To disassemble and assemble a solar overflow pipe effectively, one must follow a systematic approach to ensure proper functionality and avoid any damage. 1. Understanding the components is crucial, 2. Appropriate tools are necessary, 3. Safety precautions must always be adhered to, 4. Reassembly should ensure leak prevention.

Understanding the Components

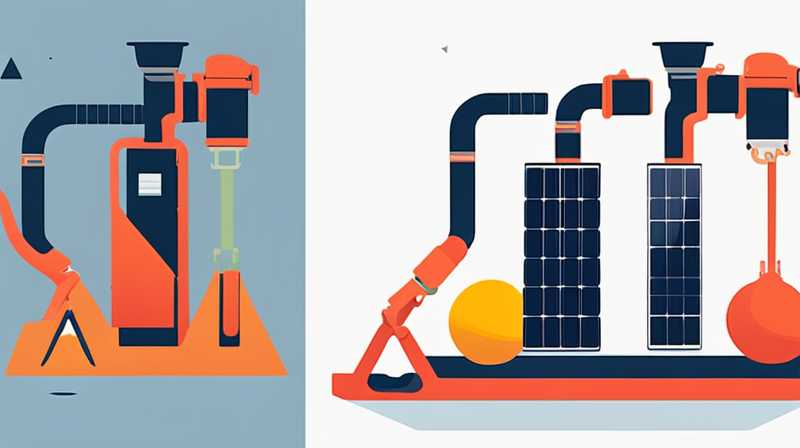

Grasping the various elements of a solar overflow pipe is imperative before embarking on the task of disassembly or assembly. Solar overflow pipes are part of a solar thermal system, designed to provide excess pressure relief for fluids circulating through solar collectors. They typically comprise connectors, the overflow pipe itself, and a reservoir. Each component plays a pivotal role in maintaining optimal system performance and preventing water damage or inefficiencies in the solar system.

The connectors, often made of durable materials like PVC or brass, provide links between the solar collectors and the overflow mechanism. Understanding how these connectors interlink with the overflow pipe ensures a seamless disassembly and assembly process. Proper identification of all parts aids in preventing potential errors that could lead to leaks or system malfunctions.

Appropriate Tools

Equipping oneself with the correct tools is essential before transforming the solar overflow pipe. The tools needed generally include a wrench, a screwdriver set, pliers, and possibly a pipe cutter for any repairs required. The wrench is pivotal for loosening and tightening connections, while pliers are valuable for gripping the more intricate components. A comprehensive toolkit not only facilitates effective disassembly but also ensures a smoother reassembly.

Having the right tools on hand plays a significant role in expediting the process. Investing time in gathering all necessary equipment prior to initiating any work can prevent confusion or interruption, ultimately leading to a more streamlined operation. Each tool must be inspected for wear, as damaged or unsuitable equipment can lead to unexpected complications.

Safety Precautions

Safety should be prioritized throughout the entire process of disassembling and assembling the solar overflow pipe. Before commencing, it is crucial to disconnect the system from any power source to prevent electrical hazards. Additionally, wearing protective gear, such as gloves and goggles, guards against potential injuries from sharp components or debris.

Proper ventilation is another vital aspect, particularly if any maintenance involves the use of chemicals or involves cleaning agents. Always ensure that the workspace is clear of hazards to prevent accidents during the disassembly. Furthermore, informing any other personnel in the vicinity about the ongoing work promotes safety awareness, significantly reducing the risk of injuries or mishaps.

Reassembly and Leak Prevention

Once the disassembly is complete, it is time to focus on reassembly. This stage is equally critical, as improper reassembly can result in leaks, which could cause extensive damage to both the solar system and surrounding areas. Begin by carefully aligning all components as they were originally configured. Ensure that all seals and gaskets are intact and in good condition before placing components back together. It’s advisable to use new seals if existing ones show signs of wear, as this can prevent many future issues.

After assembling the components, conduct a thorough inspection before reactivating the system. Inspect for any visible gaps or misalignments that could potentially lead to leaks. Activating the system gradually while watching for unusual sounds or leaks can help catch issues before they lead to more significant problems. This methodical approach ensures that the solar overflow pipe functions properly while safeguarding the integrity of the overall solar thermal system.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR OVERFLOW PIPE, AND WHY IS IT ESSENTIAL?

A solar overflow pipe functions as a vital component of solar thermal systems, ensuring that excess pressure is released safely from the system. When the temperature of the fluid in the solar collectors rises beyond a specified limit, the overflow pipe allows for the escape of fluid, preventing possible damage from excessive pressure buildup. This mechanism not only protects the integrity of the solar system but also ensures that the system operates efficiently. Additionally, by managing pressure effectively, it helps maintain the longevity of essential components. The proper understanding and maintenance of this element are critical for any solar system’s reliability and performance.

HOW OFTEN SHOULD I CHECK OR MAINTAIN MY SOLAR OVERFLOW PIPE?

Regular inspections of the solar overflow pipe are recommended at least twice a year, particularly before and after the hot summer months. These checks should focus on detecting wear, leaks, or blockages that could impair functionality. Additionally, maintaining a routine during seasonal changes ensures that the system remains efficient year-round. Routine maintenance checks should also coincide with regular service inspections of your solar thermal system to facilitate optimal performance. However, if the system is exhibiting unusual sounds, leaks, or pressure fluctuations, immediate inspection and maintenance are necessary to prevent significant issues from developing.

WHAT ARE COMMON ISSUES ENCOUNTERED DURING REASSEMBLY, AND HOW CAN THEY BE RESOLVED?

Common challenges during reassembly of the solar overflow pipe can include misalignment of connectors, insufficient sealing, and mishandling of components. Misaligned connectors often arise from incorrect positioning or failure to tighten connections properly. This can lead to leaks and must be addressed immediately by realigning and securely tightening those connections. Insufficient sealing may result from worn-out gaskets or seals; replacing these is crucial to prevent leakage. Furthermore, mishandling components can lead to cracks or breaks in the pipes themselves, necessitating careful attention and support during assembly to ensure integrity. Recognizing these common pitfalls can guide individuals in carrying out effective reassembly, preserving the entire system’s function.

It is imperative to emphasize the importance of meticulous attention to detail throughout the entire process of disassembling and reassembling the solar overflow pipe. Ignoring any facet, whether it be safety protocols, the proper utilization of tools, or the direct performance of each component, can result in significant complications, including inefficiencies and potential damage to the broader solar thermal system. Mastery over these tasks not only enhances the performance of solar energy solutions but also contributes to long-term sustainability practices essential for an eco-friendly future. Proper training and preparation can elevate outcomes, ensuring that individuals undertaking this assignment are equipped with the knowledge necessary to execute each step proficiently. As a result, understanding the requisite procedures and maintaining a high degree of care can foster a more robust solar thermal system while promoting environmental responsibility and longevity in the usage of solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-the-solar-overflow-pipe/