To successfully disassemble and assemble a solar shifter, one should follow a methodical approach encompassing critical steps involving tools, safety measures, and assembly techniques. 1. Understanding the components and mechanisms, 2. Gathering the necessary tools, 3. Following a systematic disassembly process, 4. Implementing proper assembly procedures, and 5. Testing and troubleshooting post-assembly are essential for ensuring functionality and longevity.

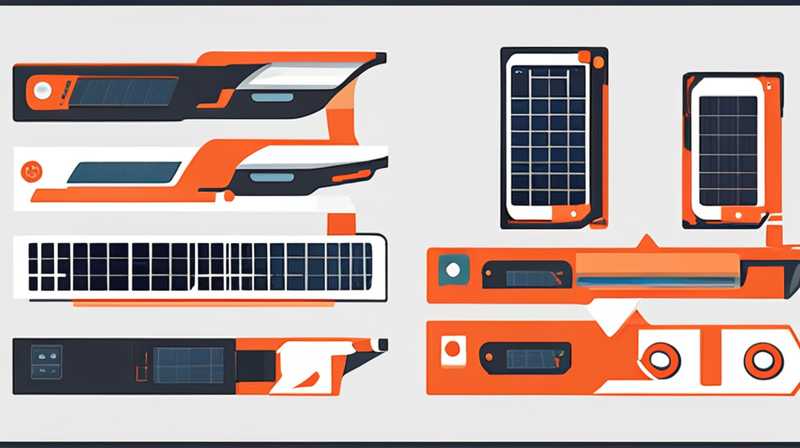

When considering understanding the components and mechanisms, it is vital to be aware of the various parts that constitute the solar shifter. Familiarity with the fundamental workings of this device, including its solar panels, battery systems, and control mechanisms, sets the foundation for a successful project. Having a comprehensive understanding will facilitate a smoother disassembly process, reducing the risk of damage or error.

In the next section, attention will focus on the tools required, including specific types that augment safety and efficiency, as well as the safety measures necessary to protect both the individual and the equipment involved.

1. UNDERSTANDING THE COMPONENTS AND MECHANISMS

Disassembling a solar shifter requires an intricate understanding of its various components. The solar shifter typically includes solar panels, a battery unit, controllers, and mechanical parts designed to facilitate the tracking of sunlight for optimal energy absorption. Each element plays a pivotal role and has to be handled with precision to maintain its integrity.

Solar panels convert light from the sun into electrical energy, and it’s essential to take precautions to avoid damaging them during the disassembly. Batteries store this electrical energy and should be managed carefully, as improper handling can lead to leaks or damage. Controllers are necessary for managing voltage and current to ensure the system operates efficiently, whereas mechanical parts allow for the movement of the solar panels that chase sunlight. Understanding how these components interact will lead to a more effective approach when attempting to disassemble the equipment.

Additionally, recognizing the connection types and fixture points is equally crucial. Thorough knowledge of screw types, wiring configurations, and any clips or adhesive bonds utilized in the assembly will aid in ensuring each part can be removed or separated without causing harm. Familiarization with each of these elements not only paves the way for a successful disassembly but also sets the stage for proper reassembly.

2. GATHERING THE NECESSARY TOOLS

Before initiating the disassembly of a solar shifter, it is imperative to gather a comprehensive set of tools. Utilizing the appropriate equipment enhances safety and maximizes efficiency during the process. Fundamental tools for this procedure may include screwdrivers, wrenches, wire cutters, and gloves. Each tool serves a specific purpose that aids in completing the task without hitches.

Screwdrivers, for instance, come in various sizes and types, including Phillips and flathead, which are suited for differing screw designs found throughout the device. Wrenches serve to loosen nuts that can be pivotal in accessing internal components. It is advisable to select tools that are of high quality to prevent stripping screws or damaging components during disassembly. Furthermore, wire cutters are essential if any wiring needs to be disconnected or adjusted.

