To disassemble an IP67 solar light, follow these essential steps: 1. Disconnect power source carefully, 2. Remove screws or fasteners meticulously, 3. Detach the housing from the light unit, 4. Take out the solar panel, battery, and circuit board systematically. Understanding the importance of each phase ensures safety and prevents damage. Begin by ensuring the device is powered off, then use appropriate tools to access the interior components without causing harm.

1. UNDERSTANDING IP67 RATING

The designation IP67 signifies that a product is both dust-tight and can withstand immersion in water up to one meter for a duration of 30 minutes. This rating pertains particularly to devices like solar lights, which need to function effectively in varied environmental conditions. Recognizing the implications of such a rating is crucial for correct disassembly, as it typically involves sealed units designed for longevity and resilience.

The first aspect to contemplate is the design philosophy behind IP67-rated devices. Such products are engineered to endure adverse weather, which means that manufacturing involves robust materials impermeable to dust and water. Consequently, during disassembly, one must leverage caution as these robust seals can be delicate. Disassembling these units without compromising their integrity is a skill that requires patience and precision.

2. GATHERING THE NECESSARY TOOLS

Proper disassembly of an IP67 solar light hinges on utilizing the right tools. Having the correct equipment streamlines the process and minimizes the risk of damage to components. Among the necessary tools, one would typically require a small screwdriver set, which includes both Phillips and flathead variations, ensuring that all types of screws can be addressed. Moreover, a plastic pry tool or spudger is beneficial to detach the housing without scratching or harming the unit.

In addition to the tools mentioned, it may also be prudent to use safety goggles and gloves. While the necessary disassembly may appear routine, it is essential to protect oneself from potential sharp edges or fragments that could be dislodged in the process. Ensuring personal safety is as important as the successful completion of device disassembly.

3. DISCONNECTING THE POWER SOURCE

Before initiating any disassembly, ensure that any power supply to the solar light has been disconnected. This precaution is vital to safeguard against electrical shock and accidental activation of the light during the process. The procedures here may vary depending on whether the light is integrated into a larger system or operates independently.

To commence, locate the power switch on the device or simply ensure the solar panel is not exposed to sunlight. By covering the solar panel with an opaque material, one can effectively render the light inoperative, granting a higher degree of safety during disassembly. It is also advisable to examine the battery compartment if accessible, to safely remove any batteries if they exist.

4. REMOVING SCREWS AND FASTENERS

With the power source safely disconnected, the next step involves removing screws or fasteners that secure the solar light’s housing. This process requires a thorough understanding of the screw types present, as they can vary in shape and size. Using a magnetic organizer can be advantageous for keeping track of screws as they are removed.

Begin by identifying the locations of screws, which may be obscured by seals or covers. It is imperative to use the correct screwdriver size to avoid stripping the screws, which can render future disassembly difficult. Once all screws have been removed, gently lift the housing to see if it detaches easily or if additional fasteners are present. Understanding the assembly design can aid immensely here.

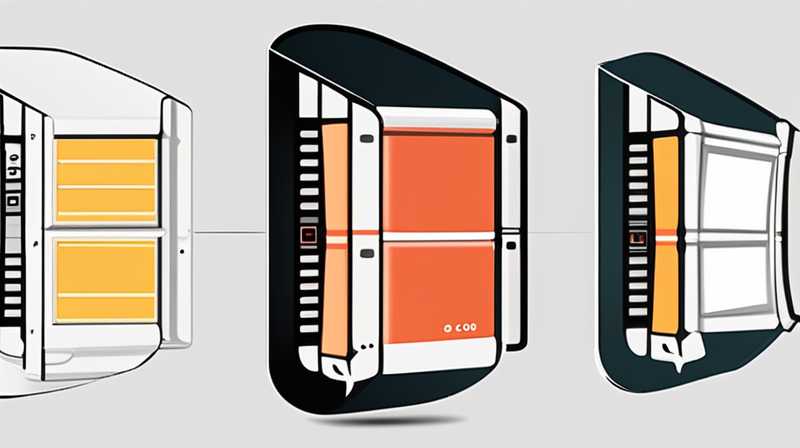

5. DETACHING THE HOUSING

After removing all screws and fasteners, the next step is to detach the housing from the light unit. This phase requires delicacy, as there may be a rubber gasket or seal intended to protect the internal components from moisture. Use a plastic pry tool to insert between the seams of the housing gently; this approach will minimize damage.

