Disassembling and reassembling an old solar panel requires careful attention to detail and adherence to safety protocols. 1. Understanding the Structure: It is crucial to familiarize oneself with the components of a solar panel, which includes a glass cover, photovoltaic cells, and a backing material. 2. Tools Needed: Essential tools for this procedure include a screwdriver, safety goggles, and a multimeter, to ensure effective handling and measurement of electrical components. 3. Safety Precautions: Ensuring that the solar panel has been disconnected from any power source is vital for safety. 4. Reassembly Process: Once disassembled, careful organization of parts will streamline the reassembly, ensuring optimal functionality of the solar panel.

1. UNDERSTANDING THE STRUCTURE

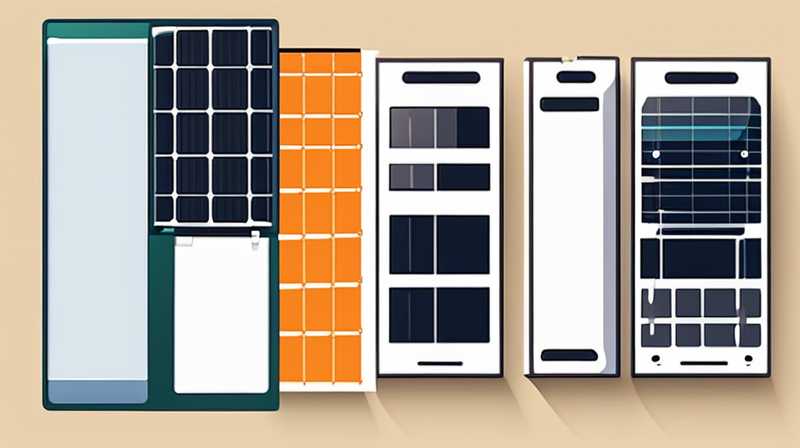

A solar panel is a complex assembly of various elements working in unison to convert sunlight into electricity. Familiarity with its structure is fundamental for successful disassembly and reassembly. The primary components include a protective glass layer, photovoltaic cells, and an aluminum frame, typically encasing a combination of silicon and semiconductor materials.

The glass cover serves both protective and aesthetic functions. While it shields delicate internal mechanisms from environmental elements, it also enhances the efficiency of light absorption. Photovoltaic cells, the heart of the solar panel, are responsible for the conversion of solar energy to electrical energy. These cells generate direct current (DC) electricity upon exposure to sunlight. Understanding the role of each part will facilitate a more efficient disassembly process.

2. TOOLS NEEDED

Before initiating the disassembly process, gathering the necessary tools is critical. Essential equipment includes a screwdriver, which enables access to the screws holding the solar panel’s frame intact, accompanied by safety goggles to protect one’s eyes during the procedure. A multimeter plays a pivotal role in measuring the electrical output and ensuring no residual charge remains in the cells before beginning work.

Moreover, having a soft cloth on hand is advantageous for cleaning glass surfaces during the reassembly process, ensuring maximum light transmission once the panel is reattached to its setup. Using proper tools not only ensures safety but also promotes the longevity of both the panel and the maintenance process. The organization during this phase reflects significantly on the outcome once reassembly begins.

3. SAFETY PRECAUTIONS

Prior to embarking on the disassembly task, it is imperative to prioritize safety precautions. Ensuring that the solar panel is completely disconnected from any power source is vital as it reduces the risk of electrical shock. Solar panels often retain some charge even when not in active use; therefore, testing with a multimeter to confirm the absence of electrical current is recommended.

Wearing gloves further enhances safety by protecting hands from sharp edges and glass shards. A well-lit workspace contributes to a safer environment by minimizing chances of accidents. Additionally, working on a stable surface prevents any unwanted shifts during disassembly. These precautions play an essential role in not only safeguarding one’s well-being but also in preserving the integrity of the solar panel components.

4. DISASSEMBLING THE SOLAR PANEL

The disassembly process begins with carefully removing the aluminum frame that encases the panel. Starting at one corner, use a screwdriver to loosen screws gradually, ensuring not to strip them. As the frame becomes detached, it is advisable to maintain an organized workspace where each removed component can be placed in an easily accessible manner. This not only saves time but minimizes confusion during reassembly.

After the frame has been successfully removed, the next stage involves detaching the glass cover from the photovoltaic cells. This step requires patience and care to prevent damaging the glass or cells beneath. Gently prying the glass apart from the panel may require the use of a plastic tool, which serves to prevent scratches or cracks. Once the glass is removed, inspecting the photovoltaic cells for any damage is critical, as this phase provides an opportunity for repairs before reassembly.

5. INSPECTING COMPONENTS

Following disassembly, it is vital to meticulously examine each component of the solar panel. Inspecting photovoltaic cells for any cracks or discoloration can determine the efficiency of the panel once reassembled. Note that any visible damage can significantly compromise overall performance, hence requiring either repair or replacement. Tools such as a multimeter can help in testing the output of the cells, ensuring they function as intended.

Likewise, the electrical connections should be assessed for any signs of corrosion or wear. Connection integrity is crucial to ensure that electricity flows freely without interruption once reassembled. Should any issues be detected, replacing wires or connectors at this stage can prevent future malfunctions and contribute to a more reliable solar energy system.

