To disassemble and assemble solar tubes conveniently, one must follow a systematic approach that entails understanding the components involved, having the appropriate tools at hand, and adhering to safety measures throughout the process. 1. Familiarity with the solar tube system, 2. Appropriate tools such as screwdrivers and pliers, 3. Safety precautions like gloves and eyewear, 4. Detailed step-by-step procedure for disassembling and reassembling. The most critical aspect is ensuring that all components are handled carefully to avoid damage and ensure successful reassembly. When properly executed, this task can lead to efficient maintenance or replacement of solar tubes, resulting in enhanced system performance.

1. UNDERSTANDING SOLAR TUBES

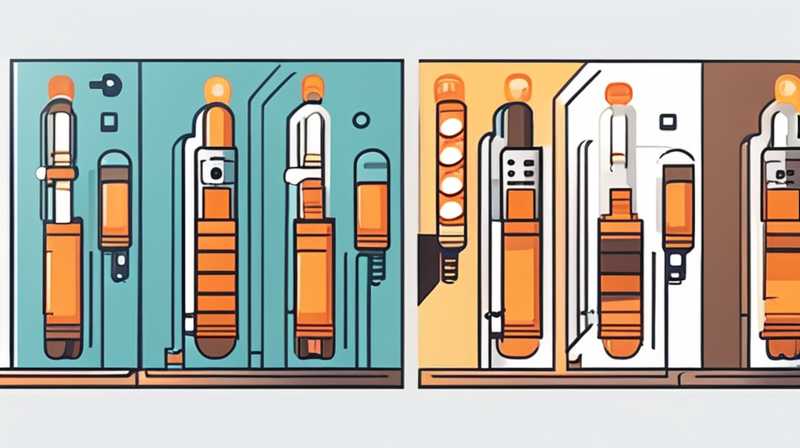

Solar tubes, also known as tubular skylights, represent an innovative solution for natural daylighting. Constructed from highly reflective materials, these tubes harness sunlight efficiently and transport it indoors, enhancing illumination in spaces that lack adequate natural light. The fundamental principle behind solar tubes involves capturing sunlight at the roof level and channeling it through a reflective tube into the living space.

One key characteristic of solar tubes is their energy efficiency. Unlike traditional skylights, which can lead to significant heat loss, solar tubes minimize temperature fluctuations within indoor environments. This energy conservation results not only in reduced heating and cooling expenses but also contributes positively to environmental sustainability efforts. Furthermore, solar tubes are quite versatile; they can be installed in various locations, from residential homes to commercial buildings, ensuring the benefits of daylighting are accessible to a broad audience.

2. PREPARING FOR DISASSEMBLY

Before engaging in the disassembly of solar tubes, it is essential to gather the necessary tools. Typical tools include screwdrivers (both flathead and Phillips), pliers, ladder, and possibly a utility knife or saw for any adjustments to the tubing. Having these materials ready will not only expedite the process but also ensure that the task is performed efficiently and safely.

Additionally, a detailed examination of the solar tube system is crucial prior to disassembly. This evaluation involves reviewing the installation manual, if available, or performing a visual inspection to identify the various components, such as the dome, the tube, and the ceiling fixture. Understanding how these parts interact with each other helps to avoid unnecessary complications during the disassembly process. Ensuring that the workspace is clean and organized facilitates a smoother operation and reduces the risk of misplacing components during assembly.

3. DISASSEMBLY OF SOLAR TUBES

Initiating the disassembly of solar tubes requires careful attention. Start by removing any fixtures or coverings that might obstruct access to the dome. Most solar tubes have a rubber or plastic trim securing the dome in place, which can be gently pried or unscrewed. It’s advisable to handle these components delicately to prevent any breakage or damage.

Once the dome is removed, focus on the tubing. Typically, the tube is fastened using screws or clamps at both the roof and ceiling ends. Removing these fasteners should be done systematically, ensuring that the tube is freed from any attachments without bending or damaging it. Utilize the appropriate screwdrivers or pliers to loosen the clamps and take extra care, particularly if the tube has been exposed to weather elements for an extended period, as rust or corrosion can complicate the process.

4. HANDLING COMPONENTS WITH CARE

Throughout the disassembly process, handling the components with due diligence is paramount. Each part, especially the dome, is usually made of acrylic or polycarbonate, making it prone to scratches and cracks if not adequately handled. Using a soft cloth to clean the dome before and after removal ensures that no debris or fingerprints compromise its performance when reassembled.

Proper storage of disassembled components is equally crucial. Organizing parts in a labeled container can prevent confusion during reassembly. Adequate separation of screws, clamps, and other small components helps mitigate the risk of losing essential pieces, potentially causing delays in the reinstallation. This systematic method contributes significantly to reducing the overall time taken for the project and ensures that no part is overlooked when reassembling.

