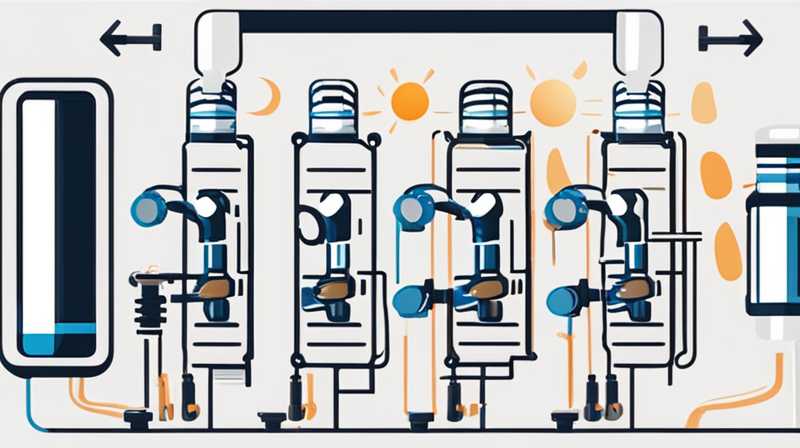

How to disassemble and install solar solenoid valve

To disassemble and install a solar solenoid valve, follow these steps: 1. Gather the necessary tools including a wrench, screwdriver, and pliers, 2. Disconnect power and water supply before beginning work, 3. Carefully remove the solenoid from its mounting location, 4. Replace the old valve with a new solenoid valve while ensuring proper alignment, 5. Reconnect the power supply and test the system for proper operation. Elaboration on one key point: Ensuring a safe disconnection of power and water is critical to prevent accidents and equipment damage. Taking the time to turn off the electrical supply and shut off the water flow will create a safer work environment and allow for a smoother installation process.

- UNDERSTANDING SOLENOID VALVES IN SOLAR SYSTEMS

An exploration of solar solenoid valves reveals their functional significance in modern renewable energy systems. These devices are essential for controlling the flow of fluids within geothermal and solar thermal energy applications. Often, they act as mechanisms to automate water flow in various thermal collectors and piping systems.

Typically, solenoid valves function by utilizing electromagnetic coils that, when energized, create a magnetic field to open or close the valve. Their efficacy in solar applications reduces the reliance on manual control and allows for dynamic response based on temperature changes. This automation is crucial for effective energy management in solar systems, making them indispensable for optimizing performance in eco-friendly designs.

Understanding the various components and operational principles of solenoid valves can significantly aid in the processes of disassembly and installation. Having thorough knowledge of how each part interacts within the larger system will result in a smoother workflow and fewer complications in the future.

- SAFETY PRECAUTIONS BEFORE DISASSEMBLY

Prior to initiating the disassembly of a solar solenoid valve, adhering to stringent safety protocols is paramount. Safety precautions can prevent injuries and accidental damage. Familiarity with local electrical codes and understanding the general operation of plumbing are essential prerequisites. Always begin with a thorough assessment of the workspace and tools.

To prevent any unintentional electric shock, it is imperative to disengage power sources before work commences. This includes turning off breakers linked to the valve system and confirming that the power is entirely cut off using a multimeter. Such verification serves as an additional layer of caution that safeguards the operator.

Similarly, the water supply must be shut off to avoid flooding the working area. It may be beneficial to employ bucket systems or towels in case of unexpected leaks. Engineers and technicians universally advocate for this step, reinforcing the notion that safeguarding one’s environment equates to maximizing efficiency in the process.

- DISASSEMBLY PROCESS

Once all safety precautions are rigorously observed, the actual process of disassembling the solar solenoid valve can begin. This task requires specific tools and a step-by-step methodology to ensure accuracy and efficiency. Start by removing any outer casings or covers that may hinder access to the valve itself.

Utilizing a wrench or pliers, carefully loosen and detach the valve from its connections. This often requires attention to the orientation of the valve to maintain a clear understanding of reassembly. Documenting or photographing each micro-step can offer visual guidance later on, enhancing the overall effectiveness of the procedure.

Once separated from the connection points, the solenoid can be detached. It is critical to handle internal components with care, as they may be delicate and sensitive to mishandling. Be sure to keep the internal springs and components organized, as they play an essential role in the function of the valve upon reinstallation.

- INSPECTING THE OLD SOLENOID VALVE

Before proceeding to the installation phase, an inspection of the old solenoid valve is crucial. This analysis can reveal why the original valve failed and help inform decisions regarding the new valve. Look for signs of corrosion, mechanical damage, or burns around the electrical connections.

An important factor to consider is whether any pieces have become worn out, such as o-rings or seals. These parts are often the first to fail due to wear from hot water exposure or improper maintenance. Any findings during this inspection phase should be documented meticulously, as they provide insights for selecting a more resilient replacement option.

Another critical element to assess is whether the electrical connections are intact and functional. A faulty electrical connection might have contributed to the malfunction, and ensuring that the new installation avoids similar pitfalls is essential for long-term viability.

- INSTALLING A NEW SOLENOID VALVE

With the old valve inspected, the next stage involves installing a new solenoid valve. It is vital to select a high-quality valve that matches the specifications necessary for your solar system. Compatibility is vital to ensure an effective flow control mechanism within the system. Proper alignment of the new valve is necessary, as incorrect positioning may hinder functionality.

