Remove the Tubes, 6. Dispose of Properly. One critical aspect involves ensuring safety measures are strictly adhered to, including wearing appropriate protective gear and being aware of potential hazards.

1. ENSURE SAFETY MEASURES

Undertaking the disassembly of solar tubes demands an emphasis on safety practices to avoid potential hazards. Ensuring one is equipped with personal protective equipment (PPE) is paramount; this may include safety goggles, gloves, and a hard hat, especially if there’s a risk of falling debris. Additionally, evaluating the workspace for insecure surfaces or unstable ladders can prevent accidents during the dismantling process. Being aware of the solar tubes’ materials can also play a crucial role in determining appropriate handling and disposal procedures.

Furthermore, working in a well-ventilated area is essential. When disassembling solar tubes, there may be inherent risks involving chemicals or components that could emit harmful gases or particulates. By maximizing ventilation, individuals can mitigate the risk of inhaling anything hazardous, thereby prioritizing one’s health during the entire operation.

2. GATHER NECESSARY TOOLS

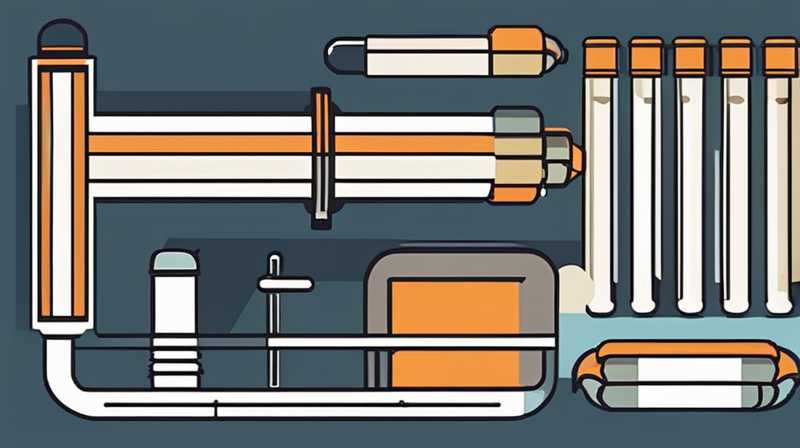

Collecting the correct tools simplifies the disassembly process and enhances efficiency. Some of the essential tools required include socket wrenches, screwdrivers of various types, pliers, and a utility knife. By organizing tools beforehand, one minimizes interruptions during the disassembly, allowing for a smoother workflow. In situations where the solar tube system has been connected using specific fasteners like bolts or rivets, having the correct sizes readily available can save considerable time and effort.

Additionally, utilizing a toolbox can keep the workspace neat and offer quick access to tools as needed. Alongside standard tools, having safety gear such as a first-aid kit nearby can prove invaluable in case of unforeseen incidents. This preparation ensures assistance and swift action against any minor injuries, thereby maintaining a safe working environment throughout the disassembly. Properly equipping oneself with tools and safety equipment lays a solid groundwork for a successful dismantling experience.

3. EXAMINE THE INSTALLATION

Before the actual dismantling begins, thoroughly inspecting the solar tube setup is crucial. This involves understanding how the tubes are integrated into the wider solar system. Documentation such as installation manuals or schematics can be invaluable for visualizing the connections and components that comprise the installation. Taking notes about the configuration will assist in ensuring all connections are recognized and appropriately handled during disassembly.

Moreover, being familiar with the environmental conditions around the installation can also inform safety protocols. For instance, checking if there are electric supply lines in proximity is vital to prevent electrocution during tube disconnection. In scenarios where weather conditions may affect the disassembly, such as rain or wind, it may be prudent to delay the operation. Taking the time to fully assess the installation context can significantly reduce hazards and ensure an organized and systematic approach when dismantling.

4. DISCONNECT ANY ELECTRICAL COMPONENTS

Many solar tube systems come equipped with electrical components, including sensors, controllers, or water heating elements. Identifying and disconnecting these components safely is a critical step in preventing electrical accidents. Before undertaking any disconnection, it is advisable to cut off power to the system, ensuring that all electrical feeds are disabled. This precaution greatly minimizes the risk of shock or short circuits.

After the power supply has been safely addressed, each component should be systematically detached. Start by removing any visible wires and connectors; taking pictures at each stage allows for easier reassembly should it be necessary later. It is also worthwhile to label each connection or create a small inventory to prevent confusion during reengineering or cleanup. Through careful disconnection processes, the integrity of both electrical components and the structure surrounding the solar tubes can be preserved, facilitating a cleaner and safer dismantling operation.