As the housing comes apart, it’s essential to monitor for additional wires or components that may remain attached. By keeping an eye on these connections, one can ensure that the disassembly process does not inadvertently sever important wires, which could compromise the rest of the light’s functionality.

6. REMOVING THE SOLAR PANEL

With the housing successfully removed, the next logical step is to detach the solar panel from the device. This can be a straightforward process, as it usually involves unscrewing or unclipping the panel from its mounting. Depending on the design, a methodical approach is necessary to avoid damaging the delicate solar cells.

Taking care is essential during this step, primarily due to the possibility of brittle material. The solar panel wiring should also be observed closely as it may be soldered or connected via a connector. Each situation will differ based on the manufacturer, making it vital to observe the attachment method before proceeding cautiously.

7. EXTRACTING THE BATTERY

Next in the disassembly sequence is the extraction of the battery, which often is securely housed within the core unit. In certain models, the battery may be held in place by additional screws or clips that need careful removal. Understanding the layout of the internal components helps streamline the extraction process.

Once the battery is fully visible, ensure to handle it with care. There is a risk of short-circuiting if terminals touch metal surfaces. When disconnected, batteries should be placed in a safe area where they will not be subject to unnecessary pressure or harm, as lithium batteries can pose significant safety hazards if damaged.

8. REMOVING THE CIRCUIT BOARD

The final stage of disassembly involves detaching the circuit board, which is critical for the overall operation of the solar light. This board is usually connected via soldered wires or connectors. Prior knowledge of these connections is important to prevent unintended damage during removal.

When detaching the circuit board, it is advisable to utilize a gentle rocking motion instead of force to displace any solder joints. This ensures that delicate components are not stressed, leading to an overall successful disassembly. Detailed attention to every aspect will yield the best outcome and assist in any potential reassembly.

FREQUENTLY ASKED QUESTIONS

HOW CAN I ENSURE SAFETY WHEN DISASSEMBLING AN IP67 SOLAR LIGHT?

In ensuring safety during the disassembly of an IP67 solar light, various precautions should be taken. Firstly, always ensure the device is powered off and disconnected from any electricity source. Covering the solar panel will help prevent accidental activation. Furthermore, using protective goggles and gloves minimizes injury risks from sharp edges or components. It is also crucial to work in a well-lit area with ample space to organize the components as they are removed. Consideration of the specific tools required for the job can facilitate smooth disassembly without damaging fragile components, maintaining safety at every phase.

WHAT SHOULD I DO IF I ENCOUNTER RUST OR CORROSION INSIDE THE LIGHT?

Should any rust or corrosion be identified during disassembly, it is vital to approach the situation with care. Firstly, it is important to determine the source of the corrosion, as this could indicate prolonged exposure to moisture, suggesting that the IP67 seal may have been compromised. Using a soft cloth, one can gently wipe away any corrosion, taking care not to damage surrounding components. If extensive damage is noted, it may be required to replace certain parts to restore functionality. Regular cleaning and maintenance following reassembly can prevent future occurrences of rust, prolonging the life of the solar light significantly.

CAN I REASSEMBLE THE LIGHT AFTER DISASSEMBLY?

Reassembly of the solar light is generally possible, provided that all components are intact. Each part should be returned to its original position, following the reverse order of disassembly. Pay careful attention to any connectors, ensuring they fit snugly without forcing them. If screws were removed, make sure they are returned to their respective positions, and do not forget to replace any seals or gaskets to maintain its IP67 rating. Testing the light in a controlled environment before permanent installation will ascertain that all components function as expected without issues. Proper reassembly is crucial for preserving the original protective features of the unit.

To conclude, disassembling an IP67 solar light requires a meticulous approach, emphasizing safety, technique, and awareness of the waterproofing design. Assiduous preparation is paramount; one must ensure that appropriate tools and gear are ready prior to embarking on the task. Protection protocols effectively mitigate the risks associated with electrical components and fragile structural elements. Emphasizing the specific sequence helps maintain organization and keeps parts accounted for while ensuring a systematic understanding of the unit’s internal architecture. All steps, from disconnecting power sources to extracting individual components such as the solar panel, battery, and circuit board, must be executed with precision and caution. This strategic disassembly process bolsters knowledge of the device while paving the way for repairs, replacements, or upgrades, all while preserving the integrity of the original structure. With adequate forethought and careful attention, those who undertake this task will find it rewarding as they journey into the inner workings of an IP67 solar light, ultimately returning it to service better than before.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-ip67-solar-light/