Carefully position the solenoid valve into place, ensuring the inlet and outlet connections align with the piping system adequately. Utilizing the original mounting brackets ensures a secure fit. After verifying alignment, securely fasten the valve to avoid any future leaks or operational issues. It is wise to follow any torque specifications requried by the manufacturer to avoid overtightening or damaging the valve.

Next, connect the electrical wiring to the solenoid. Always adhere to the manufacturer’s wiring diagrams and electrical safety standards. Proper connections ensure that the solenoid operates effectively and performs its intended function seamlessly during operation.

- TESTING THE INSTALLATION

Once the new valve is installed, the subsequent step involves a series of tests to validate functionality. Always restore the water supply gradually, allowing for any potential air pockets to clear from the system. Observing closely during this process can reveal any leaks or irregularities that might need immediate attention.

Following the water supply restoration, the power should also be re-engaged. Check that the solenoid valve operates as intended, responding to control commands. Monitor for any unusual noises or erratic behavior. Proper operation reflects not only the integrity of the installation but also the performance of the selected solenoid valve.

Once satisfied with the valve’s responsiveness, follow-up checks should be routinely scheduled, emphasizing long-term maintenance. Allowing continuous monitoring can prevent future malfunctions and ensure optimal performance from the solar system.

- MAINTENANCE TIPS FOR LONGEVITY

To extend the lifespan of the newly installed solenoid valve, incorporating a maintenance regimen is essential. Regular inspections can avert costly repairs and downtime in the system. Part of a preventive strategy includes cleaning the area around the valve and ensuring that dirt or debris does not obstruct operation.

Scheduled checks of electrical connections are vital. Worn wires can lead to malfunctions and pose safety hazards. Additionally, using protective casings can shield the solenoid from environmental factors, which is especially important in outdoor installations.

Another valuable practice is to monitor water quality within the solar system. Contaminants can wear down internal components, including seals or ports. Maintaining clean water not only protects the solenoid but improves the efficiency of the overall system, ensuring a consistent energy yield.

8. UPGRADING TO SMART VALVES

With advances in technology, many solar systems can benefit from implementing smart solenoid valves. These automated systems offer enhanced monitoring and control, allowing operators to manage fluid flow based on real-time data. Smart valves can integrate seamlessly with energy management systems, optimizing resource use effectively.

When considering an upgrade, assess what metrics are critical for your installation. Connectivity and usability of the software interface can greatly impact operational efficiency. Invest in smart valves that offer customizability to tailor to your specific needs and preferences.

The installation of smart solenoid valves can dramatically improve system responsiveness and overall management. They can be programmed to adhere to specific parameters based on environmental changes, leading to far superior resource utilization.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SOLENOID VALVES ARE BEST FOR SOLAR SYSTEMS?

In solar systems, selecting the appropriate type of solenoid valve hinges on various factors, including fluid type, pressure, and temperature ranges. Generally, two-way and three-way solenoid valves are favored. Two-way valves control flow in one direction, making them suitable for straightforward applications. Conversely, three-way valves can direct flow between two paths and are advantageous in more complex setups.

Choosing materials also plays a crucial role. Stainless steel or plastic valves are commendable due to their resistance to corrosion and heat. Additionally, verify that the solenoid valve has the necessary electrical ratings to ensure safe and efficient function. Consulting with professionals may provide insights tailored to individual solar setups.

HOW OFTEN SHOULD I INSPECT MY SOLENOID VALVE?

The frequency of inspections for solenoid valves largely depends on their usage and the specific setup of your solar system. It is advisable to implement a routine check twice a year under normal operational conditions. However, if your system is subject to extreme environmental stressors, monthly inspections may be warranted.

Inspecting includes observing for signs of wear, unusual noises, and potential leaks. Regular maintenance and timely replacements of worn components can preempt larger issues, thereby substantially enhancing the longevity of the system. Additionally, keep accurate records of every inspection and maintenance activity to track any emerging patterns.

WHAT IS THE SIGNIFICANCE OF USING GENUINE REPLACEMENT PARTS?

Using genuine replacement parts when repairing or upgrading your solenoid valve is crucial to maintain quality and compatibility. Counterfeit or generic alternatives may not meet specific design requirements, leading to operational inefficiencies or risking complete failure. Authentic components undergo rigorous testing and are manufactured to exact specifications, ensuring smooth integration.

Moreover, genuine parts often carry a warranty, which provides additional peace of mind. When considering the overall investment in a solar energy system, ensuring the reliability of every component, including its solenoid valve, is essential for maximizing energy efficiency and reducing long-term costs.

In summary, the disassembly and installation process for a solar solenoid valve requires careful planning and attention to detail. Proper safety measures, thorough inspections, and routine maintenance are key components of a successful installation. Additionally, investing in high-quality parts and embracing technological advancements can enhance performance. Regular monitoring and smart practices ensure the longevity of the entire solar system, maximally benefiting its users while reducing environmental footprints. With diligence in these aspects, one can experience lasting advantages from solar energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-install-solar-solenoid-valve/