5. REMOVE THE TUBES

With electrical components disconnected and the tubes sufficiently examined, attention turns to the actual removal of the tubes. This process may vary based on the particular installation and mounting system used. For tubes that are rigidly fastened to a frame, using appropriate tools, like a socket wrench or screwdriver, to remove any support brackets is key. This stage requires ensuring that all screws or guards are completely detached before attempting to lift or slide the tubes away from their mounts.

When lifting the tubes, employing proper body mechanics will help avoid personal injury. By bending at the knees and maintaining a firm grip, it becomes easier to manage the weight and balance of the materials. If the tubes are especially lengthy or cumbersome, enlisting the assistance of another person can be advantageous. Once each tube has been successfully removed, placing them in a designated area for transport or storage prevents clutter and ensures safety while moving around the workspace.

6. DISPOSE OF PROPERLY

The proper disposal of old solar tubes is not only considerate but may also be a legal requirement in many regions. Before disposing of the tubes, research local regulations regarding hazardous waste and recycling initiatives, as some materials used in solar tubes may require special handling. It often falls on the responsibility of the individual disassembling the tubes to facilitate their correct disposition.

Recycling centers may accept components from solar tubes, including metals or glass, and many eco-friendly disposal programs exist. Contacting local waste management services can provide guidance regarding what materials are permissible. It’s also recommended to keep abreast of any environmental guidelines which may dictate disposal protocol. By ensuring the tubes are disposed of sustainably, one contributes positively to environmental conservation and demonstrates responsible stewardship of resources.

FAQs

HOW LONG DOES IT TAKE TO DISASSEMBLE OLD SOLAR TUBES?

The timeframe for disassembling old solar tubes can vary significantly based on several factors. Coordination among helpers, the complexity of the installation, and familiarity with the necessary tools all contribute to the duration. On average, the disassembly process can take anywhere from three to six hours.

Additionally, preparatory actions such as gathering tools and ensuring safety measures may extend this time further. Subsequently, if any unforeseen challenges arise, such as rusted or difficult-to-remove components, it may prolong the process. Establishing a structured approach and ensuring adequate assistance can expedite disassembling while minimizing frustration or hazards.

WHAT SHOULD I DO IF I ENCOUNTER RUSTED OR DAMAGED COMPONENTS?

Encountering rusted or damaged components during disassembly is not uncommon, and addressing these appropriately is crucial to ensure safety and prevent further complications. It is vital to assess the extent of the damage. In case of minor rust, applying a lubricant or rust remover can facilitate easier disassembly, allowing for smoother removal of affected components.

If components are severely rusted or damaged beyond repair, it may be necessary to replace them. In such cases, appropriate care should be taken to use protective gear when handling rusted parts, as they might have sharp edges. Furthermore, evaluating the project’s budget and timeline impacts decisions around replacing parts. Consulting a professional may also be advisable if the situation appears complex or dangerous.

CAN I REUSE OLD SOLAR TUBES IN A NEW INSTALLATION?

Reusing old solar tubes in new installations can be a cost-effective and environmentally friendly decision, though it requires careful consideration. Firstly, one must assess the structural integrity of the tubes, as any signs of damage or degradation may render them unsuitable for reuse.

Conducting a thorough inspection of each individual unit ensures their capability to perform effectively in a new setup. Additionally, compatibility with new systems must be examined, as some solar technologies have evolved significantly, potentially rendering older models incompatible. If the tubes pass inspections for both condition and compatibility, they can be reused, thus optimizing resources and contributing to sustainability initiatives within the renewable energy sector.

Engaging in the disassembly of old solar tubes necessitates careful planning and execution. Adhering to safety protocols, gathering appropriate tools, and considering environmental factors elevate the process’s effectiveness while minimizing hazards. Each aspect involved in this undertakings—such as inspecting installations, disconnecting electrical components, and ensuring proper disposal—demands diligent attention to detail. The complexity of disassembling solar tubes speaks to the broader challenges faced in dismantling renewable energy technologies efficiently and safely. By being equipped with appropriate knowledge and methodologies, it becomes feasible to successfully undertake such projects. These practices not only promote safety but also highlight the importance of sustainable waste management and resource reuse, making a positive contribution toward environmental preservation. Ultimately, undertaking these operations with authenticity can yield beneficial results for oneself and the wider community in pursuit of sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-old-solar-tubes/