To disassemble and assemble a solar glass tube involves a specific sequence of steps that ensure the integrity of the components while handling them safely. 1. Safety precautions are paramount; 2. Use appropriate tools; 3. Follow sequential disassembly; 4. Ensure proper reassembly. The process requires careful attention to detail to avoid damage and to facilitate optimal functioning. It is crucial to wear protective gloves and goggles to prevent injury while working with glass. Proper tools such as screwdrivers, wrenches, and a clean workspace contribute to an efficient task. Carefully documenting each step taken during disassembly allows for smooth reassembly, ensuring all components fit correctly and securely.

1. IMPORTANCE OF SOLAR GLASS TUBES

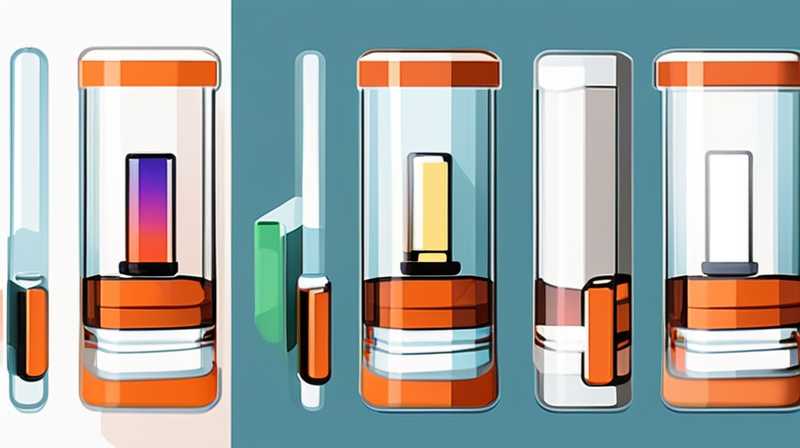

Solar glass tubes serve as a vital part of solar thermal systems, converting solar energy into usable heat for various applications, including water heating and space heating. They utilize a vacuum between two layers of glass that enhances thermal efficiency by reducing heat loss, making solar collectors significantly effective in both residential and commercial settings. Understanding their function and importance is crucial for any technician or enthusiast engaged in solar energy systems.

The design of these tubes is derived from principles of physics and engineering that maximize sunlight absorption while minimizing energy loss. Consequently, addressing issues related to the integrity or functionality of these tubes by learning how to properly assemble and disassemble them can lead to prolonged system life and increased efficiency in energy conversion. Mastery of this technique directly impacts the overall performance of solar systems, which aligns with a growing emphasis on sustainability and renewable energy sources.

2. TOOLS REQUIRED FOR DISASSEMBLY AND ASSEMBLY

Proper tools are indispensable for successfully handling the disassembly and assembly of solar glass tubes. Essential tools include screwdrivers, wrenches, pliers, and safety gear, among others. Each tool plays a critical role in ensuring the process is executed smoothly without causing damage to the components.

Screwdrivers, particularly Philips and flathead types, are necessary for removing screws that hold structural components together. Wrenches, including both adjustable and fixed types, allow for the loosening and tightening of nuts that are often present in the assembly of solar tubes. Pliers can be particularly useful for gripping and manipulating small components, especially when dealing with tight spaces.

In addition to these primary tools, personal protective equipment (PPE) is crucial. Gloves can protect hands from cuts or abrasions from sharp edges, while goggles safeguard the eyes from potential glass splinters or debris. Having a clean, organized workspace is also a key factor that aids in effectively managing the parts while ensuring nothing is misplaced during the entire process. Properly equipping oneself sets the foundation for a successful operation.

3. SAFETY PRECAUTIONS DURING THE PROCESS

When engaging in the disassembly and assembly of solar glass tubes, safety must be prioritized. Take precautions to mitigate the risk of injury from sharp glass edges and fragile materials. Knowledge of safe handling practices contributes to preventing accidents and damage.

Before commencing the task, ensure that the glass tubes are cool and not exposed to any residual heat, as this can lead to thermal shock. If working with tubes that have been in use, allow them to cool down completely to avoid burns or thermal cracks during disassembly. Additionally, inspect the workspace for hazards, and clear any obstacles or distractions that may interfere with the task.

Furthermore, working with a partner can be valuable—having an extra set of hands can prevent drops and falls, especially when handling larger or heavier components. If necessary, employ specialized handling equipment, such as lifters or dollies, to safely manage bulk tubes. Clear communication with any assisting personnel is essential to ensure actions are synchronized, thus minimizing risk.

4. STEP-BY-STEP DISASSEMBLY GUIDE

Disassembling a solar glass tube should be executed with precision and methodical practice. Begin by removing any external fixtures or supporting elements. This process is often outlined in the manufacturer’s guidelines, providing a roadmap to safely detach each component.

Start by removing screws or bolts that secure the solar collector panel if present. Use the appropriate screwdriver or wrench to loosen these fasteners before proceeding. Carefully set aside screws in a designated container to avoid loss. Following this, assess the connections that secure the glass tube to its mounting frame.

Once disconnected, attention should turn towards separating the glass tube from any fixed or movable parts. Gently wiggle the tube while securing the framework, thereby loosening its grip. If the tube resists, verify if there are any additional fittings or adhesives used. Never force components apart, as this may lead to breakage. It’s vital to meticulously document the order in which the components are removed, as this will significantly simplify the reassembly process.

5. PREPARATION FOR ASSEMBLY

Preparation is a critical aspect when transitioning from disassembly to reassembly of solar glass tubes. Begin by organizing all components methodically, ensuring nothing is missing and that every part is intact. Inspect each component for signs of wear or damage that may require replacement before reassembly takes place.