6. CLEANING AND MAINTAINING

Once all components are inspected, cleaning the glass surface is essential for enhancing light absorption efficiency. Dust, grime, and other residues can obstruct sunlight, thus affecting the panel’s energy output. Employing a soft cloth and a mild detergent can restore the glass to optimal clarity without scratching the surface.

When reassembling the photovoltaic cells, ensure they are not only connected properly but also shielded from dust or moisture. Utilizing insulating materials can help to safeguard connections and enhance overall durability. Moreover, securing every component firmly will prevent them from loosening over time due to environmental factors or vibrations.

7. REASSEMBLING THE SOLAR PANEL

The final phase of this process involves carefully reassembling the solar panel. Begin by placing the cleaned glass cover back onto the photovoltaic cells, ensuring a snug fit without applying excessive force. It is important to reapply the same screws gently to avoid damaging the glass or any underlying parts. Each screw should be tightened uniformly to maintain balance and prevent stress on any individual section of the panel.

After securely attaching the glass, reattach the aluminum frame. Again, precision in screw tightening ensures that no gaps remain, which could allow moisture to infiltrate. Once completed, checking for any signs of instability or misalignment before testing the functionality of the solar panel is advisable. A final inspection ensures that the entire structure retains its integrity and operates efficiently.

8. TESTING FUNCTIONALITY

After the reassembly is finalized, it is crucial to verify the solar panel’s functionality. Using a multimeter, measure the output of the photovoltaic cells to confirm they are generating electricity as intended. Ensuring a proper voltage output indicates a successful reassembly, while discrepancies might suggest that further examination or adjustments are necessary.

Positioning the solar panel back in its original location and allowing it to receive sunlight will help ascertain whether all components are functioning optimally. Monitoring the output over several days will provide an accurate assessment of performance, establishing whether any issues remain post-repair. Such diligence not only affirms the quality of the work done but also contributes significantly to the longevity and effectiveness of the solar panel system.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON ISSUES FACED DURING SOLAR PANEL DISASSEMBLY?

Disassembling a solar panel often presents several challenges. One of the most frequent issues includes dealing with rusted screws, which can become difficult to loosen. Using penetrating oil may assist in easing these screws out, yet patience and caution are paramount to avoid stripping them. Additionally, handling the glass component needs utmost care, as it is prone to breakage. Any damage can complicate or halt the reassembly process altogether.

Moreover, potential risks include electrical shocks if the panel is improperly handled without testing for residual current. This makes it imperative to utilize a multimeter beforehand to ensure safety during disassembly. Lastly, keeping track of small components like screws and connectors is often overlooked. Organizing these items properly during disassembly impedes loss and confusion later in the reassembly phase.

HOW LONG DOES IT TAKE TO DISASSEMBLE AND REASSEMBLE A SOLAR PANEL?

The time required for disassembling and reassembling a solar panel can vary based on experience and the specific condition of the panel. Generally, a novice might take anywhere between three to five hours to complete the procedure, owing to the learning curve associated with identifying components and operating tools correctly. For someone with more experience, the process may span two to three hours.

Factors that contribute to this variability include the type of solar panel, the extent of cleaning required, and the need for potential repairs after inspection. Additionally, if unforeseen complications arise, such as damaged components requiring replacement, the overall timeframe can increase significantly. Care should always take precedence over speed to ensure a thorough and safe execution of the task.

WHAT KIND OF MAINTENANCE IS REQUIRED AFTER REASSEMBLY?

Following the reassembly of a solar panel, regular maintenance becomes essential for sustaining optimum efficiency. Performing routine inspections every few months can help identify any areas needing attention or repairs. Cleaning the glass surface periodically is vital, as dust and debris can impede sunlight absorption and diminish energy output.

Furthermore, ensure that the structural integrity of the frame and connections is periodically checked, as environmental factors such as wind, precipitation, and temperature fluctuations can degrade components over time. Timely addressing of issues discovered during maintenance will extend the life of the solar panel and enhance its energy-generation capabilities. It is also beneficial to keep a maintenance record, providing insight into the history of repairs, adjustments, and overall performance over time.

Successful disassembly and reassembly of an old solar panel is an undertaking that requires a meticulous approach and a keen understanding of its construction. This process hinges on comprehension of individual components and suitable tools to ensure effective handling. Employing appropriate safety measures to safeguard against electrical shocks and physical injuries forms the foundation for a safe experience. The disassembly sequence involves removing the frame, followed by the glass cover, emphasizing an organized workflow to aid reassembly. In inspecting components, emphasis must be placed on identifying damage that could impede performance, including testing electrical outputs to guarantee functionality. Cleaning surfaces and ensuring connections are insulated contribute to optimal electricity generation upon reassembly. Ultimately, the verification of all parts leads to an assessment of the panel’s efficiency, allowing for monitoring its output in the days following reinstallation. Regular maintenance ensures the ongoing performance and longevity of the system, affirming that diligence and care yield lasting benefits in harnessing solar energy effectively. The journey into solar panel maintenance not only enhances renewable energy adoption but also fosters a greater comprehension of environmental conservation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-the-old-solar-panel/