In addition to tools, safety gear must be included in the preparation. Gloves are recommended to protect hands from sharp edges or accidental pinching as parts are separated. Safety goggles provide additional protection for the eyes, particularly when working with electronic equipment, where small components may spring unexpectedly. Ensuring proper tools and safety measures are in place will greatly reduce the risks associated with the disassembly process.

3. FOLLOWING A SYSTEMATIC DISASSEMBLY PROCESS

Embarking on the disassembly of a solar shifter should be executed in a methodical manner. Failing to adhere to a systematic approach can result in lost parts or damage to components. Start with a clear workspace free from distractions and clutter. This organized environment aids in maintaining focus and allows ample space to lay out parts as they are removed.

Documenting the current configuration of the solar shifter before disassembling is highly recommended. Taking photographs from several angles captures the original setup, which will serve as a useful reference during reassembly. It is wise to label wires and components as they are disconnected to avoid confusion later on.

As the disassembly progresses, tackle the innermost components first, gradually working towards the outer sections. Begin by removing any shields, covers, or protective casings that expose internal mechanisms, often held in place by screws or clips. Removing these safeguards allows for greater access to the solar panels’ wiring and battery connections. Each component should be handled with care to prevent any irreversible damage.

To ensure that all parts are accounted for, creating a parts checklist can be beneficial. This list enables easy tracking of components throughout the disassembly phase, thereby minimizing the risk of loss. Every element should be put in designated areas to prevent mixing or misplacing crucial parts.

4. IMPLEMENTING PROPER ASSEMBLY PROCEDURES

Reassembling a solar shifter is as crucial as disassembly and should be approached with the same level of care and deliberation. Following the methodically documented steps can significantly enhance the success rate of reassembly. Begin with the internal components, ensuring they are arranged in the same manner as documented during disassembly. This drawing on previous notes will mitigate the risk of errors.

Before securing components in place, ensure all connections are clean and free from debris. This may include checking battery terminals and verifying that solar panel wiring is intact and correctly aligned. Proper alignment of all parts guarantees that the device will function as intended once reassembled.

When tightening screws or securing any fasteners, exercise caution not to over-tighten, as this could lead to stripping threads or damaging delicate components. A sufficient grip is crucial to keep the parts in place without causing undue stress to them. Furthermore, refer back to the initial photographs and notes taken during disassembly. This practice provides clarity and guides one back to correct placements of components, wires, and other fixtures.

Once the entire assembly process is complete, the next step will be to conduct a thorough inspection of the solar shifter to ensure everything has been installed correctly and securely. This stage marks a critical juncture before operating the device, where any discrepancies can be resolved preemptively.

5. TESTING AND TROUBLESHOOTING POST-ASSEMBLY

After successfully assembling the solar shifter, testing is of paramount importance. A thorough functionality check is necessary to determine that each component is operating correctly and efficiently. Begin by verifying that the solar panels are connected properly and that the wiring shows no signs of damage. Testing should be carried out under initial sunlight, allowing the solar panels to convert sunlight into electrical energy.

Observing the output high and verifying that the battery charges appropriately will confirm that the system operates as intended. Any discrepancies, such as failure to charge or unusual noises, should prompt further examination. In dealing with complications, refer back to the documentation and ensure all wiring is correctly configured.

Moreover, should challenges arise, troubleshooting may become necessary. Common issues include poor connection contacts or components jammed from improper reassembly. Identifying these glitches often requires a systematic review of the assembly process, ensuring that nothing has been overlooked. In situations where complex difficulties persist, consulting manufactured guidelines or experts in the field can provide additional insights.

Testing and troubleshooting are crucial stages that determine the longevity of the solar shifter and its operational functionality. Addressing these areas diligently will assure the device’s performance meets expectations and provides sustainable energy as designed.

QUESTIONS FREQUENTLY ASKED

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING A SOLAR SHIFTER?

A comprehensive array of tools is fundamental for effectively disassembling a solar shifter. Essential equipment includes a set of screwdrivers, with both Phillips and flathead variants to accommodate different sizes and types of screws found. Additionally, wrenches are necessary for loosening any nuts that may hold critical components in place. Providing versatility are wire cutters, which can aid in disconnecting wires safely.