Thorough cleaning of all components is vital, especially the contacting surfaces where seals may be required. Any dirt, debris, or old adhesive left on the surfaces can hinder the efficiency of the reassembly. Use appropriate cleaning solutions and methods to maintain integrity while performing this step.

Additionally, gather the necessary tools, ensuring they are in good working condition and easily accessible. Reviewing the documentation from the manufacturer can serve as a guide to understand how parts fit together and make sure no adjustments are overlooked. Confirming that all required tools are at hand before assembly can prevent unnecessary interruptions and allow for a smoother workflow.

6. STEP-BY-STEP ASSEMBLY GUIDE

The process of reassembling a solar glass tube is just as critical as disassembly, and following a systematic approach is key to ensuring success. Begin by aligning the components according to the order observed during disassembly. This not only streamlines the process but also reduces the chance of errors.

Start with the mounting frame and ensure it is properly secured and stable. Place the glass tube within its designated place, ensuring that it is correctly oriented. If any fittings, such as rubber gaskets or seals, are to be used, ensure they are installed properly to prevent leaks. Make adjustments as needed, ensuring all parts are snug yet not overly tightened, which can strain the glass.

Next, progressively fit the remaining components, again following the order noted during disassembly. Ensure each part connects seamlessly and remains aligned without obstruction. Once fully assembled, examine all connections before proceeding to secure them with the final tightening, ensuring the whole structure holds firmly in place.

7. COMMON ISSUES AND TROUBLESHOOTING

After working on solar glass tubes, one may encounter issues that could impact functionality. Recognizing common problems enables effective troubleshooting, ensuring the solar system operates optimally.

One common issue is leaks at the junction of connections. If this occurs, it might indicate that fittings are not secured appropriately. The solution involves disassembling the affected area, inspecting seals, and reapplying adhesive if necessary before reassembling securely.

Additionally, cracks in the glass tubes themselves may emerge from improper handling or thermal shock. In such cases, one must replace the damaged section to maintain the overall system’s effectiveness. If cracks are minimal and do not impact thermal efficiency, however, one can consider using specific sealing solutions recommended by manufacturers.

Misalignment of parts during assembly can cause operational inefficiencies. If performance remains below expected levels, a complete check on the alignment and connection is warranted to rectify any discrepancies immediately and redefine optimal functioning.

8. FOLLOWING BEST PRACTICES

To ensure longevity and performance in solar glass tube systems, adhering to best practices is essential. Regular maintenance checks and proper usage are paramount. This includes periodically inspecting the tubes for any signs of wear, cleaning and reassessing connections for tightness.

Training on handling procedures can also prevent accidents and extend the life of the components. Engaging in continued education about advancements in solar technology can impart knowledge that enhances operational skills.

Incorporation of a detailed documentation process allows for equipment tracking, ensuring maintenance histories are maintained and any new findings or upgrades are logged. This creates a robust system capable of efficiently capturing solar energy, contributing effectively to sustainable practices.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR GLASS TUBE AND HOW DOES IT WORK?

A solar glass tube is an integral component of solar thermal systems designed to capture sunlight and convert it into heat through a vacuum-sealed environment. These tubes have an inner and outer layer of glass, which forms an insulating vacuum in between. The sun’s rays pass through the outer glass and heat the inner layer, which is often painted to optimize absorption. This heated element transfers warmth to a working fluid, such as water, circulating it for heating applications or storing it for later use. A key advantage of this design is its enhanced efficiency in capturing and maintaining heat, thus maximizing the overall performance of solar thermal collectors.

HOW CAN I ENSURE THE LONGEVITY OF MY SOLAR GLASS TUBES?

To extend the lifespan of solar glass tubes, consistent monitoring and maintenance are essential. Regular inspections for signs of wear or damage should be a fundamental practice, with immediate repairs conducted when needed. Maintaining a clean surface assists in maximizing sunlight absorption, thus improving efficiency. Avoiding direct harsh impacts during cleaning or maintenance further reduces the risk of breakage. Additionally, ensuring that all connections and fixtures are secured properly prevents strain on the tubes over time. Regularly consulting with professionals for an assessment or maintenance can provide valuable insights into ensuring optimal functioning.

IS IT SAFE TO DISASSEMBLE AND ASSEMBLE SOLAR GLASS TUBES MYSELF?

While disassembling and reassembling solar glass tubes can be executed safely by knowledgeable individuals, adherence to safety protocols is critical. Comprehensive understanding of the process, combined with the right tools and protective gear, improves safety. Ensure you are meticulously following guidelines provided by the manufacturer or industry standards. Should the project feel overwhelming or if uncertainty arises, consulting a professional is advisable. A qualified technician can provide expert assistance, ensuring that both safety and operational efficiency are maintained at all times throughout the procedure.

Engaging in the process of disassembling and assembling solar glass tubes necessitates meticulous attention to detail and adherence to safety standards. The process ensures that not only are the components correctly installed and functioning, but it also contributes to maintaining the overall efficiency of solar systems that rely on these crucial elements. Learning how to navigate this task effectively allows individuals or technicians to manage repairs or installations with greater confidence and promotes better energy performance. Furthermore, embracing a culture of regular maintenance enhances system lifespans and bolsters the adoption of renewable energy solutions overall. Each component within a solar glass system plays a distinct role in the collective functioning of the solution, and each aspect must be treated with care and consideration to achieve the desired outcomes in energy efficiency. As global attention turns towards sustainable energy resources, expertise in areas such as these becomes invaluable, fostering growth in skill sets that support innovative energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-the-solar-glass-tube/