5. ASSEMBLING SOLAR TUBES

Reassembly of solar tubes should start by placing the tubing back into position. Begin by aligning the tube correctly with the ceiling fixture; this alignment is pivotal in ensuring that light can pass through unobstructed. Once aligned, reapply any clamps or screws that were removed during disassembly, ensuring they are tightly secured.

The next focus should be the installation of the dome. After positioning the dome over the tube, carefully secure it using the previously removed trims or screws. This step may require some finesse, particularly if the trim fits snugly around the dome. Proper sealing around the dome prevents air and water leaks, which is essential in maintaining the integrity of the solar tube system over time.

6. TESTING AND FINALIZING INSTALLATION

Upon reassembly, it is essential to conduct a thorough examination of the system to ensure that all components function properly and are securely in place. Check for any gaps between the dome and the roof or ceiling, as these can lead to air leaks or moisture ingress. Addressing any discrepancies promptly is crucial for the longevity of the installation.

Finally, ensure that the solar tube is producing adequate sunlight as intended. Observe the interior space during different times of the day to verify that the desired lighting levels are achieved. Should any issues arise, revisiting the assembly process to make fine-tuning adjustments may be necessary. Confirming that the system performs optimally will maximize its efficiency and enhance the overall illumination quality in the space.

FAQs

WHAT TOOLS ARE NECESSARY FOR DISASSEMBLING SOLAR TUBES?

To undertake the disassembly of solar tubes effectively, having the right tools is essential. Typically, the toolkit includes screwdrivers (both flathead and Phillips), pliers, a utility knife for any necessary cuts to the tube, and a ladder to access the roof or the installation points. Additional tools, such as a torque wrench, may assist in tightening screws during the reassembly phase. When gathering tools, ensure that they are in good condition to prevent any mishaps during the operation.

Moreover, wearing protective gear, such as gloves and safety glasses, greatly enhances safety. This equipment protects against any sharp edges or accidental slips that could result in injury. If the solar tube has been in place for several years, corroded screws or clamps necessitate caution while removing; penetrating oils may be useful in easing these fasteners. Preparedness plays a significant role in the smooth execution of the disassembling and reassembling process.

CAN SOLAR TUBES BE DISASSEMBLED FOR MAINTENANCE?

Indeed, disassembling solar tubes for maintenance is not only feasible but often encouraged to maintain optimal functionality. Regular maintenance ensures that the light transmission remains uncompromised and that the components are free from dust, dirt, and potential damage from environmental factors. Solar tubes can accumulate debris, particularly the dome, which can obstruct sunlight and diminish their effectiveness over time.

Depending on the design and installation of the solar tube, maintenance may involve cleaning the interior of the tube and inspecting seals and fasteners for degradation. For instance, if the seals are showing signs of wear, they can lead to air leaks or unwanted moisture intrusion. Identifying these issues early allows for timely maintenance, which can prevent more extensive repairs down the line. Therefore, disassembling solar tubes periodically for maintenance checks is a beneficial practice in prolonging their lifespan and efficiency.

HOW DOES ONE ASSESS THE NEED FOR DISASSEMBLY?

Determining the need for disassembly of solar tubes typically involves observing visual cues and evaluating indoor lighting conditions. Several indicators may signal that disassembly is warranted, such as a noticeable decline in interior brightness during daylight hours or signs of moisture accumulation within the tube or around the edges of the dome. Additionally, inspection for any visible damage to the dome, tubing, or fixtures can inform a decision to disassemble.

Furthermore, routine maintenance checks provide a prime opportunity to assess the state of the solar tube system. During these inspections, one should examine the dome for scratches or cracks, inspect the tubing for blockages, and ensure that all seals remain intact. Identifying potential problems early can prevent more significant repairs and ensure that the system continues to function at its best. Therefore, being diligent in monitoring the performance of solar tubes is crucial in determining the appropriate times for disassembly and maintenance.

In Closing

Disassembling and assembling solar tubes can appear daunting initially, yet understanding the components and having the right tools can simplify the process significantly. Engaging diligently in this process not only contributes to the effective functioning of the solar tube system but also fosters an environment that maximizes daylighting benefits. A methodical approach—starting from understanding the system, preparing for disassembly, meticulously handling components, to performing careful reassembly—ensures efficiency and effectiveness.

When maintained correctly, solar tubes can provide exceptional lighting solutions while preserving energy, making them a valuable addition to homes and businesses alike. Regular inspections and maintenance can prevent common issues and extend the lifespan of the installation. Thus, mastery of the disassembly and assembly processes empowers individuals to take charge of their solar tube systems, encouraging greater reliance on renewable energy resources and promoting sustainable living practices.

In summary, a thorough comprehension of solar tube mechanisms, adherence to safety principles, and meticulous care during disassembly and reassembly enhance the system’s durability and functionality, ensuring a continuous benefit from natural lighting for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-solar-tubes-conveniently/