Personal protective gear, including gloves and safety goggles, is mandatory to prevent injury during the disassembly process. Gloves protect the hands from sharp edges and ensure a firm grip without risking slippage. Safety goggles safeguard the eyes against potential debris or parts that may spring during removal. Utilizing these tools effectively can lead to a smoother disassembly process and ensure safety throughout the efforts.

Additionally, having a multimeter can be advantageous for assessing electrical connections and battery voltage during the process, providing a detailed understanding of component effectiveness. By carefully selecting and utilizing the appropriate tools, one can streamline the disassembly and significantly reduce the likelihood of damaging any parts.

HOW DO I KNOW IF MY SOLAR SHIFTER WORKS CORRECTLY AFTER REASSEMBLY?

Validating the operation of a solar shifter post-reassembly entails a systematic approach that primarily focuses on functional checks and performance assessments. The initial step involves ensuring all connections are secure and systematically aligned as per the documentation taken during disassembly. Upon confirming correct assembly, place the solar shifter under optimal sunlight conditions to observe its energy conversion capabilities.

Monitor the output levels generated by the solar panels and cross-reference them with the specifications provided by the manufacturer. Confirming that the battery charges adequately within a certain timeframe is a key indicator that everything has been assembled correctly. In addition to visually inspecting the solar panels to ascertain they’ve been correctly positioned, listen for any abnormal noises during operations, which may signal mechanical issues.

In the event that the solar shifter fails to operate correctly, it is advisable to retrace assembly steps. Verify all wiring connections for proper alignment, ensuring no wires are frayed or disconnected. Additionally, re-examine all fastened components to check for over-tightened screws which could result in stress and hinder functionality. Should issues persist, consulting technical documentation or reaching out to experts may offer further insights.

WHAT COMMON MISTAKES SHOULD I AVOID WHEN DISASSEMBLING OR ASSEMBLING A SOLAR SHIFTER?

A variety of pitfalls can emerge during the disassembly and assembly of a solar shifter, and being aware of these can greatly enhance the process. One prevalent mistake is a lack of organization. Without proper labeling and documentation of parts, individuals may misplace components, leading to confusion or incorrect placements during reassembly. Prioritizing a systematic method of component tracking, such as creating a parts checklist, will mitigate this issue.

Neglecting safety measures can also lead to unwanted incidents. Failing to use protective gear like gloves or goggles can result in injuries from sharp edges or unexpected debris. Ensuring safety should always be paramount when handling electric and mechanical devices.

Another notable mistake is over-tightening connections during reassembly. Applying excessive force when securing components can lead to thread stripping or damage to delicate parts. It is critical to apply sufficient torque without exceeding necessary limits. Additionally, remember to regularly reference manufacturer’s guidelines and assembly instructions as a safeguard against errors.

Conducting thorough inspections and tests both before disassembly and after assembly creates a safety net. These comprehensive checks ensure that every aspect functions, grammar errors aren’t present, and performance meets expectations.

FINAL THOUGHTS

Addressing the intricacies involved in disassembling and reassembling a solar shifter can significantly influence its lifespan and operational effectiveness. Acquainting oneself with all components, conducting careful disassembly, and following a systematic approach to reassembly are paramount to achieving desired outcomes. Proper tools, safety measures, and thorough testing all contribute to a seamless process, aligning with both personal goals and sustainable energy solutions.

Throughout, meticulous documentation serves as a valuable resource. Recording the initial configuration, the steps taken during disassembly, and the reassembly process allows for a reliable reference. Implementing this strategy enhances the likelihood of a successful outcome while minimizing errors.

Undoubtedly, the solar shifter stands as a testament to how technological advancements enable us to harness renewable resources. It is imperative that individuals take the proper precautions and apply their understanding effectively. Thus, by developing a structured approach, engaging with the material knowledgeably, and ensuring a high level of attentiveness during both disassembly and assembly, one maximizes the potential of this innovative device. Through this diligence, the solar shifter can continue to support sustainable energy endeavors, contributing positively to both individual needs and environmental goals.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-the-solar-shifter/